Stainless Steel Laser Cutter For Sale

Table of Contents

What is The Stainless Steel Laser Cutter

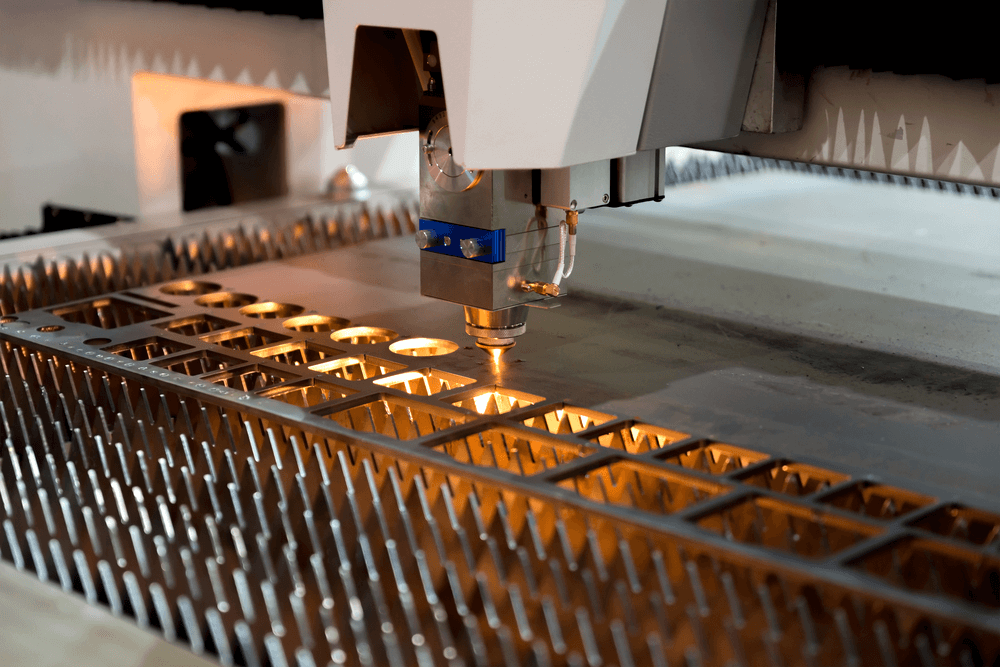

Laser stainless steel cutter is a kind of metal cutting machine, and its main cutting material is stainless steel. Due to the material characteristics of stainless steel, the YAG gem bar laser tube is most suitable. The absorption effect of stainless steel on this laser is very good.

Nowadays, the metal laser stainless steel cutter has been widely used in the field of sheet metal processing. It can cut carbon steel, aluminum, stainless steel, non-ferrous metals, etc. quickly and efficiently. It is a necessary condition for major metal processing manufacturers to build modern smart factories. The Stainless steel should be one of the materials that this cutting machine cuts the most. For metal products mainly made of stainless steel, using a laser stainless steel cutter to cut stainless steel is the fastest and most efficient processing method. However, for customers with high output of cutting stainless steel, if they want to ensure the processing quality, they must strictly control the process parameters of the stainless steel cutter before the equipment is started.

A good stainless steel cutting machine has outstanding performance in cutting stainless steel. The laser beam output is of high quality, high power density, and very good absorption of metal materials. In the plane cutting machine series products on the market, the power is usually from 500W to 30000W to achieve full coverage.

This kind of laser stainless steel cutter has a high photoelectric conversion rate, and the conversion efficiency can reach more than 30%. The output wavelength of the fiber laser is 1.064μm, which is 10% of the wavelength of the CO2 laser. For stainless steel, the cutting speed and thickness can reach high power. The CO2 laser cutting machine is comparable to it. The accuracy of the bed of the cutting machine can meet the requirements of most stainless steel plates of different sizes. Usually, the progress of the bed is set at about 20μm-100μm. This also controls the cost of the equipment bed and allows customers to purchase cost-effective The highest laser stainless steel cutter.

The stainless steel laser cutter is convenient for cutting stainless steel and has many advantages. The purchase of a suitable laser cutting machine can effectively accelerate the development of the enterprise, save manpower, material resources and financial resources for the enterprise, and truly enable the enterprise to achieve reductions. This increase in efficiency.

Common Problem of Laser Stainless Steel Cutter

In the sheet metal processing industry, fiber laser stainless steel cutter has been widely used. When fiber laser stainless steel cutting machine is used to cut stainless steel and other metals, the laser beam irradiates the metal surface to melt it, and the molten metal is melted by gas. Blow away, so as to achieve the purpose of cutting.

For products with stainless steel as the main component, laser cutting stainless steel is a fast and effective processing method. However, when the fiber laser cutting machine cuts stainless steel, some problems will occur in the length of time, which affects the cutting quality. In fact, these problems can be solved very well. During the processing, if the process parameters of the stainless steel laser cutter are strictly controlled, the processing quality of the stainless steel workpiece can be well guaranteed.

1. If during the processing of the stainless steel laser cutter, small burrs in the shape of drips appear, I must first find out the cause, usually the main reason is that the focus is too low or the feed rate is too high. Then, we need to make corresponding adjustments to raise the focus or reduce the feed rate.

