BuyCNC STONE ROUTER MACHINE

CNC stone Router For Sale

Showing all 11 results

1. What is a Stone CNC Router?

The stone CNC router is a machine tool computer-controlled and it is specially designed for all kinds of stone processing, such as marble, granite, sandstone, jade, quartz, etc. The stone CNC machine can do various processes such as carving, cutting, engraving, milling, punching, trimming, polishing, and so on. So the CNC stone router is also called: CNC stone machine, stone CNC router, CNC stone carving machine, CNC stone engraving machine, CNC stone cutting machine, tombstone engraving machine, headstone engraving machine, etc. As a stone CNC cutting machine. The stone CNC machine can meet the requirements of personalized home decoration and tooling art design. It can be used as advanced engraving processing equipment for decoration companies, handicraft industry, stone industry, the funeral industry, inscription industry, and ceramic companies. Recently, stone engraving machines have become more and more popular and welcome.

2. Application of CNC stone carving machine

The CNC Stone carving machine can process almost all stones, so as long as it is an industry involving stone, Our CNC Stone carving machine can be used. Next, I will introduce to you the application industry of CNC Stone carving machines.

Stone industry: carving and processing stone, jade, marble, granite, quartz, artificial stone, and other stones.

Furniture industry: countertop, bartop, floor tiles, marble cabinets, stone furniture.

Decoration industry: stone gift boxes, stone crafts, stone decorations, sculptures, 3D stone crafts, etc.

Stone tablet processing industry: stone tablet making, sarcophagus, tombstone, etc.

Advertising industry: stone advertising, artistic relief, signs, badges, etc.

Ceramic industry: all stone ceramics, ceramic bottles, and other handicrafts.

Applicable materials: marble, granite, quartz, jade, bluestone, black stone, etc., as well as non-stone materials such as ceramics, glass, plexiglass, PVC board, aluminum-plastic board, bamboo, and wood. Hardstone such as granite can be carved in layers to 5mm

Marble, bluestone, etc. can be carved up to 5mm at a time.

3. The configuration of the CNC stone engraving machine:

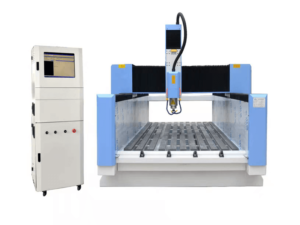

1). Low configuration small CNC stone engraving machine (low configuration): The small CNC stone machine is lightweight, and the working size is usually less than 1300x2500mm, the most popular size is 600x900mm, 600x600mm, or 600x400mm. It is usually for jade carving or some small stone crafts, such as jade pendants, small stone Buddha statues, etc. The main configuration for the small CNC stone machine is with XYZ axis ballscrew drive, cast iron machine bed, 3kw spindle, stepper motor, it is with low price.

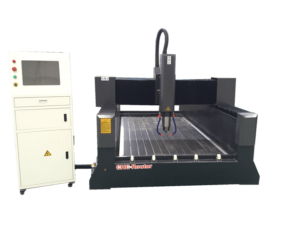

2). The Medium configuration stone CNC engraving machine: This is the most common stone CNC engraving machine in the market, and the price is moderate, suitable for most stone processing enterprises, such as the funeral industry, monument industry, stone decoration industry, etc. The medium-sized stone engraving machine generally adopts a steel pipe welded bed, square rail, stepper motor with larger torque or a hybrid servo motor, helical rack, and so on. The most popular size is 1300x2500mm, or 1500x3000mm. The Stone CNC engraving machine working speed of the medium configuration is about 3000mm/min.

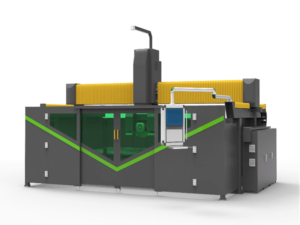

3). High configuration CNC stone router: Heavy-duty stone CNC machine has a T-shaped bed for seamless welding of generous square tubes, steel gantry, servo motor, 7.5kw spindle, and more advanced CNC controller. The working speed of the machine can be 10000mm/min.

