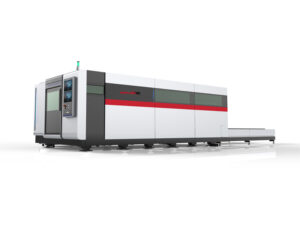

CNC Laser Cutting Machine For Sale

1.What is CNC laser cutting machine?

The CNC laser cutting machine also called the CNC laser cutter, laser cutter CNC, is a laser machine with CNC (Computer Numerical Control) system that uses a laser beam to cut material. The laser cutting machine focuses the laser light emitted by the laser into a high-power density laser beam through the optical path system. The laser beam irradiates the surface of the workpiece to make the workpiece reach the melting point or boiling point, and the high-pressure gas coaxial with the beam blows away the molten or vaporized material. As the relative position of the beam and the workpiece moves, the material will eventually form a slit, so as to achieve the purpose of cutting.

2. What are the main classifications of laser cutting machines?

Laser cutting machines are mainly divided into CO2 laser cutting machines and fiber laser cutting machines. Generally speaking, the fiber laser cutting machine is mainly used for cutting metal materials, such as steel, stainless steel, iron, copper, brass, aluminum, gold, silver, alloy, iron, etc. And the fiber laser cutting machine is also called: metal cutting laser machine, metal laser cutting machine, laser metal cutting machine, laser cutting machine metal, laser cutting machine for metal, CNC fiber laser cutting machine.

And the CO2 laser cutting machine is used for cutting or engraving non-metal material. Such as acrylic, wood, MDF, plastic, leather, paper, polyoxymethylene, glass, rubber, fabric, stone, textile. The CO2 laser cutting machine also is called wood laser cutting machine, laser wood cutting machine, laser cutting machine for wood, acrylic laser cutting machine, laser cutting and engraving machine, laser engraving cutting machine, co2 laser cutting machine, wooden laser cutting machine, wood cutting laser machine, co2 laser engraving cutting machine, co2 laser cutting engraving machine, fabric laser cutting machine, laser cutting wood machine, laser cutting machine for acrylic, laser wood cutter, best laser cutter for small business, co2 laser cutter, laser cutter for wood, laser foam cutter, acrylic laser cutter, paper laser cutter, fabric laser cutter, laser paper cutter, laser cutter acrylic, laser fabric cutter.

3. What are the advantages of the CNC laser cutter machine?

Laser cutting processing is to replace the traditional mechanical cutter with an invisible beam. It has the characteristics of high precision, fast cutting, not limited to the cutting pattern, automatic typesetting, saving material, smooth cutting, and low processing cost. It will gradually improve or replace it. Traditional cutting process equipment. The mechanical part of the laser cutter head has no contact with the workpiece, and will not scratch the surface of the workpiece during work; the laser cutting speed is fast, the incision is smooth and flat, and generally does not need subsequent processing; the cutting heat affected zone is small, the plate deformation is small, and the slit is narrow ( 0.1mm~0.3mm); the incision has no mechanical stress, no shearing burr; high processing accuracy, good repeatability, and no damage to the surface of the material; CNC programming, can process any plan view, can cut the entire board with a large format, without Opening the mold saves time and economy.

4. What are the main parts of CNC Laser cutter?

The laser cutting machine system generally consists of a laser generator, an (external) beam transmission component, a workbench (machine tool), a microcomputer numerical control cabinet, a cooler, and a computer (hardware and software).

1) . The main machine part of the machine tool: the machine part of the laser cutting machine, the mechanical part that realizes the movement of the X, Y, and Z axes, including the cutting work platform. It is used to place the workpiece to be cut and can move it correctly and accurately according to the control program, usually driven by a servo motor.

2) . Laser generator: a device that generates a laser light source. For the purpose of laser cutting, except for a few occasions where YAG solid-state lasers are used, most of them use CO2 gas lasers with higher electrical-optical conversion efficiency and higher output power. Because laser cutting requires high beam quality, not all lasers can be used for cutting. The Gaussian model is suitable for less than 1500W, low-order mode carbon dioxide lasers 100W-3000W, and multimode above 3000W.

3) . Outer optical path: Refractive mirror, used to guide the laser in the required direction. In order to prevent the beam path from malfunctioning, all mirrors must be protected by a protective cover, and a clean positive pressure protective gas should be introduced to protect the lens from contamination. A set of lenses with good performance will focus a beam with no divergence angle into an infinitely small spot. Generally, a lens with a focal length of 5.0 inches is used. The 7.5-inch lens is only used for thick materials >12mm.

4) . Numerical control system: control the machine tool to realize the movement of the X, Y, Z axis, and also control the output power of the laser.

5) . Regulated power supply: connected between the laser, CNC machine tool, and the power supply system. Mainly play a role in preventing interference from external power grids.

