Best CNC Machines For Sale

1.What is a CNC Machines?

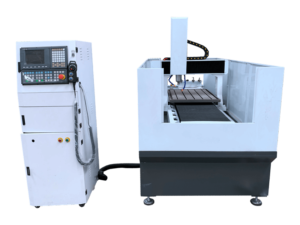

CNC machine is an automatic computer numerical control machine tool with multiple functions such as cutting, engraving, carving, milling, drilling, slotting and turning. It is suitable for hobbyists, amateurs, small enterprises, small stores, family enterprises, home stores, school education and industrial manufacturing. A CNC machine consists of frame, numerical control controller, spindle, gantry, numerical control operating system, numerical control software, switch, rack and pinion are composed of motor, driver, T-slot worktable or vacuum worktable, ball screw, guide rail, power supply, collet, vacuum pump, limiter, etc. CNC refers to the idea that machine tools are controlled by computers rather than manually by mechanics. The new machine tools in CNC programming enable the industry to continuously produce parts with precision unimaginable a few years ago. If the CNC program is properly prepared and the computer is properly programmed, the same part can be copied multiple times with the same accuracy. It controls the automatic execution of the operation instructions of the machine tool, with high speed, high precision, high efficiency and repeatability. CNC machines are also known as CNC machinery, CNC machine tools, computer-controlled machine tools, C and C machines, CNC processing tools, CNC kits, CNC mask machines, CNC equipment, CNC power tools, CNC cutting machines, digital machines, CNC cutting machines.

2.How do CNC machines work?

CAD refers to computer aided design, which is used for 2D or 3D workpiece or 3D design. Cam stands for computer aided manufacturing, which is used to generate G-code. The full name of CNC is computerized numerical control. CNC controller of the CNC machine can read G-code and start machining. In modern CNC operating system of CNC machine, the design of workpiece highly depends on software such as computer aided design (CAD) and computer aided manufacturing (CAM). Computer aided manufacturing software analyzes and designs the model and calculates the motion instructions in the CNC machine machining process. The motion instructions and other auxiliary instructions required in the machining process are converted into the format that can be read by the NC system through the post processor of the CNC machine. The generated file is loaded into the CNC machine tool for workpiece processing. After the program instructions are input into the memory of the CNC system, the computer compiles and calculates. Through the displacement control system of CNC machines, the information is transmitted to the driver to drive the motor to cut the designed parts.

Step 1: Design 2D or 3D drawing through CAD software.

Step 2: Convert the CAD file into G code through CAM software.

Step 3: set up the CNC kit.

Step 4: Start CNC programming.

Step 5: Start CNC machining

3.How many types of CNC machines are there?

According to the type, six most common types of CNC machines can be found in the manufacturing industry: CNC milling machine, CNC router machine, CNC laser machine (laser cutting machine, laser engraving machine, laser engraver, laser etching machine, laser marking machine and laser welding machine), CNC digital cutting machine, CNC lathe, plasma cutting machine.

According to end use, there are 3 basic types: Home CNC machine tools, hobby CNC machine tools (mini series, small series, desktop series, desktop series, desktop series, portable Series) and Industrial CNC machine (wood, stone, metal, foam, plastic).

According to the function, there are 10 common types, such as CNC cutting machine, CNC milling machine, CNC routing machine, CNC engraving machine, CNC carving machine, CNC slotting machine, CNC sanding machine, NC nesting machine, CNC turning machine, CNC drilling machine, etc.

According to the materials, It is divided into woodworking CNC machines, metal CNC machines, foam CNC machines, stone CNC machines and so on.

4.What are the CNC machines used for?

