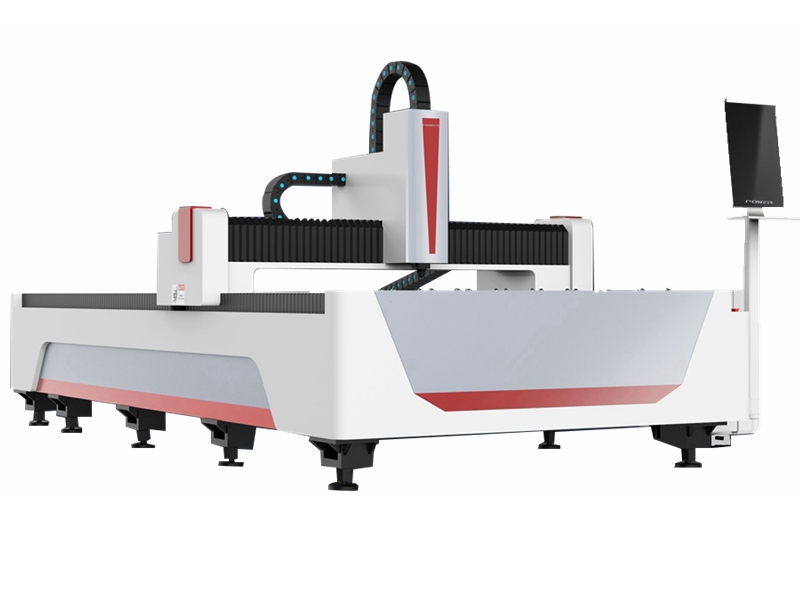

CNC Laser Cutting Machine For Sale

Table of CNC Laser Cutter Machine

CNC Laser Cutting Machine in Metal Processing

According to scientific research on data and information related to industrial production and processing technology, as a key cutting technology processing technology in the laser processing and manufacturing industry, the best CNC laser cutting machine accounts for 70% of the total, which shows that its use is widespread And key. Laser cutting technology is a more critical part of laser processing technology, and it is one of the more cutting processing technologies recognized worldwide. With the rapid development of social development and manufacturing and the continuous development of industrial production and processing technology, laser cutting technology is also following the rapid development trend and development, and its application in sheet metal processing is becoming more and more common, and it is fully utilized. Other processing techniques have incomparable effects.

Best CNC Laser Cutting Machine Principle

1. CNC laser sheet metal cutting machines: It can be universally and widely used for cutting general thick steel plates, hard alloy knives, stainless steel plates and many other metal material characteristic raw materials, as well as porcelain (raw materials: mining enterprises), laminated glass, plywood, etc. Non-metallic materials characteristic chemical substances. The management system of CNC sheet metal cutting machine is divided into three key parts: CNC lathe server, laser generator and its automatic control system.

As a part of the nerve of the entire management system, the person in charge of the automatic control system and Harmony In all normal work of all system software, its key daily tasks depend on Harmony and manipulation of the processing motion trajectory, manipulation of the focus position, and also pay attention to the machine, The overall coordination of light and electricity.

