Fiber Laser Cutting Machine Price

Table of Contents

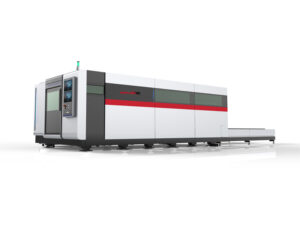

Nowadays, laser cutting machines are widely used in the automobile industry, advertising industry, kitchenware industry, sheet metal processing, cabinet industry, fitness equipment and other industries. Metal laser cutting machines are now the main equipment in the mechanical processing industry, and metal laser cutting machines are generally required. Of companies will use laser cutting machines.

As one of the most representative intelligent processing equipment in the contemporary era, laser cutting machine equipment has excellent processing effects and needs to be used in many fields. Often, a laser cutting machine can bring huge benefits to users. Nowadays, the price of fiber laser cutting machine on the market is different. Users often feel “dazzled” when choosing, so what factors determine the metal Laser cutting machine price, how should users choose?

Factors Affecting Fiber Laser Machine Price

1. The first factor affecting the fiber laser cutting machine price-manufacturing cost:

In order to ensure the stability and quality of a good laser cutting machine, it must be the best for the selection of components, otherwise the use of some general components will definitely not be good for the stability of the laser cutting machine, and it will also affect the brand reputation. . So why good brand machines have high stability, while some cheap machines have unsatisfactory stability. Because there is no technology competition, only prices can be compared, so the selection of components must be cheap.

2.The second factor affecting the fiber laser cutting machine price-brand of laser cutting machine:

Of course, the size of the brand determines the price of the device, which is a relatively abstract concept. We can understand it in this way. Big brands are much more secure than small factories in terms of equipment quality, equipment parts, equipment performance, and technology, including after-sales service. These are all added value of the product, which is also laser cutting. A general rule of the machine market, so the price of the laser cutting machine of the big brand will be higher than that of the small brand.

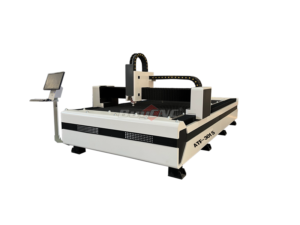

3.The third factor that affects fiber laser cutting machine price-machine format:

Laser cutting machine manufacturers generally have several standard format sizes, and for the special needs of customers, they can also customize non-standard machine tools that meet customer sizes. The standard size is the specification that the manufacturer has made all the time, and the non-standard size needs to be specially customized, so the customized format is more expensive than the standard format. BuyCNC laser currently produces cutting machine formats generally in 3013, 3015, 4015, 4020, 6015, 6020, 6025, which basically cover all processing needs on the market.

4.The fourth factor affecting the sheet metal laser cutting machine price-laser brand

As we all know, lasers are the core optical components of laser cutting machines. There are different brands of laser cutting machines, and the beam quality varies greatly. The price of lasers also varies with the brand. There are huge differences. For example, BuyCNC lasers use Raycus lasers and IPG lasers, while domestic lasers are relatively cheaper than imported ones. At present, imported lasers are superior to domestic lasers in terms of stability and beam quality. The laser can be selected by the customer.

5. The fifth factor that affects the price of metal laser cutting machine-key components:

Other key components of the fiber laser metal cutting machine such as guide rails, rack and pinion, servo motors, etc., their brand and quality also lead to low prices. One reason. Therefore, BuyCNC Laser reminds users that when buying a laser cutting machine, they must pay attention to the specific configuration, and do not blindly be tempted by low prices. The key parts and components of BuyCNC laser cutting machine adopt industry-leading brands, and the quality is guaranteed. trustworthy.

6. The sixth factor that affects the price of sheet metal laser cutting machine-power:

The manufacturers of the same brand, the higher the equipment power, the higher the price. Therefore, before making an inquiry, you must be clear about the material and thickness you want to cut, as well as your own requirements for cutting speed and capacity. At present, the power of laser equipment produced by BuyCNC Laser is 1000W-30000W, which can meet your basic processing needs.

7.The seventh factor affecting the sheet metal cutting machine price-after-sales service

The laser tube and reflective lens of the laser cutting machine are all consumables, which have a certain service life and need to be replaced after they expire. This requires the manufacturer to provide a strong after-sales service guarantee to provide these consumables in a timely manner. With these guarantees, the metal cutting machine price is bound to be higher. Manufacturers without these service guarantees will not provide buyers with these services if their products are sold. Therefore, the metal cutting machine price is very cheap. When buying a laser cutting machine, when you encounter the same model and the same type of product but at different prices, you must summarize the reasons and then purchase according to your needs. You must not only regard the laser metal cutting machine price as the only one. Reference factors should be understood from many aspects.

