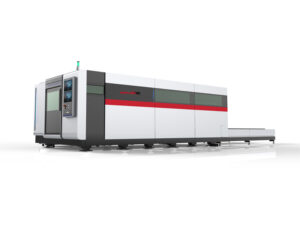

Best Fiber Laser Cutter For Sale

Table of Contents

Why Choose Fiber Laser Cutter to Cut Carbon Steel

Now more and more laser cutter for sale appear in our lives. This machine has been widely used in sheet metal processing, advertising production, hardware products, kitchenware and other industries. Various fiber laser cutter for sale, CNC fiber The laser cutting machine is loved by the society. Laser cutting is suitable for cutting steel plates and carbon steels with large thickness and long size, and has been widely used in industrial production. Efficient, stable, precise, and fast are the advantages of fiber laser cutter for sale. With this series of advantages, fiber laser for metal cutting becomes the best choice for processing carbon steel.

As a kind of high-quality alloy steel, carbon steel has been widely used in life and industry with its excellent texture. Because carbon steel contains carbon, it does not reflect light strongly and absorbs the beam very well. Carbon steel is more suitable for cutting with metal laser cutter for sale, and the processing effect is also very good. The cutting surface is flat, smooth, beautiful, easy to use, and safe. And save costs.

Laser cutting carbon steel materials mainly uses fiber laser cutting machines, but due to the high hardness of carbon steel, in order to avoid problems, it takes a long time to check and maintain fiber optic equipment. And if there is a problem during processing, it is necessary to investigate from all aspects of the laser cutting machine.

Advantages of Cutting Carbon Steel by Fiber Laser Cutter

1.Good cutting quality: good cutting quality, small cutting seam, small deformation, smooth, flat and beautiful cutting surface, no need for subsequent processing.

2.Fast cutting speed: continuous, fast curve cutting function and shortest processing path optimization function, greatly improving work efficiency;

3.High stability: The output power of the equipment is stable, the laser has a long service life, and the maintenance is simple;

4.The software is powerful: you can design all kinds of graphics and text at will for instant processing, flexible work, high efficiency, simple and convenient mechanical operation.

Problems About Fiber Laser Cutter Cut Carbon Steel

1. Abnormal sparks appear when laser cutting mild steel:

When the laser normally cuts low carbon steel, the fire bouquet is long and flat, with fewer split ends. The occurrence of abnormal sparks will affect the smoothness and processing quality of the cut section of the workpiece. At this time, when other parameters are normal, the following conditions should be considered:

The nozzle of the laser head is seriously worn out, and the nozzle should be replaced in time;

In the absence of new nozzle replacement, the cutting working gas pressure should be increased;

If the thread at the connection between the nozzle and the laser head is loose, you should immediately stop cutting at this time, check the connection status of the laser head, and reinstall the thread.

2. The reason about Laser incomplete cutting:

The choice of laser nozzle does not match the thickness of the processing board, replace the nozzle or processing board;

The laser cutting line speed is too fast, and operation control is required to reduce the line speed.

3. The reasons of burrs when processing carbon steel include:

The possible reasons include:

If the laser focus position is shifted, do a focus position test and adjust it according to the shift amount of the laser focus;

The output power of the laser is not enough. It is necessary to check whether the laser generator is working normally. If it is normal, observe whether the output value of the laser control button is correct, and adjust it if it is not correct;

The cutting line speed is too slow, it is necessary to increase the line speed during operation control;

The purity of the cutting gas is not enough, and it is necessary to provide high-quality cutting working gas;

The instability of the machine tool running for too long requires shutdown and restart at this time.

Processing Thickness of Different Fiber Laser Cutter for sale

BuyCNC can provide a variety of laser cutters for sale with different powers. As long as you tell us the material you want to process and the corresponding thickness, then we will recommend the most suitable fiber laser for metal cutting for you.

Generally speaking, the thickness limit values of different power laser cutting machines for cutting various materials are as follows:

1. The maximum cutting thickness of different materials by 2000W fiber laser cutting machine: the maximum thickness of carbon steel is 16mm; the maximum thickness of stainless steel is 6mm; the maximum thickness of aluminum plate is 4mm; the maximum thickness of copper plate is 4mm;

2. The maximum thickness of different materials cut by 3000W fiber laser cutting machine: the maximum thickness of carbon steel is 22mm; the maximum thickness of stainless steel is 12mm; the maximum thickness of aluminum plate is 8mm; the maximum thickness of copper plate is 8mm;

3. The maximum thickness of 4000W cnc fiber laser cutter for cutting different materials: the maximum thickness of carbon steel is 25mm; the maximum thickness of stainless steel is 12mm; the maximum thickness of aluminum plate is 10mm; the maximum thickness of copper plate is 10mm;

4. The maximum thickness of the 6000W fiber laser cutter for cutting different materials: the maximum thickness of carbon steel is 25mm; the maximum thickness of stainless steel is 20mm; the maximum thickness of aluminum plate is 16mm; the maximum thickness of copper plate is 12mm;

In the actual cutting process, the cutting ability of the fiber laser cutter for sale is also related to the quality of the cutting machine, laser type, cutting environment, cutting speed and other factors. The use of auxiliary gas can also improve a certain cutting ability, so there is no absolute The standard to judge its cutting thickness. such as,

1. The cutting of carbon steel mainly relies on oxygen combustion.

2. The cutting of stainless steel mainly depends on power.

Generally, the 3000w CNC fiber laser cutting machine can cut carbon steel plates of about 22mm, and stainless steel plates are slightly difficult to cut. If the cutting thickness is to be increased, the edge effect and speed must be sacrificed.

Conclusions

BuyCNC Laser Technology Co., Ltd. is one of the laser equipment technology R&D and manufacturing enterprises with vertical integration capabilities from materials, devices to complete machines. We have a detailed fiber laser price list, you can choose the machine according to your budget, after all, the price of laser cutting machine is more expensive. Our fiber laser cutter for sale is equipped with advanced fiber laser cutting system kit, which can meet most of the needs of the laser processing industry. If you have special needs, BuyCNC can also provide you with customized fiber laser cutter for sale.

With its high brand awareness, R&D and design capabilities, complete manufacturing technology, and strict quality control in the industry, BuyCNC has now become a professional laser equipment manufacturer with a complete range of manufacturing laser equipment, wide applicability, and technology research and development capabilities that have reached the leading level in China. One of the enterprises.

Related Blogs About CNC Fiber Laser Cutter

BuyCNC 12000w Fiber Laser Cutting Machine Shipped Successfully

BuyCNC

Laser Cutter For Metal Signs Help Advertising Industry

Laser

Why Choose China Fiber Laser Cutting Machine Manufacturer

Why

Fiber Pipe Laser Cutter Is Popular In Door And Window Industry

Table