laser welding aluminum

Video

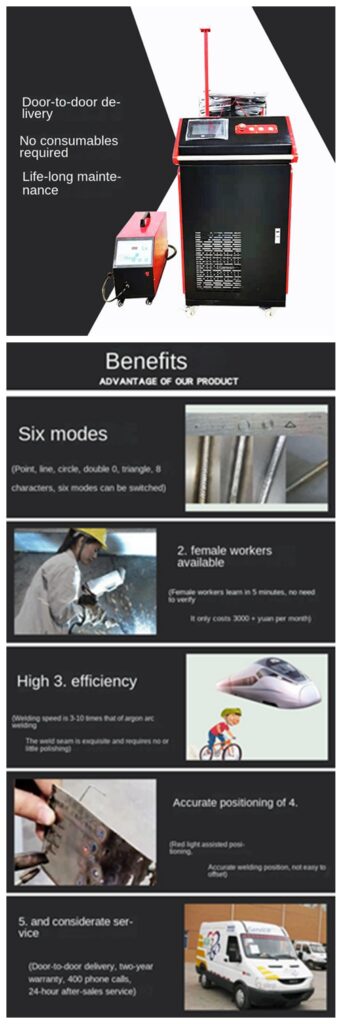

Introduction of Laser Welder Machine

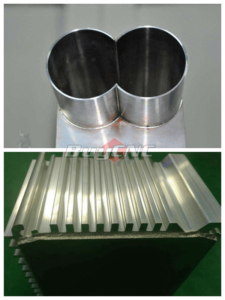

The aluminum and aluminum alloys in the laser welding aluminum machine have the characteristics of low density, relatively high strength, good wear resistance, electrical conductivity, thermal conductivity, and good mechanical properties at low temperatures. The aluminum laser welding machine is widely used. Used in aerospace, automotive, electrical, chemical, transportation, defense and other industrial sectors.

The chemical activity of aluminum and its alloys is very strong, and it is easy to form a refractory oxide film on the surface. In addition, aluminum and its alloys have strong thermal conductivity, and it is easy to cause non-fusion phenomenon during welding of laser weld aluminum.

Because the density of oxide film is close to that of aluminum alloy, it is also easy to become inclusions of weld metal. Compared with tungsten tungsten arc welding or fusion argon arc welding, laser welding of aluminum alloys is fast, narrow weld seam, small thermal strain, reduced lap joints, and can greatly reduce weight. So aluminum laser welder is popular.

Advantages of aluminum laser welding machine:

Application advantages of laser welding aluminum in aluminum alloy products:

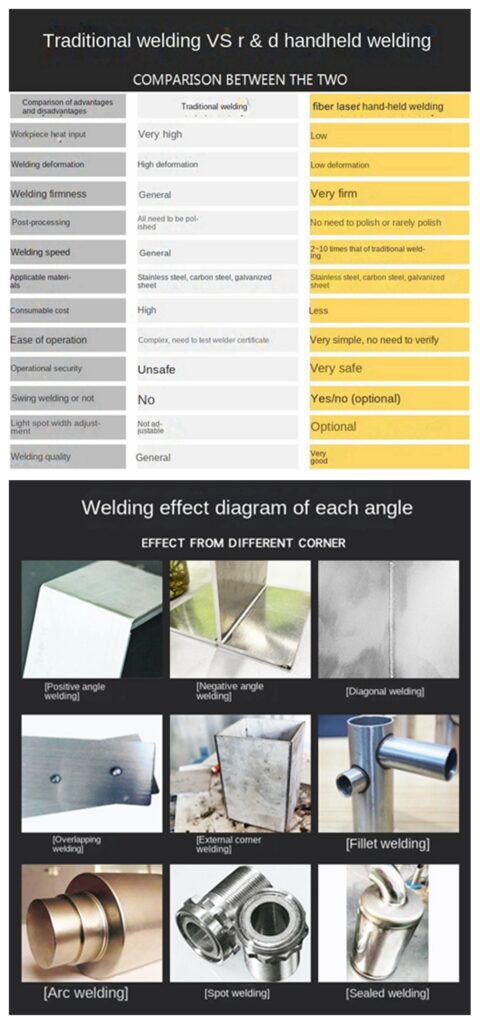

1. High energy density, low heat input, small thermal deformation, narrow melting zone and heat-affected zone, and large melting depth.

2. The cooling rate is high, the weld structure is small, and the joint performance is good.

3. Compared with traditional welding, laser welding does not use electrodes, which reduces labor and cost.

4. No vacuum atmosphere is required during electron beam welding, and protective gas and protective pressure can be selected. The shape of the weldment is not affected by electromagnetics and does not generate x-rays.