Some Accessories that Affect The Fiber Laser Cutting Machine Price

1. Fiber laser: It is the core component of fiber laser cutting machine, and it is also the “power” of fiber laser cutting machine to realize cutting operation. Therefore, when customers purchase fiber laser cutting machines, they must pay attention to the choice of fiber lasers. Currently, the more well-known fiber laser brands include Raycus, IPG, and Max. It is the most important component that affects the fiber laser cutter price.

2. Cutting head: The cutting head of the laser cutting machine is a laser output device, which consists of a nozzle, a focus lens and a focus tracking system. The cutting head of the laser cutting machine will travel according to the set cutting track, but the height of the laser cutting head needs to be adjusted and controlled under different materials, different thicknesses, and different cutting methods. Different cutting heads will also affect the sheet metal laser cutting machine price

3. Servo motor: Servo motor refers to the engine that controls the operation of mechanical components in the servo system, and is an auxiliary motor indirect speed change device. The servo motor can control the speed and position accuracy very accurately, and can convert the voltage signal into torque and speed to drive the control object. The high-quality servo motor can effectively ensure the cutting accuracy, positioning speed and repeat positioning accuracy of the laser cutting machine. Because servo motors are more expensive, this will also make the metal laser cutting machine price become more expensive.

4. Software system: It is commonly referred to as a numerical control system. The fiber laser cutting machines produced by general manufacturers use imported numerical control systems. However, some manufacturers are developing CUT software by themselves, but relatively few. At present, CypCut Controller is one of the most used by domestic manufacturers.

5. Water chiller: The chiller is the cooling device of the laser cutting machine, which can quickly and efficiently cool the laser, spindle and other devices. The current chillers all contain input and output control device switches, as well as advanced functions of cooling water flow, high and low temperature alarms, and their performance is more stable.

6. Air supply system: The air supply system of the fiber laser cutting machine mainly includes air, filter devices and pipelines. Among them, there are two types of gas, bottled gas and compressed air, and users can choose according to their needs.

The above are several important parts that affect the price of sheet metal laser cutting machine, because these parts are necessary for fiber laser machine, and there are certain differences in the price of these parts. Therefore, we must choose the most suitable parts for us to purchase the laser cutting machine at the most suitable price.

Conclusion of the Fiber Laser Cutting Machine Price

There are many laser cutting machine manufacturers in China, and the production technology and quality of the laser cutting machine equipment provided are also different, which also makes the fiber laser price inconsistent. Secondly, the size of power is also the fundamental factor affecting the price of sheet metal laser cutting machine. Generally speaking, the performance of high-power laser cutting machine is better in all aspects, and the required manufacturing cost is also higher, so laser cutting machine The power is different, so the big power laser metal cutting machine price is more expensive. In addition, there are many types of laser cutting machines, such as three-dimensional laser cutting machines, stainless steel laser cutting machines, round tube laser cutting machines and other equipment, each with different price points.

Generally speaking, brand awareness can easily induce customers to purchase laser cutting machines. In fact, when users choose laser cutting machines, they should combine the brand, power, and after-sales service to make a decision. An excellent manufacturer of laser cutting machines, in addition to having a good reputation, should also have more laser cutting machines with different powers for customers to choose equipment according to their own needs. In addition, considering the use of equipment, good after-sales service is also Very importantly, this will make customers feel a better product operation experience.

Jinan BuyCNC is a domestic enterprise specializing in the production and development of metal laser cutting machines, and it is a benchmark enterprise in the field of laser cutting machine production in China. After years of research, development and innovation, the laser equipment developed and produced has high electro-optical conversion efficiency, good beam quality, stable performance, and high cost performance. Many technologies are in the leading position in the same industry in China. We will also provide you with the most attractive fiber laser cutting machine price.

Related Blogs About Fiber Laser Price

BuyCNC 12000w Fiber Laser Cutting Machine Shipped Successfully

BuyCNC

Laser Cutter For Metal Signs Help Advertising Industry

Laser

Why Choose China Fiber Laser Cutting Machine Manufacturer

Why

Fiber Pipe Laser Cutter Is Popular In Door And Window Industry

Table