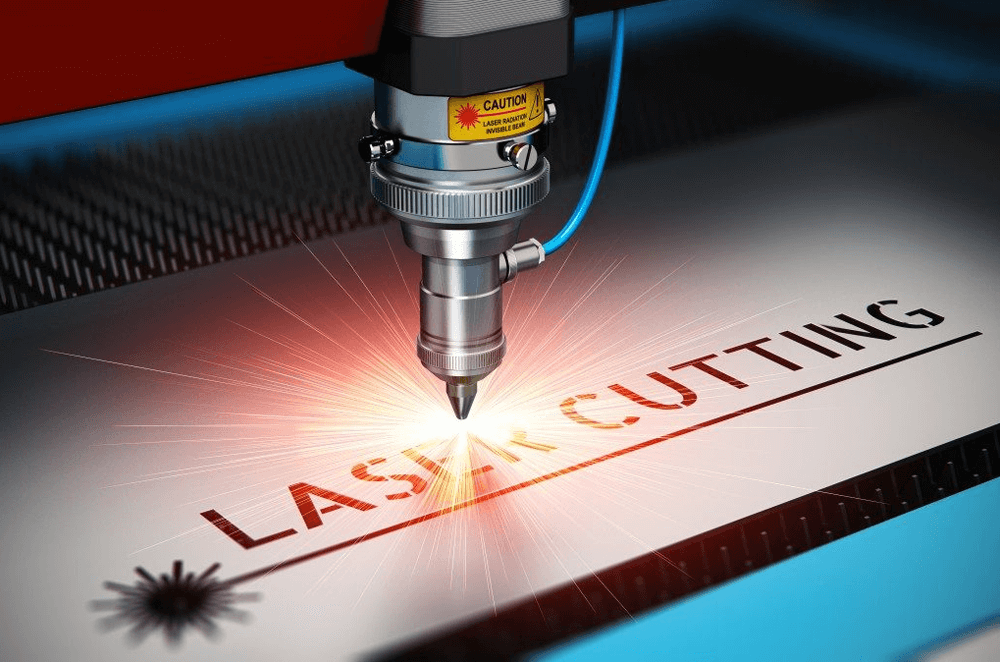

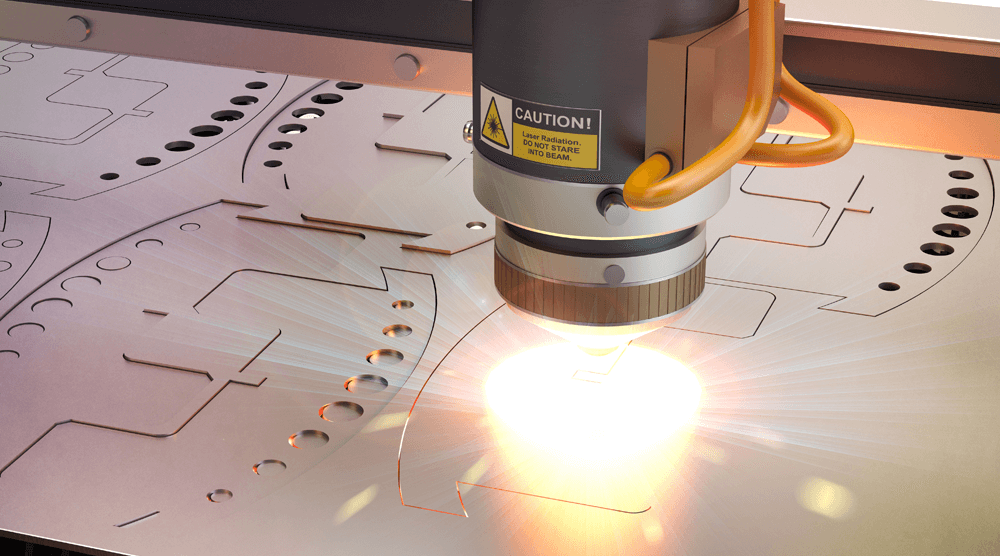

2. The basic principle of CNC laser cutting: the particle beam after the focus point can generate tens of thousands of degrees of high temperature on any hard raw material, which promotes the melting and volatilization of the raw material in an instant, and also causes a strong shock wave to achieve The molten chemicals can be spewed out and removed in an instant by a sexual method. Even more because of this unique feature, the laser cutting machine can focus the particle beam on a certain point on the surface of the raw material to be processed, causing and promoting the transformation of the laser from focusing to energy.

In addition, the distance between the two is slightly shorter. Within time, the temperature of the particle beam concentration point rapidly rises to the melting point of the raw material, and then rises to the melting point, so that the raw material is vaporized, and then a small circular hole is produced. On the other hand, under the manipulation and actual operation of the laser cutting machine, the particle beam transforms according to its preset relative path. In the whole process, the surface layer of the raw material to be processed continuously produces vaporization and vaporization conditions, and a thin and long slit is left along the path of the laser.

Advantages of CNC Laser Metal Cutting Machines

The CNC metal cutting machines have a fast cutting rate, small slits, a part of the wound is clean and tidy, and the overall cutting quality is good. Compared with traditional cutting technology, laser cutting technology will not cause serious damage to the CNC blade; the heat generation of the cutting surface is less harmful. The application range of cutting is very large, and it will not be limited by the appearance and other levels. Keep CNC machine tools.z In the case of complex processing, you can perform various sheet metal processing tasks without relying on the application of abrasive tools and still maintain high quality and high precision. Therefore, many industrial production and manufacturing companies have just begun to care about the key effects of laser cutting technology, and slowly and proactively use laser cutting technology in sheet metal processing.