CNC is a technology that uses digital information to control mechanical motion and working process. Numerical control equipments are mechatronics product formed by the penetration of new technology represented by numerical control technology into traditional manufacturing industry and emerging manufacturing industry. CNC technology and equipment is the enabling technology and the most basic equipment for the development of emerging high-tech industries and cutting-edge industries. CNC technology is widely used in material processing industry, information industry, biological industry, aerospace and other national defense industries all over the world to improve manufacturing capacity and level, and improve market adaptability and competitiveness. Industrial developed countries also list CNC technology and numerical control equipment as national strategic materials. While developing their own CNC technology and industry, they blocked and restricted the “highly complex” key numerical control technology and equipment.

Therefore, vigorously developing advanced manufacturing technology with numerical control technology as the core has become an important way for developed countries to accelerate economic development and improve their comprehensive national strength and national status. CNC machines are mechatronics products integrating mechanical, electrical, hydraulic, pneumatic, microelectronics and information technology. It is a working machine with the advantages of high precision, high efficiency, high automation, high flexibility, stable and reliable processing quality and so on. The technical level of CNC machine tools and its proportion in output and total ownership are one of the important indicators to measure the national economic development and the overall level of industrial manufacturing of a country.

5.Characteristics and advantages

Operation and monitoring of the CNC machines are completed in the CNC system. The CNC system is the the brain of CNC machinery. Compared with ordinary machine tools without CNC system, CNC machine tool kits have the following characteristics:

1.The CNC machine has strong adaptability to the characteristics of single piece production of processing objects and molds, and provides a suitable processing method for mold making.

2.The CNC machine itself has high precision and good rigidity. CNC machine can choose favorable processing capacity and high productivity (generally 3 ~ 5 times that of ordinary machine tools).

3. Automatic CNC machine reduce labor intensity.

4.The CNC machine has high precision and stable quality.

5.When the processed parts change, generally only the CNC program needs to be changed, which can save the production preparation time.

6.The CNC machine can run multi coordinate linkage and make parts with complex shapes.

7.It is conducive to the modernization of production management. They use digital information and standard codes to process and transmit information, and use computer control methods to lay the foundation for the integration of computer-aided design, manufacturing and management.

8.CNC machine is High reliability.

High quality requirements for operators and high technical requirements for maintenance personnel.

6.How do beginners use CNC machine tools?

There are nine basic steps for operating CNC machine:

Step 1. Edit and enter a CNC file: Before processing, analyze and compile the CNC files of the CNC project. If the CNC files are complex, do not program on the CNC machine, but use the programmer or computer to program, and then back up to the CNC control system through USB flash disk or communication interface. This can avoid increasing the auxiliary time of machining when using the CNC machine.

Step 2. Turn on the machine: Generally, turn on the main power supply first to make the CNC machine ready for startup. Start the CNC system with one key and the CNC machine starts at the same time. The information is displayed on the CRT of the CNC control system. At the same time, check the connection status of hydraulic, pneumatic, input shaft and other auxiliary equipment of the CNC machine.

Step 3. Entity reference point: Before machining, establish the motion origin of each coordinate of the CNC machine. For machines with a control system, perform this step first.

Step 4. Input and call of CNC program: According to the program medium (USB flash disk), it can be input through computer, programmer or serial port communication. If it is a simple program, it can be directly input on the CNC control panel with the keyboard, or it can be input section by section in MDI mode for segmented processing. Before machining, the engineering origin, tool parameters, offset and various compensation values in the machining program must also be input.

Step 5. CNC program editing. To modify the input program, place the operating mode selector switch in the edit position. Use the edit keys to add, delete, and change.

Step 6: Check and debug the CNC program: First lock the CNC machine and only run the system. This step is to check the program. If there is an error, it needs to be edited again.

Step 7. Project installation and alignment: Install and align the lower part to be machined and establish the datum. This method uses manual incremental movement, continuous movement or handwheel to move the machine. Align the starting point to the beginning of the program and set the tool reference.

