Table of Contents

How much is the price of 10000w fiber laser cutter?

The 10000w fiber laser cutter is a 10,000-watt fiber laser cutting machine, which is mainly used for cutting thick metal sheets. A common sense in life is that the higher the configuration, the more expensive the price. The high-power 10000w fiber laser cutting machine has a higher configuration, and the price is definitely higher than that of the medium and low power. Is the price of the 10000 watt fiber laser cutter expensive, and how much does it cost?

First of all, the price of the laser generator itself is relatively expensive. Secondly, the higher the power of the laser generator, the more expensive it is. The thicker the metal material, the higher the power of the laser generator is needed, such as the fiber laser cutter 10000 watt is used. The higher-power laser generator is available, so the cost of the fiber laser cutting machine will be higher, and the price will be more expensive accordingly. The general price of a 10000w fiber laser cutter is around US$100,000.

Whether to buy a fiber laser cutting machine 10000 watt also depends on the material and thickness of the manufacturer’s cutting. Different brands of lasers may have different effects, but the ability to cut the thickness is basically not very different. The 10000 watt fiber laser cutter can cut metal sheets of about 20mm. If the main cutting is thin metal sheets, it may be less used when the 10,000-watt level is used.

But also think that 10000 watt fiber laser cutter can cut more thickness materials, 1000w can not do 10000w work, but 10000w can do 1000w work, cutting manufacturers should not ignore the future because of the small scope of cutting. Development, abandoning the big fish to take the small fish, this is not worth the loss.

10000w fiber laser cutter is widely used in automobile industry, advertising industry, kitchen utensil industry, sheet metal processing, cabinet industry, fitness equipment and other industries. Companies use laser cutting machines.

The 10000w fiber laser cutting machine is one of the most representative intelligent processing equipments in the contemporary era. It has excellent processing effect and needs to be used in many fields. Often, a single laser cutting machine can bring huge benefits to users. Nowadays, the prices of laser cutting machines on the market vary, and users often feel “dazzled” when choosing, so what factors determine the 10000w fiber Laser cutter price, how should users buy it?

Factors affecting the price of 10000 watt fiber laser cutter:

1. The brand of the laser cutting machine: Of course, the size of the brand determines the price of the equipment, which is a relatively abstract concept. We can understand it this way, big brands are much more secure than small factories in terms of equipment quality, equipment spare parts, equipment performance, technology including after-sales service, these are an added value of products, and also laser cutting It is a general law of the machine market, so the price of fiber laser cutting machines of big brands will be higher than that of small brands.

2. Machine tool format: 10000w fiber laser cutter generally has several standard format sizes, and according to the special needs of customers, non-standard machine tools that meet the customer’s size can also be customized. The standard size is the specification that the manufacturer has always produced, and the non-standard size needs to be specially customized, so the customized format is more expensive than the standard format. The cutting machine formats currently produced by Honglei Laser are generally 3013, 3015, 4015, 4020, 6015, 6020, and 6025, which basically cover all processing needs on the market.

3. The brand of the laser: As we all know, the laser is the core optical component of the laser cutting machine. The brands of the laser cutting machine are different, the beam quality is also very different, and the price of the laser also varies greatly with the brand. For example, BuyCNC uses Raycus lasers and IPG lasers, and domestic lasers are relatively much cheaper than imported ones. At present, imported lasers are superior to domestic lasers in terms of stability and beam quality. The laser can be selected by the customer

4. Other key components of the 10000 watt fiber laser cutter: Other key components such as guide rails, racks and pinions, servo motors, etc., their brands and quality are also the reasons for the different prices. Therefore, BuyCNC reminds users to pay attention to the specific configuration when purchasing a laser cutting machine, and not to be blindly tempted by low prices. The key components of BuyCNC’s laser cutting machine are all industry-leading brands, and the quality is guaranteed. trustworthy

5. Power: Manufacturers of the same brand, the higher the equipment power, the higher the price. Therefore, before making an inquiry, you must know the material and thickness you want to cut, as well as your needs for cutting speed and production capacity. At present, the power of laser equipment produced by Honglei Laser is 500W-12000W, which can meet your basic processing needs.

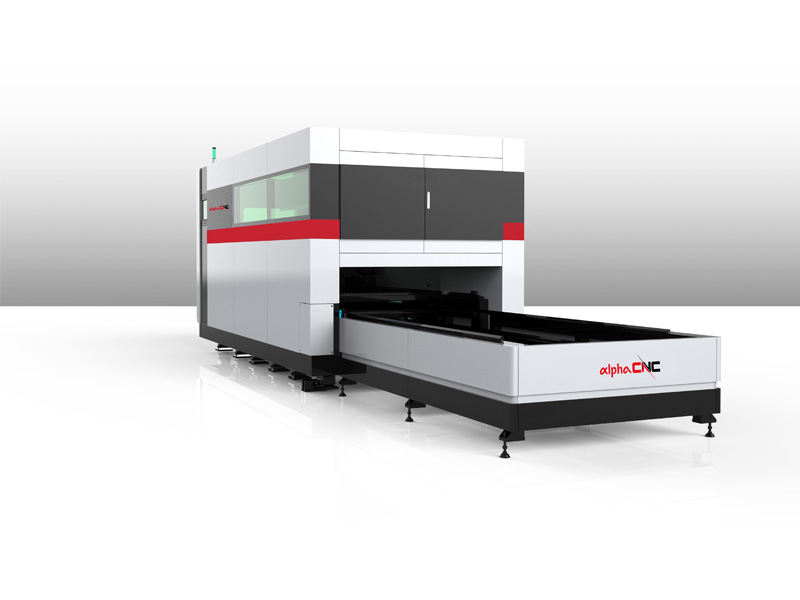

BuyCNC Provide you the best 10000w fiber laser cutter

Now there are many 10000w fiber laser cutter manufacturers, and the production technology and quality of the fiber laser cutter 10000w machines provided are also different, which also makes the price of laser cutting machines inconsistent. Secondly, the power of the laser cutting machine is different, and the price is naturally different. In addition, there are many types of laser cutting machines, such as 3D laser cutting machines, stainless steel laser cutting machines, round tube laser cutting machines and other equipment, each of which will have a different price ratio.

Generally speaking, the popularity of the brand can easily induce customers to purchase a fiber laser cutter 10000w machine. In fact, when purchasing a 10000w fiber laser cutter, users should combine the three aspects of brand, power and after-sales service to make a choice. In addition to having a good reputation, an excellent laser cutting machine manufacturer should also have more laser cutting machines with different powers to allow customers to choose equipment according to their own needs. In addition, considering the use of equipment, good after-sales service is also It is very important that customers will feel a better product operation experience.

BuyCNC is an enterprise specializing in the production and development of metal laser cutting machines in China, and it is a benchmark enterprise in the domestic laser cutting machine production field. After years of research, development and innovation, the laser equipment developed and produced has high electro-optical conversion efficiency, good beam quality, stable performance and high cost performance. Many technologies are in the leading position in the domestic industry. The laser equipment produced is sold well in many large and medium-sized key production enterprises and listed companies all over the country.