CNC Router Aluminum Guides

Are you looking for CNC router for aluminum processing, then please check this guide about CNC router aluminum. It will help you choose the best CNC router for aluminum, I hope it can solve your troubles.

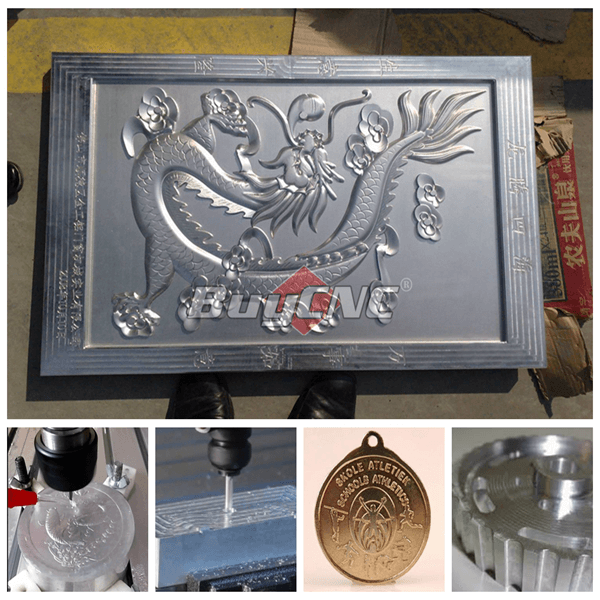

Aluminum (Aluminum) is a soft metal that can be engraved into characters and patterns by a CNC router machine, and it can also be cut into different shapes. There are many advantages to using a CNC router aluminum machine to process aluminum because this metal is light in weight and very strong. . Airplanes, railways and even F1 cars use aluminum. When we are preparing to process aluminum, most people will only think of using a professional large-scale high-end milling machine. This kind of machine can complete very complex tasks, but for soft metals such as aluminum, the CNC router machine can also be perfect Realize the processing of aluminum.Compared with other processing methods, it can minimize material waste and reduce errors. These machines have many configurations, from small DIY desktop CNC aluminum milling cutters to industrial equipment used in manufacturing plants.

Can CNC Router Cut Aluminum

Now almost all CNC router machines are equipped with advanced spindles, which can perfectly process soft metals such as aluminum. As long as the correct feed rate is set and the appropriate CNC router kit is selected, then a series of aluminum processing can be carried out. When we cut aluminum, it should be noted that aluminum is different from plastic and wood, because aluminum is a soft metal, it has a smaller optimal position, which can increase the speed and optimize the feed. If you leave the best position and wear quickly, the tool will start to break. The resulting surface finish is poor. Moreover, the material of aluminum has many viscosity factors. When we cut aluminum, it tends to stick to the knife. When these deposits are deposited too much, the service life of the tool will be greatly reduced, especially when we run it at a speed of 20,000RPM or higher, the tool will be more easily damaged, so we must remember to clean or replace the tool at all times.

How to Cut Aluminum with CNC Router

When we are ready to use CNC router Aluminum machine to process aluminum, we have to do the following important steps to successfully cut aluminum.

1. Fix the material

Even though aluminum is a soft metal, it is still a metal material, which is different from wood and plastic. The hardness of this material can cause parts, tools and machines to rattle under tremendous pressure, and it is easy to damage the CNC router if it is not handled properly. When we process, a lot of friction and stress will be generated on the cutting spindle and the gantry of the fixed milling machine. Every part of the machine will be under tremendous pressure. You must secure the material in the strictest way.

Tips of fix material by CNC router Aluminum:

1.Use the shortest possible tool-the cutting surface of the tool only needs to be slightly longer than the deepest cutting length. We need to avoid using longer tools because they are easier to bend than shorter tools.

2.Make tiny cuts-because your CNC milling machine is not designed for cutting metal, it is best to limit the cutting depth to 0.005 inches to 0.010 inches (.125mm to .250mm). If your machine is strong enough, you can choose a higher feed speed at these small cuts.