Step 8. Start the coordinate axis for continuous machining: Continuous processing generally adopts the program processing in memory. The feed speed in CNC machining can be adjusted through the feed rate switch. During machining, you can press the feed hold button to pause the feed movement, observe the machining condition or conduct manual measurement. Press the cycle start button again to resume machining. In order to ensure the correct procedure, recheck before processing. In the milling process, for plane curve engineering, pencil can be used to draw the engineering outline on paper instead of tools. This is more intuitive. If the system has a tool path, the simulation function can be used to check the correctness of the program.

Step 9. Turn off the machine: After machining and before turning off the power supply, pay attention to check the status of CNC machine tool and the position of machine tool parts. Turn off the CNC machinepower first, then the system power, and finally the main power.

7.How Much Does A CNC Machine?

The CNC machine price is very different depend on the different machine configurations. Usually you will get CNC machines prices ranging from $2000.00USD to $30000.00USD. If you want to buy CNC machine overseas, the final price should include freight, taxes and customs clearance fees. CNC Router Machine costs range from $2,300.00 to $200,000.00, CNC milling machine costs range from $2,000.00 to $150,000.00, CNC laser engraving and cutting machine costs range from $2,300.00 to $280,000.00, and CNC lathe costs range from $2,800.00 to $12,180, CNC plasma cutting machine price is from $3,000.00 to $30,000.00.

8.How To Use A CNC Router Machine?

The following are the different table size of the CNC machine for sale:

4040 CNC machine for sale, 6060 CNC machine for sale, 6090 CNC machine for sale, 6012 CNC machine for sale, 9012 CNC machine for sale, 9015 CNC machine for sale, 1212 CNC machine for sale, 1313 CNC machine for sale, 1318 CNC machine for sale, 1325 CNC machine for sale, 1525 CNC machine for sale, 1625 CNC machine for sale, 1530 CNC machine for sale, 2030 CNC machine for sale, 2130 CNC machine for sale, 2131 CNC machine for sale, 2040 CNC machine for sale, 2140 CNC machine for sale, 2141 CNC machine for sale.

9.How to buy a CNC machine?

Now there are many kinds of CNC machines on the market, and there are many brands and manufacturers too. This phenomenon has both advantages and disadvantages for buyers to buy the CNC machine. The advantage is that consumers have more choices and can compare and buy CNC machines with higher cost performance. The bad aspect is hat they have no choice but to buy one.

When customer go to see the CNC machine, it is possible that one seller is cheaper than another, and the price of the last one is more attractive. At this time, driven by the salesperson, customer bought the CNC machine on impulse. However, when the CNC machine was used later, it was found that the cheap CNC machine was not easy to use, the accuracy was not high, the operation was unstable, and it was often repaired.

If you meet sellers with better service, you can also meet some sellers with poor service awareness. It’s a headache. Any problem during the warranty period is said to be caused by man. You have to take the money, and then you have to take the money. This kind of seller is in trouble. As the saying goes, cheap goods are not good goods, and good goods are not cheap. If you encounter a CNC machine that is much lower than the market price, it’s best for someone who doesn’t know what to do.

The so-called layman watching the excitement, the expert watching the door. The price of the machine is too cheap. Having said so much, what factors should we pay attention to when purchasing CNC machines?

1. Clarify the nature of processed products

We should not think that a CNC machine can do all kinds of work. CNC machine manufacturers divide CNC machines into many types to professionally process different materials. If you want to buy a CNC milling machine to engrave bakelite, or buy a large industrial CNC machine to cut small handicrafts, it will not only waste a lot of money, but also have a poor effect.

Similarly, if you buy a desktop CNC machine for home door production, it may not work at all. So before buying the CNC machine, you must communicate clearly with the salesperson of CNC machine to let him know your purpose, including the size, material and processing effect of the workpiece.

2. Select the type and model of the CNC machine according to your needs.

For example, if you buy a CNC machine for an advertising sign shop for the first time, which is mainly used to produce 3D letters light plates, crystal letters, double-color plates, badges, etc., you should choose professional amateur CNC machine for advertising customization configuration. If the double-color plate is processed, the floating cutter head needs to be configured to ensure the consistency of word depth at the time of engraving on the large-scale double-color plate.

