Affordable Laser Cutter For Sale

Table of Contents

What is the Best Laser Cutter

The best laser cutter machine is to focus the laser light emitted from the laser into a high-power density laser beam through the optical path system. The laser beam irradiates the surface of the workpiece to make the workpiece reach the melting point or boiling point, and the high-pressure gas coaxial with the beam blows away the molten or vaporized metal.

working principle

Laser cutting is a manufacturing process. It consists of a very thin, invisible but focused laser beam that cuts and engraves the material. It can be used not only to cut materials, but also to engrave logos, patterns, designs and write text or numbers. The following information is obtained using the engraving option of the laser cutting machine. Lasers are ideal for processing on metal, wood, glass, ceramics, paper and stone. Although other cutting machines rely strictly on one substrate, lasers have a wide range of applications.

Features

Laser cutting processing is to replace the traditional mechanical knife with an invisible beam. It has the characteristics of high precision, fast cutting, not limited to cutting patterns, automatic typesetting, saving materials, smooth cuts, and low processing costs. It will be gradually improved or replaced. Traditional metal cutting process equipment.

The mechanical part of the laser cutter head has no contact with the workpiece, and will not scratch the surface of the workpiece during work; the laser cutting speed is fast, the incision is smooth and flat, and generally does not require subsequent processing; the cutting heat affected zone is small, the plate deformation is small, and the slit is narrow ( 0.1mm~0.3mm); the incision has no mechanical stress, no shearing burr; high processing accuracy, good repeatability, no damage to the surface of the material; CNC programming, can process any plan, can cut the entire board with a large format, without Opening the mold saves time and economy.

How to Choose Best Laser Cutting Machine

Now laser engraving machines have been widely used in different fields, and there are many laser engraving machines on the market. So, how to choose the best laser cutting machine? I think we need to seriously consider the following points:

1. Engraving materials:

First of all, we have to determine the type of material to be engraved. At present, the CNC laser engraving machine market can be roughly divided into non-metal laser engraving machine and metal best laser cutter. The former is specially used for engraving and cutting of non-metallic materials, and the latter is specially used for the processing of metal materials. The prices of these two best laser cutters are quite different.

2. Laser power:

After determining the material, we need to select the appropriate laser power according to the material to be processed. For some materials (acrylic, two-color plates, etc.), high-power laser tubes are not required, but for some other materials (such as stone, wood and other harder materials), higher power is required. Power is an important factor affecting the price of laser cutting machines. The greater the power and the higher the price, the higher the working efficiency of the product. Therefore, buyers can choose the cost-effective best laser cutter based on their personal needs assessment.

3. Working size:

Different application industries require best Karl machines with different working sizes. Generally, laser engraving machines with models of 6040, 9060, 1290, 1390, 1490, 1610, 1612, 1812 can be used. For example, the working size of Type 6040 is 600*400mm. Different work sizes and different prices. Therefore, choose a suitable laser engraving machine according to the purpose of the work, for example:

(1) Rubber pads, rubber sheets, carton boards: most laser engraving machines can be used to engrave on rubber sheets. This material does not require some special and fast machines, so it is recommended to use a laser engraving machine suitable for engraving rubber sheets, which is your best laser cutter. The price is lower, the investment is small, but the return is fast.

(2) Greeting cards, paper-cut gifts, crafts, small ornaments, wooden boxes, wine boxes, bamboo tubes, tea tubes, crystal glass ornaments, acrylic crafts, bamboo crafts, etc. Choose a small machine, such as 9060 laser engraving machine (900X600mm), which is very competitive in price, high in precision, equipped with a lifting platform and free replacement platform, which can be widely used in various materials and profiles. That is a good choice laser cutting machine for this Industry.

(3) Acrylic sheet: Most laser engraving machines can be used to cut acrylic sheet, but it is recommended to use a dedicated laser cutting machine. Because the best laser cutters are optimized for laser cutting, they have excellent cutting results. Usually: 60W laser engraving machine can cut 8-10mm acrylic. 80w laser engraving machine can cut 8-15mm acrylic.

(4) Leather products: Choose a suitable laser engraving machine, which has a fast cutting speed and is equipped with a honeycomb cutting platform. Choosing the best laser cutting machine equipped with a honeycomb cutting platform is a good choice. which has the advantages of fast cutting speed, high cutting precision and high product quality.

4. Laser engraving speed:

Compare the working speed of the incoming machine. On the premise of excellent engraving effect, please pay attention to the working speed of the machine. Only when you produce more products in a short period of time, you can create higher profits.

5.Machine accuracy:

The biggest difference between laser engraving machine and traditional engraving equipment/hand engraving is the engraving accuracy. For fine projects/drawings, the requirements for engraving accuracy are relatively high. If you want to produce high-precision products, then please choose the high accuracy best laser cutter.

6. Machine quality:

The best laser cutting machine parts are more identical in appearance and have quite different laser engraving machine parts and further different qualities, such as:

1:Stepping motor of the best laser cutter: It will affect the engraving accuracy of the cnc laser engraving machine. Different types of stepping motors, imported motors, domestic motors, high-quality motors and low-quality motors can be used.

2:Laser lens of the best affordable laser cutter: Affecting the power of laser engraving machine, it can be divided into imported lens, domestic lens, and domestic lens can be divided into imported material and domestic material. The price difference is very big, the working effect and service life are also the same.

3:Laser tube of the best laser cutters machine: the heart of laser engraving machine. Imported laser tubes are expensive, generally tens of thousands of yuan. Most household laser engraving machines use household laser tubes, which are used by most laser engraving machines. The quality of household laser tubes is quite large.

4:Machine tool of the best laser cutting machine: When choosing a machine tool, pay special attention to the quality of the machine tool, especially the thickness and strength of the structure.

7. Accessories and consumables:

Optical isolator, xenon lamp, mechanical console, water-cooled equipment, optical equipment (half mirror, total mirror, refractor, etc.) and other accessories are also one of the important factors affecting the overall price of laser cutting machine, so choose high -quality accessories It often costs too much, but it can make the equipment run smoothly and can get twice the processing speed. If you are in a small industry, then you can choose the affordable laser cutter. If it is a large industry, I think high-quality accessories are very important for the best laser cutter.

We introduced 7 factors that we need to consider. It is a buyer need to know how to choose the best laser cutter machine.All the 7 factors will affect your choice,so we must conside this factors before we decide to buy the affordable laser cutter.

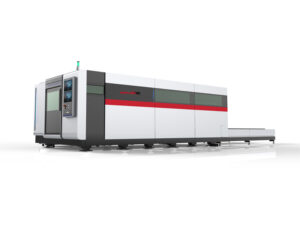

BuyCNC Best Laser Cutter For Sale

BuyCNC Laser Equipment Co., Ltd. is a manufacturer specializing in the production of best laser cutters. We have a variety of affordable laser cutters for customers to choose from. Laser cutting machines with cutting power from 1000w to 8000w can be produced. Our factory is independent and independent from the machine tool welding of fiber laser cutting machine, gantry machining center, finishing milling, spraying, and assembly. It has strict quality control procedures and quality assurance. The machine tool is annealed to stress-relief treatment, which has a long service life and low machine failure rate.

BuyCNC 12000w Fiber Laser Cutting Machine Shipped Successfully

BuyCNC

Laser Cutter For Metal Signs Help Advertising Industry

Laser

Why Choose China Fiber Laser Cutting Machine Manufacturer

Why

Fiber Pipe Laser Cutter Is Popular In Door And Window Industry

Table