Table of Contents

The wooden carving CNC machine has become one of the most popular CNC machines in the woodworking industry. Because this kind of machine can process a variety of products, such as small wooden products, wooden furniture, wooden artwork and so on. And The wood carving machine has many types of machines for buyers to choose from.

And this kind of machine can be equipped with a variety of CNC milling cutters, so that the machine can achieve a variety of functions, such as engraving, cutting, grooving, lettering, drilling and so on. This wood carving machine is mainly used to process wood, but this machine can also process other materials, such as rubber, stone, resin, plastic, acrylic, foam, soft metal, etc.

Do you want to own a CNC engraving machine of your own? If you are a beginner in the CNC router industry, you don’t know how to choose the most suitable machine for you. Then please read this article carefully. We will introduce the CNC wood carving machine for sale in many aspects. And we also recommend BuyCNC’s best-selling CNC Machines.

What is the Wood CNC Carving Machine

The CNC wood carving machine is one of the most widely used machines in the woodworking industry, and it is mainly used to process wood. As a highly automated machine, it has high processing speed and engraving accuracy, which can greatly save manpower. The most important thing is that this machine can quickly complete a large number of repetitive tasks. In addition to processing wood, this CNC machine can also cut, engrave, and drill plastic, acrylic, soft metals (copper, aluminum) and other materials.

Working Principle of CNC Wood Carving Machine

The working principle of the wood carving machine is to carry out design and layout through the special engraving software configured in the computer, and the computer automatically transmits the information of the design and layout to the wood carving CNC machine controller, and then the controller converts the information into a stepping motor capable of driving Or a signal with power (pulse train) from a servo motor to control the host of the CNC wood carving machine to generate X, Y, Z three-axis engraving tool path base diameter.

The high-speed rotating engraving head on the carving machine cuts the processing material fixed on the worktable of the host machine through the tool configured according to the processing material, and can engrave various flat or three-dimensional relief graphics and characters designed in the computer. Engraving automation operations.

Motor Driver Classification of CNC Engraving Machine

1. Stepper driver + stepper motor

The stepping system is a widely used drive system, which is cheap and works well when equipped with a Lei Sai high subdivision drive. But the defects are also more obvious, such as: resonance, noise, increase in speed, decrease in torque, prone to losing steps after working for a long time, and excessive temperature rise of the motor.

2. Hybrid servo drive + motor

Hybrid servos are rarely used in China, and the price does not have a very big advantage compared to AC servos, and can only be used in some special industries.

3. AC servo drive + AC servo motor

The price of AC servo is relatively high for engraving machines. In addition, the application of AC servo has certain requirements for the structure, electrical appliances, control system, and transmission system of the machine tool.

The AC servo system has: fast response, large torque, high speed, high precision, low heat generation, continuous long-time work, complete alarm system, etc. Disadvantages: Different equipment needs different servo parameters, and the adjustment parameters require high-level technical engineers.

The Types of Wood CNC Carving Machine

1.Classification according to the transmission mode:

The woodworking carving machine can be divided into a screw drive CNC engraving machine and a rack drive CNC wood carving machine according to the transmission mode. Screw-driven CNC woodworking engraving machines, also known as advertising CNC engraving machines, are usually small in size. For example, 3018 CNC router, 6090 CNC router, 4×4 CNC router, etc.Rack drive CNC wood routers are usually large sizes, such as 4×8 CNC routers, 5×10 CNC routers, or other custom sizes. This kind of machine is generally used to process large products.

2.Classified according to processing materials:

(1).The wood carving CNC machine:

The wood carving CNC machine is a big category under the CNC router machine, which can be roughly divided into: wooden door engraving machine, furniture engraving machine, coffin engraving machine, handicraft engraving machine and wood carving engraving machine, Wooden door engraving machine is mainly used in wooden door, cabinet door, wardrobe door industry. The configuration is higher than ordinary woodworking engraving machine. Because of the problem of loading and unloading, the wood carving CNC machine is generally equipped with vacuum adsorption table.

Furniture carving machine is mainly used in European style furniture and modern furniture. The production of antique furniture and office furniture is generally equipped with multiple spindle motors in order to improve processing efficiency. The coffin engraving machine is mainly used for the production of coffins, longevity woods, and longevity materials. It is generally model 1325 with multiple spindle motors and coffins.

The competition in the wood industry is mainly the competition of the gallery, so the powerful manufacturers often lead other manufacturers in the gallery. The handicraft engraving machine can be called a relief engraving machine, generally equipped with 4-10 heads, multi-head processing, reducing Cost, improve production efficiency, the last wood carving machine is the standard configuration of the 1325 model engraving machine, its internal configuration can be selected according to the specific needs of users, generally suitable for customers in the decoration industry.