If you need to turn wood, you should choose a CNC lathe for wood turning. If you are mainly use the CNC machine for mold making, you need to choose a CNC milling machine, and then determine the model of the CNC milling machine according to your milling size. If the material to be processed is mainly graphite, we must buy a special CNC milling machine for graphite, because the protection level of ordinary CNC machine is not enough, which will cause damage or even paralysis of the machine tools.

Therefore, we must choose professional CNC machine according to our own CNC machining schemes and projects.

3.Proofing test before purchase

After selecting the model, before purchase, in order to ensure the reliability of the CNC machine and measure the return on investment, customer must let the salesperson or do it yourself to make on-site proofing and calculation for the products you most often use.

The advantage to do it is that you can intuitively see the effect of machining and the timeliness of output. A comprehensive understanding of the performance of the CNC machine really makes it clear to you at a glance.

4.Signing of the contract

After the above 3 points are completed, the purchase contract must be signed. A professional contract is the best way to protect one’s legitimate rights and interests.

First of all, the contract shall clearly indicate the CNC machine’s model, configuration, price, delivery time and delivery method, training method, warranty terms and specific payment method. After the contract is signed, the advance deposit is generally paid according to the contract. For the signed contract, we must abide by its contents to avoid unnecessary conflict in the future.

5.Delivery and training

After the CNC machine is delivered on time, the supplier’s technicians usually unpack the machine for inspection (if the manufacturer’s technicians arrive at the same time, there may be only simple packaging).

After the CNC machine is powered on, carefully check whether the appearance of CNC machine is damaged and whether it is damaged by impact during transportation. If no abnormality is found, please check the machine configuration and attached accessories according to the packing list and contract terms.

Next, let the supplier’s technicians install the machine (including the hardware installation of the fuselage, placing the CNC machine, turning on the CNC machine power,CNC machine software installation, whether to configure the computer, and installing optional processing software).

After installation, use the processing program provided by the manufacturer to test the sample on the CNC machine. If the finished product is normal, the delivery inspection can be completed. According to the contract, the user shall pay the balance payment. CNC machines operators are required to have a strong sense of safety responsibility, and must have skilled CNC machines operation skills before taking office.

In the training process, we should skillfully select different carving speeds and use different tools for different materials. This often requires the accumulation of experience. A good grasp is conducive to prolonging the service life of machines and tools.

6.After-Sale Service

Problems during use and after-sales service guarantee. If you encounter problems during use, you must contact the CNC machine seller first, communicate clearly, understand the problems, and don’t deal with them yourself. This may cause the supplier not to give warranty, or may cause accidents without knowing the CNC machine. In terms of after-sales service, we can require the manufacturer to strictly follow the contract. If you encounter intentional delay or bad attitude, you can complain to the person in charge.

The above six aspects are the precautions summarized by BuyCNC for purchasing CNC machine. We hope to help you buy the suitable machine. We hope you can buy the good machine you want to buy. If you have more questions about CNC machine tools, please feel free to ask for help. If you need any further help, please let us know.

CNC Wood Router For sale

CNC Metal Router For sale

ATC CNC Router For sale

Customer reviews and testimonials of CNC Machine For Sale

Tim From America

Hi BuyCNC, I’m your old friend Tim. I’m very satisfied with the 1325 CNC wood router machine I bought this time. The performance of this machine is better than the ones I bought from other Chinese CNC machine suppliers, and the price is even higher. Cheap. I have been using it for more than two months and there is no malfunction, thank you very much.

James From Canada

Hi BuyCNC, this is my reply to you one month after I bought your stone CNC router. I like this red stone CNC machine very much. It is not only good-looking, but also very convenient. I can quickly use it to complete the carving of the stone. The quality of the knives included with it is also very good, and these knives are not damaged even when cutting hard stones. I am very satisfied with this CNC machine.