6) . Cutting head: It mainly includes parts such as a cavity, focusing lens holder, focusing lens, capacitive sensor, and auxiliary gas nozzle. The cutting head driving device is used to drive the cutting head to move along the Z-axis according to the program and is composed of a servo motor and a screw or gear and other transmission parts.

7) . Operating table: used to control the working process of the entire cutting device.

8) . Water chiller: used to cool the laser generator. A laser is a device that converts electrical energy into light energy. For example, the conversion rate of a CO2 gas laser is generally 20%, and the remaining energy is converted into heat. The cooling water takes away the excess heat to keep the laser generator working normally. The chiller also cools the external light path reflector and focusing mirror of the machine tool to ensure stable beam transmission quality and effectively prevent the lens from being deformed or broken due to excessive temperature.

9) . Gas cylinders: Including laser cutting machine working medium gas cylinders and auxiliary gas cylinders, used to supplement the industrial gas for laser oscillation and supply auxiliary gas for the cutting head.

10). Air compressor, air storage tank: provide and store compressed air.

11) . Air cooling dryer, filter: used to supply clean and dry air to the laser generator and beam path to keep the path and reflector working normally.

12) . Ventilation dust collector: extract the smoke and dust generated during processing, and carry out filtering treatment, so that the exhaust gas discharge meets the environmental protection standards.

13) . Slag discharge machine: remove the leftovers and scraps generated during processing.

5. What are the application field of The CNC laser cutting machines?

1). For the CO2 laser cutting machine, the main application field is as follows:

a)Advertising industry: production of acrylic signs, wooden signs, two-color board signs, advertising characters production, advertising decorations, etc

b)Cloths industry: cutting textiles, cloths…

c)Leather goods industry: Shoes, bags, belts…

d)Wedding industry: customized invitations, souvenirs, customized card

e)Woodworking industry: wood engraving, lettering, carving relief, etc

f)Art industry: architectural model processing, artwork processing, laser engraving, etc.

g)Funeral industry: head shadow engraving, monument engraving, etc.

2). The application of metal laser cutting machines is very extensive, covering many industries, and it is one of the necessary equipment for many companies, including advertising sign production (these are mainly stainless steel LOGO and logo cutting), sheet metal processing (sheet metal cutting) Metal processing basically includes all metal materials. These are generally bending, polishing, etc., and cutting is the most important process among them), chassis and cabinet production (in this regard, carbon steel or stainless steel is generally useful, but also mainly for folding. Bending and cutting 2 cutting processes), springs (belonging to the finishing process), subway parts, as well as the production of elevator casings, mechanical equipment casings, and kitchen utensils (mostly stainless steel), which surpass lasers The laser cutting machine setting of the company is also involved in the production of the seven-seven-shen-eight spacecraft, which actually involves various aspects. Widely used in sheet metal processing, advertising sign production, high and low voltage electrical cabinet production, mechanical parts, kitchenware, automobiles, machinery, metal crafts, saw blades, electrical parts, glasses industry, springs, circuit boards, electric kettles, medical micro Electronics, hardware, knife measuring tools and other industries.

6. The advantages of fiber laser cutting machine

After so many years of development, the laser cutting machine has been applied to many fields by more and more people, and it has been loved by more and more people through its powerful working ability. It is more powerful than CNC engraving machines. Stronger, almost all materials can be processed, and the processing speed is faster, and the processing quality is higher. Then I will introduce you to the advantages of laser metal cutting machines.

1). High cutting accuracy: the laser cutting machine has a high cutting accuracy. The cutting gap produced is parallel to both sides and perpendicular to the surface. The dimensional accuracy of the cut parts can reach up to ±0.05mm, so the metal laser cutting machine can be used for processing Precision machinery and equipment, and it is controlled by a computer, capable of engraving or cutting different materials.

2). Fast cutting speed: The cutting speed of the laser cutting machine for metal is extremely fast. If the 1000w laser cutting machine is used to process 2mm thick steel plates, it only takes a few seconds to successfully process the steel plates. The maximum cutting speed can reach 1500mm/min, we can use a laser cutting machine to produce more products.

3). High cutting quality: The CNC laser cutting machine cuts the products with extremely high quality, almost no light spots and cutting marks, less debris generated by cutting smooth surface of the product, and higher aesthetics of the product.

4). It can effectively avoid tool wear: Because the CNC laser cutting machine is in the studio, it will not contact the workpiece, and the workpiece is processed by the laser beam. No matter what product is processed, there is no need to change the processing tool. The output power of the laser needs to be modified, so this can effectively avoid the loss of processing tools due to friction with the workpiece.

5). The processing process is environmentally friendly and sanitary: another advantage of using a laser cutting machine for processing is that it produces less pollution and is very safe, because the entire processing process is realized by a computer, and workers do not need to process manually, and laser cutting produces There is also very little waste material, which basically does not cause pollution.