(2).Stone carving machine:

The stone carving machine is a high-tech, fully automatic computer-controlled engraving equipment that can engrave calligraphy and painting on natural stone, glass, and ceramics. It can process a variety of materials, such as marble, granite, jade, bluestone, black stone and other stones, as well as ceramics, glass, plexiglass, PVC boards, aluminum-plastic panels, bamboo and wood. Hard stone such as granite can be carved up to 5mm in layers, and marble and bluestone can be carved up to 5mm at a time. Now the stone engraving machine has been widely used in ceramic tile processing, stone processing, furniture industry and so on.

(3).Metal carving machine:

Metal CNC carving machine is mainly used to process metal. This kind of machine can process soft and hard metals. Soft metals include aluminum and copper. Hard metals include iron, steel, etc. Compared with the laser metal cutting machine, the metal CNC cutting machine is cheaper and can meet most of the needs. If you want to process metal but the budget is not enough, then the metal CNC engraving machine is a good choice.

Classification by CNC carving machine axis:

If you want to classify according to how many processing axes a CNC engraving machine has, it can be divided into 3 axis CNC carving machine, 4 axis CNC wood engraving machine, rotary axis CNC engraving machine and 5 axis CNC engraving machine.

The Component of Wood CNC Carving Machine

The structure of The wooden CNC carving machine has four main parts, namely the engraving machine tool, engraving control software, computer and electrical control cabinet, each of which plays an important role. The following will introduce their functions in detail.

1. CNC engraving machine body

This is the mechanical equipment part, including the frame, gantry, guide rail, etc., through which the engraving machining is completed. From the material, there are mainly two kinds of cast iron machine tools and cast aluminum machine tools. The price of cast iron platform is high, and the stability of the body is higher, so it is mainly used for large-scale CNC engraving machine. The cast aluminum platform is light in weight and high in strength, and is mainly used for small CNC engraving machines.

2. Engraving control software

It is used to process and interpret the NC processing codes generated by the engraving CAD/CAM software, issue processing control instructions, and direct the engraving machine to perform processing actions to complete the engraving of the product.

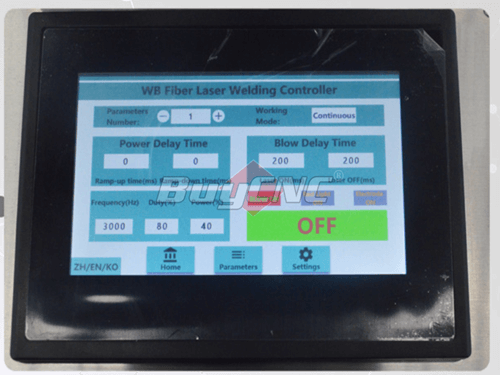

3. Computer(CNC Router Controller)

This is the operating carrier of the engraving control software, which coordinates and controls the various hardware mechanisms of the engraving machine.

4. Electrical control cabinet

The electrical components and devices of the wooden carving CNC machine are all connected by wires. This is the signal detection part of the drive of the carving machine. According to the control instructions sent by the control computer, the wood carving machine is directly driven to produce mechanical motion, and various states of the CNC wood carving machine are detected, and fed back to the control computer and control software for identification and processing.

Factors Affecting of CNC Wood Carving Machine Price

The price of woodworking CNC machine tools varies greatly, ranging from US$2,000 to US$20,000. Different specifications and configurations will result in different prices for CNC woodworking engraving machines. But in general, the larger the size of the CNC milling machine, the higher the price of woodworking CNC machine tools. The higher the configuration, the more functions and the more expensive the price.

1. The work table size: The larger the size of the machine, the more expensive the corresponding price. There are many types of the work table size, which are larger than 600x900mm, 1300x2500mm, and 3000x1500mm.This working size is a very important factor affecting the price of the machine.

2. The spindle power: The spindle power will affect the CNC wood carving machine price. The low-power spindle is mainly used for processing small products, making advertising signs, carving handicrafts, etc. The price of this low-power spindle is relatively cheap. The high-power spindle is mainly used to process large wood, cabinet doors, stone, metal and other materials or to process high-precision products. This kind of high-power spindle is more expensive.

3. In addition to the size of the engraving machine table and the power of the spindle, there are many factors that affect the price of the wood carving machine, such as the motor, body, guide rail and other CNC engraving machine parts. The price of wood CNC milling machine with large size CNC milling machine is higher than that with small size table.