4. Maintenance of stone engraving machine

Because the stone CNC router is a sophisticated high-tech CNC machine, in order to ensure the normal operation of the CNC machine for stone carving and extend the service life of the machine, we must maintain the CNC stone machine at all times.

1. The continuous running time of the CNC stone carving machine should be less than 10 hours per day to ensure the cleanliness of the cooling water and the normal operation of the water pump. The water spindle motor must not be lacking in water, and the cooling water should be replaced regularly to prevent excessive water temperature. If the working environment temperature is too low in winter, the water in the water tank can be replaced with antifreeze.

2. Every time the CNC machine for stone carving is used, pay attention to cleaning. Be sure to clean up the dust on the platform and transmission system, and lubricate the transmission system (X, Y, Z axis) regularly (weekly). (Note: The X, Y, Z three-axis polished rods are maintained with oil; the screw part is added with high-speed butter; if the working environment temperature is too low in winter, the screw and polished rods (square rail or round rail) should be washed and cleaned with gasoline first, And then add oil, otherwise it will cause excessive resistance in the transmission part of the machine and cause the machine to misalign.)

3. When performing maintenance and inspection on the electrical box of the stone engraving machine, be sure to cut off the power supply, wait until there is no display on the monitor and the main circuit power indicator light goes out before proceeding.

5. Structural features of Best Stone CNC machine

There are so many different kinds of wood CNC routers but how do choose a suitable machine from so many different CNC Wood Router? The following are some tips on how to choose a CNC Wood Router Machine:

1. Your budget: Your budget determines what level of Best wood CNC machine you will buy. Generally speaking, the higher the budget, the more kinds of wood CNC router you can choose. Of course, your budget should be scientific. If you want to buy an industrial Nesting CNC Machine, your budget should be at least about $20,000. If your budget is only 2,000 US dollars, then you can only buy a 3D wood carving machine just for Hobby.

2. Your products: Different wood engraving machines are suitable for making different products. You should choose wood engraving machines according to your product. For example, if your product is a dog tag, small interior decoration products, small advertising words, etc., then a small and cheap machine can meet your needs, such as a 2x4ft wood carving machine, the price is about $3,000. But if you use a 4x8ft board, you need a wood carving machine of at least 4×8 to be able to use it, and the 3D wood carving machine’s price is about $5,000. If you want to process cabinets in large quantities, an ATC wood engraving machine can help you improve efficiency. The price of an ATC machine is about $15,000.

In short, what kind of wood engraving machine you choose depends on the product you want to make and your budget. If you have any questions, please contact BuyCNC, BuyCNC will give you reasonable suggestions.

6. How to choose the best stone CNC machine?

The price of a heavy-duty stone engraving machine depends on the size and configuration of the stone CNC router machine.

One of the goals of many customers who choose 3d stone carving machines is to produce stone tablets, reliefs, three-dimensional dragon pillars, stone lions, etc.

How to choose the right CNC stone carving machine for sale before buying?

The following is a brief introduction: When purchasing a marble headstone engraving machine, you should pay attention to the following points:

First of all, what should be considered is the power of the 3d stone carving machine. Because the hardness of the stone is relatively large, usually, the stone carving machine needs to be equipped with a larger spindle motor than the advertising engraving machine and wood engraving machine in order to carry out high-intensity work.

Second, the speed adjustable range of the spindle motor of the stone cutting router, the general adjustable speed range is several thousand to 30,000 revolutions per minute, if the speed is not adjustable or the speed adjustable range is very small, then the application of this cheap stone cutting machine The range will be greatly affected because different materials must be engraved with different engraving speeds.

Third, the solidity of the stone carving machine base, the material carved from stone is relatively heavy, and the CNC stone cutter is required to have a good load-bearing capacity. It is best to adopt a heavy-duty reinforcement design, so that the CNC stone machine has a small swing and a low scraping rate, thereby improving the efficiency of engraving.

Fourth, the cooling and dust-proof system of the stone carving router machine. The stone carving process will produce high temperatures and a lot of dust, so this CNC stone machine should have good heat dissipation and dustproof functions.

Fifth, the controller of The CNC stone router.

Controllers are generally divided into two categories: a controller is just a driver, and all calculations are done by the computer. When the engraving machine is working, the computer is in a waiting state and cannot perform typesetting.