2. If during the processing of the laser stainless steel cutter, irregular filamentous burrs appear on both sides of the cut, and the surface of the stainless steel plate will become discolored. There are usually four main reasons:1. The feed rate is too low, 2. The focus is too high, 3. The air pressure is too low; 4. The material is too hot. Then, we need to make corresponding adjustments: increase the feed rate, reduce the processing focus, increase the air pressure, and equip the cooling series to cool the material.

3. If there are irregular burrs on only one side of the cutting edge during laser cutting stainless steel machine processing, there are usually four main reasons:1. The nozzle is not centered, 2. The focus is too high, 3. The air pressure is too low, 4. The speed is too low. Then, we need to make corresponding adjustments to center the nozzle, reduce the focus, and increase the processing speed.

4. If the cut stainless steel material is discharged from above during the processing of the stainless steel cutting machine, there are usually three main reasons: 1.The power is too low, 2. The feed rate is too large, 3. The air pressure is too high. Then, we need to press the stop button immediately to prevent the slag from splashing on the focusing lens of the cutting machine, and we need to increase the power, reduce the feed rate, and reduce the air pressure.

In the process of stainless steel cutter cutting stainless steel, we will also encounter other problems, for example, the problem of yellow cutting edge, the main reason may be that the nitrogen used by the cutting machine is impure and contains oxygen impurities. Then, we need to change the gas and use good quality and high purity nitrogen.

Laser Stainless Steel Cutter Working Principle

The laser cutting machine for stainless steel sheet also occupies a large proportion in industrial production. The main area of stainless steel and low-carbon copper is the difference in their composition, and the cutting mechanism is also different. Stainless steel contains 1% to 20% chromium deposits tend to destroy the oxidation process.

When the stainless steel cutting machine is cutting, the iron in the stainless steel will all react exothermicly with oxygen. The oxidation of chromium has the characteristic of preventing oxygen from entering the inside of the molten material, so that the amount of oxygen entering the molten layer is reduced, and the molten layer is not completely oxidized. Reduce, so that the cutting speed is reduced. Compared with low-carbon steel, stainless steel cutting requires higher laser power and oxygen pressure. Although stainless steel cutting achieves a more satisfactory cutting effect, it is difficult to obtain a completely slag-free kerf. Using inert gas as auxiliary gas to cut stainless steel can obtain non-oxidized trimming, which can be directly used for welding, but its cutting speed will be reduced by about 10% compared with oxygen as auxiliary gas.

The most important process parameters that affect the cutting quality of a stainless steel laser cutting machine are cutting speed, laser power, oxygen pressure and focus, respectively, which represent the influence of laser power, cutting speed and oxygen pressure on the cutting quality of 2mm thick stainless steel.

Application Of Laser Stainless Steel Cutting Machine

The cutting effect of stainless steel laser cutter is better than other cutting machines, faster and clearer. Compared with the traditional oxyacetylene, plasma and other cutting processes, the advantages of laser cutting speed, narrow kerf, small heat-affected zone, good verticality of the kerf edge, and smooth cutting edge make its application more and more widely. Here is a summary of the five major industries where stainless steel laser cutter is mainly used.

1. Sheet metal processing: Simply put, it is to use a stainless steel laser cutter to process a variety of plates and cut a variety of different graphic parts.

2. Automobile industry: Many corners and corners of the automobile industry, such as car doors, car exhaust pipes, etc., need to be processed after forming. If manual labor is used, not only the accuracy is difficult to achieve, but the efficiency is also very low. The use of stainless steel cutter can quickly batch processing.

3. Decoration industry: Because of the laser stainless steel cutter’s fast speed, flexible and convenient cutting, many complex graphics can be formed quickly, which is deeply loved by decoration companies. As long as it is what the customer wants, after the drawing is made through CAD, etc., it can be directly cut out with related materials, and there is no problem in customization.

4. Advertising industry: The advertising industry has a lot of customization and traditional methods are very inefficient. Laser stainless steel cutter is very suitable for this industry. No matter what kind of word, no matter how many different companies, it can be quickly cut out.

5. Kitchenware industry: Now there are more and more houses, more and more decorations, and the demand for kitchenware-related products is increasing. The laser stainless steel cutting machine is very suitable for cutting thin stainless steel, with high speed, high precision, good effect, and can The realization of customized and personalized product development is deeply loved by kitchenware manufacturers.

BuyCNC Laser is an enterprise specializing in the manufacture of laser stainless steel cutter machines, and a high-tech enterprise integrating R&D, production and sales of complete sets of laser equipment. The products are mainly concentrated in the fields of laser cutting and laser welding. BuyCNC laser also provides personalized customization. According to the needs of customers, we can customize machine beds of different sizes, lasers of different powers, and other parts for the material, thickness, and area to be processed.

Related Blogs About Laser Cutter

Advantages Of Laser Welder for Aluminum in Various Applications

Table

Future Of Laser Steel Welding Machine and Laser Welder Aluminum

Table

Advantages Of Laser Hybrid Welding and Laser Micro Welder

Table

Guide Of Laser Handheld Welder and Laser Deposition Welding

Table

Laser Aluminum Welding Is Benefits of Using Laser Beam Welding Tools

Table