3.Increase the strength of the CNC router. You may be able to use a larger router planer, increase the size of the bearing, add some support, and perform other operations. You want to make improvements to help reduce the amount of bending of the machine.

2. Keep it lubricated

When we are cutting aluminum, one thing to keep in mind is that aluminum has many viscosity factors, and we need to keep the tool to cut aluminum normally. Then we need lubricating oil or oil mist cooling system.

Installing an oil mist cooling system is one of the easiest ways to keep materials and tools cool, which can improve machining quality and extend tool life.

If you don’t want to invest in an oil mist system, you can always spray some WD-40 on the cutting machine regularly. Many industrial cutting fluids are environmentally friendly and specially designed for CNC machining. Finally, if you have a bunch of WD-40 or other thin oil tanks, it should work fine. You can even use a brush to lubricate the tool path from time to time. Just make sure you don’t wrap the bristles in the rotating tool.

Although cutting wax is another excellent choice, in some cases it works better than other methods. The advantage is that you can rub it to the surface of the material to be cut and it will not be blown away. However, each time you pass a new depth, you must apply more wax.

Cutting wax is very suitable for cutting thin metal sheets or for high-speed engraving. If you want to process the material in depth, the cutting oil and oil mist cooling system will still be a better choice.

3.Choosing the right milling cutter

When CNC router aluminum is processing aluminum, we should use an end mill, which is made of cemented carbide or HSS (high speed steel). The end mill has the advantages of high precision and not easy to break. End mills have a variety of styles, sizes and chip flutes, including single-edged carbide end mills and double-edged carbide end mills. Generally, the more flutes, the better the quality.

Unlike large industrial machines, The CNC router aluminum machine does not have enough rigidity or a large enough frame to use larger cutting tools. You will only be able to use small end mills and milling cutters.

How to Choose the Right Cutting Tool for Aluminum

Leave enough space to remove metal shavings-aluminum is very soft, so it tends to stick to cutting tools. Make sure there is enough space between the cutting grooves to lift the metal from the part and the cutting blade.

Use hardened and coated cutting tools-aluminum is not a hard metal, but aluminum can still easily break a small cutting tool. You should choose an end mill with at least two flutes.

Choose a smooth and sharp tool-as mentioned earlier, aluminum likes to stick to the surface of the cutting tool. When cutting aluminum with a CNC milling machine, always use a new milling cutter or end mill.

Never use plastic cutting tools with aluminum-plastic cutters move the chips to the side or push them down towards the material. When cutting aluminum, always use an end mill with a chip flute to lift the chips up and out of the cutting path.

In most cases, when using CNC milling cutters to cut aluminum, you will only be able to use 1/8″-1/4″ end mills. Most CNC milling machines have small tool spindles with light bearings and gantry frames, and you will have to make multiple cuts to reduce friction and wear.

If your CNC router aluminum machine is a large machine, the 1/4″ end mill should work properly. For smaller machines, it is best to use 3/16″ or 1/8″ tools. Remember, the larger The cutting tools require slower RPM.

| 1/4″ carbide endmill | 24,000 RPM max, 16,000 RPM ideal |

| 3/16″ carbide endmill | 32,000 RPM max, 21,000 RPM ideal |

| 1/8″ carbide endmill | 48,000 RPM max, 32,000 RPM ideal |

| 1/16″ carbide endmill | 96,000 RPM max, 64,000 RPM ideal |

Now it’s pretty unlikely that you have a 96,000 RPM machine, but this should give you an idea of how cutter diameter affects RPM. If your minimum speed is 30k RPM, then you might want to shy away from 1/4″ endmills for aluminum in favor of something 3/16″ or 1/8″.