5. It can weld metal materials inside closed transparent objects.

6. The laser can be transmitted over a long distance through the optical fiber, and the process adaptability is good. With the cooperation of the computer and the manipulator, the automation and precision control of the welding process can be realized.

Applications of aluminum laser welder:

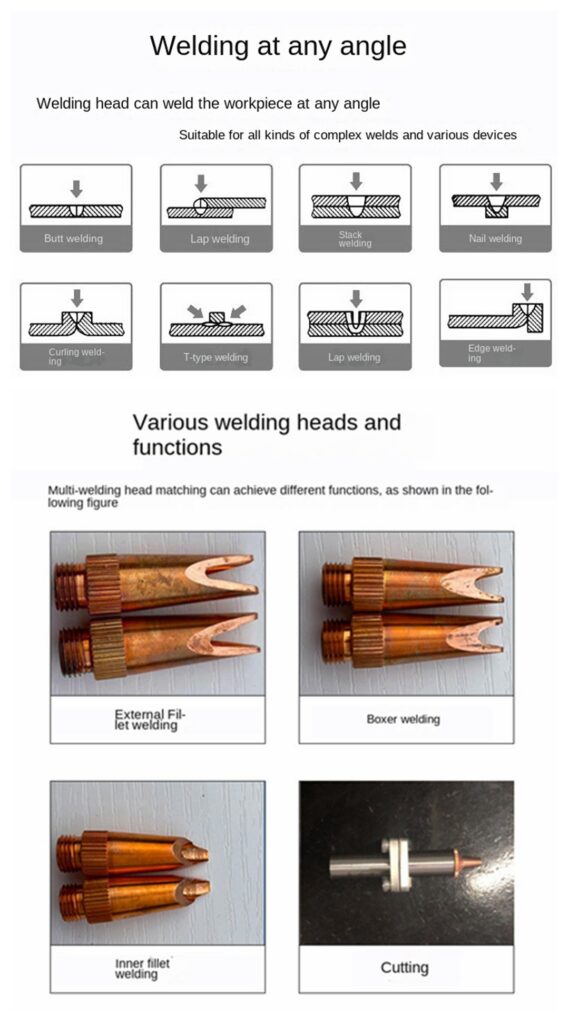

In the processing industry of laser welding aluminum, it is widely used in the automotive industry. The auto parts use tailor welding, stitch welding, body welding and parts welding methods, while laser welding can be flexibly welded, and the welds of the welded products are firm and beautiful. In addition to the welding of automotive thin-plate structural parts, laser welding can also be seen in automotive parts, such as: engine cylinder gaskets, hydraulic tappet seal welding, automotive high-voltage relays, filters, torque sensors, turbochargers, Oil rails, cylinder head gaskets, spark plugs, block motor stators, seat adjustment screws, airbags, etc. are used in many aspects.

Aluminum laser welder machines are also widely used in aviation, machinery manufacturing, hardware, building materials, and other industries; in terms of materials, laser welding machines can be used to weld various metal plates of the same material, such as aluminum plates, iron plates, stainless steel plates, and copper plates. And aluminum copper, stainless steel copper, and other materials mixed welding. It covers areas far beyond traditional welding methods.

FAQ

1.Q: Why should we choose BuyCNC ?

A: If you choose us, you will get top quality, best service, reasonable price, and reliable warranty.

2. Q: How can I get some samples?

A: We are honored to offer you samples.

3.Q: How does your factory do regarding quality control?

A: Quality is a priority. JQ people always attach great importance to quality control from the very beginning to the very end Our products have gained CE authentication.

4.Q: How about your after-sales service?

A: We offer professional and timely after-sale 24 hours online service via phone, Skype, or TeamViewer. Our technicians will contact you once you got the machine and we could provide secure teaching as a professional factory

5. Q: If some problems happen to this machine, what should I do?

A: We provide two years machine warranty. During the two-year warranty, in case of any problem with the machine, we will provide theparts free of charge (except for artificial damage). After the warranty, we still provide a whole life time service. So any doubts, just let us know, and we will give you solutions

6. Q: Can you arrange the shipment for us?

A: Of course. We can arrange the shipment for our clients accordingly by sea and air. Trading terms FOB, CIF, CFR are available.

Related articles

Advantages Of Laser Welder for Aluminum in Various Applications

Table

Future Of Laser Steel Welding Machine and Laser Welder Aluminum

Table

Want to Get the Laser Welder Machine Price?Get Free Consultation Now!!!

Reviews

There are no reviews yet.