Development of CNC Laser Metal Cutting Machine

In my country’s industrial production and processing management system, CNC laser sheet metal cutting machine is mainly used in cutting, electric welding, marking and quenching and tempering processing. Although the development of laser cutting industry in my country is still not later than that of European and American countries, because of its basic weakness, CNC laser sheet metal cutting machine cannot maintain its universal application, and the overall development trend level of laser processing industry production is consistent with There are still big differences between countries. Laser cutting technology is a kind of processing technology that started and used many times in the laser processing industry. Its storage, application and marketing promotion all have a large development and design indoor space. With the rapid development trend of economic development technology in our country and the continuous development of industrial production industries, more and more sheet metal processing industries must develop and design, and a large number of industrial production cities will use more and more CNC metal cutting machines.

Specific Application of CNC Sheet Metal Cutting Machine

1. CNC Laser cutting can reasonably use the advantages of CNC programming software, greatly increase the utilization rate of metal sheet-type raw materials, reduce the application of raw materials and extravagant waste, and ease the labor efficiency and scope of employees to achieve ideal practical effects. On the other hand, The CNC sheet metal cutting machine can improve the versatility of cutting, save the cutting stage of sheet metal cutting, reasonably reduce the clamping of raw materials, and reduce the time of processing assistance.Therefore, it promotes the more effective distribution of cutting plan and reasonable increase of processing rate and raw material saving.

2. With the steady development of CNC laser machine sales market, the speed of machine research and development represents competitiveness. Because of the use of CNC metal cutting machines, it can reasonably reduce the total number of applications of abrasive tools, save the development progress of new products, and promote the speed of its development and design. The quality of the parts after laser cutting is excellent, and the productivity is obviously increased, which is conducive to mass production manufacturing. It strongly ensures the sales market atmosphere of declining product development progress, and the use of laser cutting can carry out the specifications and dimensions of the blanking mold. The precise positioning of the company lays a solid foundation for mass production in the future.

3. In the sheet metal processing work, basically all the parts must be formed on the CNC laser sheet cutting machine at one time, and the immediate electric welding welding is carried out. Therefore, the use of the laser cutting machine reduces the process flow and construction period, which is reasonable The increase rate can maintain the two-way improvement and reduction of employee labor efficiency and processing costs, and promote the improvement of the office environment, greatly improve the speed of product development, reduce the capital investment of abrasive tools, and reasonably control costs.

4. CNC laser metal cutting machines are widely used in sheet metal processing, which can reasonably reduce the processing and manufacturing cycle time of new products, etc., greatly reduce the capital investment of abrasive tools, etc., greatly improve the processing speed of employees, and save Eliminate redundant processing procedures. In addition, the universal use of CNC laser sheet metal cutting machine in industrial production and processing can reasonably process a variety of complicated parts and improve accuracy, which is beneficial to immediately reduce the processing cycle time, increase the processing speed, and reasonably increase labor efficiency.

How to Choose Best CNC Laser Cutting Machine

When you are going to buy an advanced CNC sheet metal cutting machine, because the CNC laser metal cutter is a high-tech CNC machine. Because it is more expensive, and the performance is relatively large due to the difference in machine parts, so we need Choose the most suitable CNC laser cutting machine. Next, I will recommend three points that you need to pay attention to when you buy a CNC laser cutting machine.

1. Let the CNC laser sheet metal cutting machine manufacturer provide you with an example next to you, and give the contact number of the staff who purchased it at that time;

2.let the CNC laser sheet metal cutting machine manufacturer provide photos and warehousing logistics photos during the manufacturing process of the CNC laser cutting machine.

3.let CNC laser sheet metal cutting machine manufacturers provide freight logistics delivery photos.

BuyCNC is the leading CNC laser sheet metal cutting machine in China, we have a variety of CNC laser cutting machines. Power from 1000w to 3000w can be for your choice, we will also provide you with the most affordable price and the best quality pre-sales and After-sales service.

BuyCNC 12000w Fiber Laser Cutting Machine Shipped Successfully

BuyCNC

Laser Cutter For Metal Signs Help Advertising Industry

Laser

Why Choose China Fiber Laser Cutting Machine Manufacturer

Why

Fiber Pipe Laser Cutter Is Popular In Door And Window Industry

Table