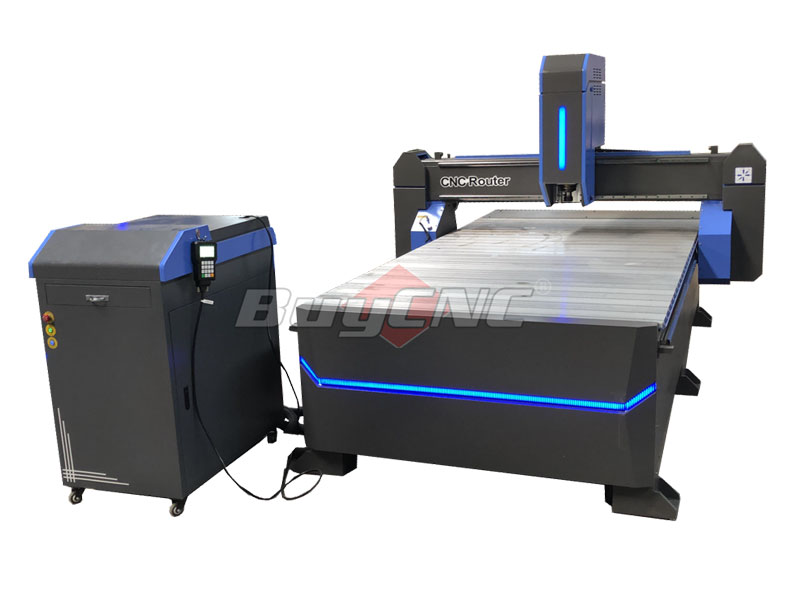

Some Best CNC Router For Aluminum

BuyCNC has a variety of CNC router machines. How to choose the best CNC router for Aluminum depends on your needs.

CNC Router Aluminum Machine Technical Parameters

| Brand | BuyCNC |

| Table Sizes | 2’x3′,4’x4′,4’x8′,5’x10′ |

| Functions | Cutting,Carving,Engraving,Millling,Turning,Drilling |

| Capability | 2D Machining,2.5D Machining,3D Machining |

| Axis | 3 axis,4th axis,4 axis,5 axis |

If you are going to use CNC router Aluminum machine for simple small-size aluminum processing, then we suggest you choose a small CNC router aluminum. Such as the desktop CNC router machine or hobby CNC router machine. This small CNC router aluminum It is very popular in the aluminum processing industry because of its low price, space saving and high processing accuracy. This is the best CNC router aluminum machine for processing small aluminum materials.

This is a beautiful and powerful aluminum CNC machine.It is also equipped with a variety of advanced equipment such as water tank and oil mist coolant system. At the same time, you can also choose a variety of The size of the working table, now we are showing a 400*400 version.

If you need to use CNC router aluminum to carry out some 3D engraving of aluminum, then you can choose the 4 axis CNC router machine which has the fourth axis of rotation. This desktop 4 axis CNC router aluminum is a good choice. It can help you make it 3D cylindrical aluminum.

This desktop 4 axis CNC milling machine is very Popular in Aluminum Industry.It has a rotary axis. This machine can process 3D aluminum, and its engraving accuracy is also very high, so it can make exquisite aluminum crafts for you.

If you are a practitioner specializing in large-scale aluminum industry, such as aluminum sheet, aluminum engraving, aluminum sheet cutting and other industries. Then we can provide you with professional large CNC router aluminum machine, such as 4×8 CNC router, 5×10 CNC router, etc. This kind of machine is very suitable for processing large aluminum materials.

As a professional woodworking CNC router with vacuum table machine, this machine body is welded by thick steel pipes, so it is enough strong to process different materials. And it has many advanced kit such as Hiwin linear rails and bearings, Germany precision helical racks on the X and Y axes etc. It is worth mentioning that the powerful CNC vacuum pump of the CNC router for sale machine can vacuum the material within 3 seconds. This greatly improves the work efficiency of woodworking CNC router machine.

If you still don’t know which CNC router Aluminum machine to choose, please inform us of the material you want to process and the industry you are engaged in. We will have professional engineers recommend the best CNC router for Aluminum for you. , We promise to provide you with the most affordable Aluminum CNC router and the best quality service.