Another type of controller is controlled by a single-board computer or a single-chip computer. This kind of controller is actually a computer, so as long as the granite cutting machine starts to work, the computer can immediately perform other typesetting work, especially when engraving for a long time. The advantages are particularly obvious.

Sixth, screws and guide rails are also an important part of AAA. When using the marble engraving machine for a long time, good screws and guide rails are the guarantees of accuracy and performance.

Seven, please try carving before buying.

Regardless of the type of CNC stone machine purchased, the user should go to the manufacturer for on-site investigation or ask the manufacturer of the CNC router machine for proofing. To test whether the performance of this stone CNC carving machine can meet the demand.

BUYCNC CO, LTD. As the top supplier of China’s leading CNC router machine, we have a variety of stone CNC router machines for You to choose from, and there are many experienced engineers to provide you with after-sales service. We will provide you with the most cost-effective stone CNC router machine and service.

Customer reviews and testimonials of wood CNC Router

1. Macker Chandler

From the USA

10. Oct 2021

I bought my first CNC stone cutting machine for sale at BuyCNC. The processing capacity of this machine is satisfactory to me. I like this stone-cutting CNC machine very much.

2. Ronaldo Sanchez

From France

9. Oct 2021

In order to be able to process thicker stones, I bought a large stone CNC router from BuyCNC, this big stone carving machine can perfectly engrave almost all stones.

3. Jason Wilson

From the United States

5. Oct 2021

The stone CNC machine is very convenient to use. With the help of an engineer, I mastered the basic operation of this CNC stone machine in one day.

4. Jacob Muller

From Germany

3. Oct 2021

The work efficiency of This CNC machine stone carving router is twice that of my previous machine, so I can get more orders, I am very happy.

5. Mr. Kirk Miller

From the United States

Sep. 11, 2021

The shipment is fast, the best wood CNC machine is packaged as a whole, no assembly is required, which is better than expected. I recommend this wood CNC milling machine to you.

6.Hlomphang Bernad Ramot

From South Africa

Sep. 8, 2021

The CNC engraving machine for stone can allow my workers to process the stone in a safe environment.

7.Gheorghe Clima

From Portugal

Sep. 3, 2021

The stone engraving machine price is the cheapest price of the same small stone engraving machine I have seen.

8. Max Kontiev

From Russia

Sep. 1, 2021

This CNC stone cutting machine is more advanced than my local stone cutting CNC router, and the price is cheaper.

9. Mr.David Nardoo

From Australia

Aug. 20, 2021

The engraving ability of this engraving stone machine is too strong, it can help me process hard limestone, which expands my processing range.

10.Héctor Montejo

From Mexico

Aug. 8, 2021

My friend recommended this stone mill machine to me. This stone mill machine is indeed better than my previous CNC stone engraving machine.

11. Sergey Kostyugov

From Bulgaria

Jul. 15, 2021

The 3d stone carving machine helped me to process the 3d stone tablet that is the most troublesome for me. I used to use two machines to process it. I didn’t expect the 3d stone CNC router machine to do this work alone.

12. Behrouz Aryanapour

From Germany

Jul. 2, 2021

The CNC stone router machine allows me to process more stones in one day, which greatly improves my work efficiency.

13. ALEJANDRO GONZALEZ

From Colombia

Jun. 12, 2021

This is the most professional industrial stone cutting machine I have ever seen, it can process all kinds of stone.

14. Vladislav Istrashkin

From Estonia

Jun. 1, 2021

The five-axis of the 5 axis stone CNC machine can process my stone. This 5 axis CNC stone cutting machine can complete 3D engraving, plane engraving, and many other engraving processes.

15. Bayley Chris

From Australia

May. 18, 2021

The CNC stone cutting machines are bought after a long time on Google because BuyCNC provides more comprehensive services.

16. Ibrahim Alkbriti

From Saudi Arabia

May. 3, 2021

The installation of this 5 axis stone CNC machine is very simple. My friend and I completed the assembly in a few hours.

17. Mr. Mihai Chitic

From Romania

Feb. 23, 2021

In order to be able to process large stone slabs, I specially purchased a stone engraving CNC router machine with a large countertop.