Here is the comparison of the fiber laser cutting process and other cutting processes for metal cutting:

Process name | Cutting seam (mm) | Deformed | Precision | Graphical changes | Speed | Machine Cost |

Laser cutting | Very small 0.1-0.3 | Very small | Very high 0.2mm | Very Easy | High | High |

Plasma cutting | Small | Big | High 1mm | Very Easy | High | Low |

Waterjet cutting | Big | Small | High | Easy | High | High |

Die cutting | Small | Big | Low | Hard | High | Low |

Saw cutting | Big | Small | Low | Hard | Slow | Low |

Wire cutting | Small | Small | High | Easy | Slow | High |

Gas combustion cutting | Big | Very big | Low | Easy | Slow | Low |

6. The components of the metal laser cutting machine

The CNC laser cutting machine system generally consists of laser generators, (outside) beam transmission components, worktables (machine tools), microcomputer numerical control cabinets, coolers, and computers (hardware and software).

1). The main machine part of the machine tool: the wood laser cutting machine tool part, the mechanical part that realizes the movement of the X, Y, Z axis, including the cutting work platform. It is used to place the workpiece to be cut and can move correctly according to the control program, usually driven by a servo motor.

2). Laser generator: a device that generates a laser light source. For the purpose of laser cutting, except for a few occasions where YAG solid-state lasers are used, most of them use CO2 gas lasers with higher electrical-optical conversion efficiency and higher output power. Because laser cutting requires high beam quality, not all lasers can be used for cutting. The Gaussian model is suitable for less than 1500W, low-order mode carbon dioxide lasers 100W-3000W, and multimode above 3000W.

3). Outer optical path: Refractive mirror, used to guide the laser in the required direction. In order to prevent the beam path from malfunctioning, all mirrors must be protected by a protective cover, and a clean positive pressure protective gas should be introduced to protect the lens from contamination. A set of lenses with good performance will focus a beam with no divergence angle into an infinitely small spot. Generally, a lens with a focal length of 5.0 inches is used. The 7.5-inch lens is only used for thick materials> 12mm.

4). Numerical control system: control the machine tool to realize the movement of the X, Y, Z axis, and also control the output power of the laser.

5). Regulated power supply: connected between the laser, CNC machine tool, and the power supply system. Mainly play a role in preventing interference from external power grids.

6). Cutting head: mainly includes a cavity, focusing lens holder, focusing lens, capacitive sensor, gas nozzle, and other parts. The cutting head driving device is used to drive the cutting head to move along the Z-axis according to the program and is composed of a servo motor and a screw or gear and other transmission parts.

7). Console: used to control the entire working process of the fiber laser cutting machine.

8). Chiller: used to cool the laser generator. A laser is a device that converts electrical energy into light energy. For example, the conversion rate of a CO2 gas laser is generally 20%, and the remaining energy is converted into heat. The cooling water takes away the excess heat to keep the laser generator working normally. The chiller also cools the external light path reflector and focusing mirror of the machine tool to ensure stable beam transmission quality and effectively prevent the lens from being deformed or broken due to excessive temperature.

9). Gas cylinder: Including the working medium gas cylinder and gas cylinder of the laser cutting machine, which are used to supplement the industrial gas for laser oscillation and supply the gas for the cutting head.

10). Air compressor, air storage tank: provide and store compressed air.

11). Air cooling dryer, filter: used to supply clean and dry air to the laser generator and beam path to keep the path and reflector working normally.

12). Ventilation dust collector: extract the smoke and dust generated during processing, and filter it, so that the exhaust gas discharge meets environmental protection standards.

13). Slag discharge machine: remove the leftovers and scraps generated during processing.

CNC Fiber Laser Cutting Machine For Sale

Related Article about Fiber Laser Cutting Machine for metal

Fiber Pipe Laser Cutter Is Popular In Door And Window Industry

Table

Customer reviews and testimonials of CNC Laser Cutting Machine

1. Macker Chandler

From the USA

10. Oct 2021

I bought a small metal cutting laser machine from BuyCNC. It has brought me a lot of profits and I am very satisfied.

2. Ronaldo Sanchez

From France

9. Oct 2021

I bought a very beautiful metal cutting laser machine for my new factory. This machine is very beautiful and has strong processing capabilities.

3. Jason Wilson

From the United States

5. Oct 2021

My friend recommended BuyCNC to me. I bought a laser welding machine from it. The price of this machine is very cheap, so I paid for it.

4. Jacob Muller

From Germany

3. Oct 2021

The laser engraving cutting machine that I am most satisfied with, my workers can use it proficiently.

5. Noval Lisbon

From Spanish

23. Sep 2021

I have a small metal processing factory, and I searched a lot of metal laser cutting machines on Google. Finally, I chose to buy a metal cutting laser machine from BuyCNC.

6. Betis Noel

From Finland

20. Sep 2021

I did not expect that the processing capacity of this laser wood cutting machine is so strong, it is even faster than the processing speed of two CNC wood routers.

7. Chris Johnson

From the UK

15. Sep 2021

This supplier has various laser engraving cutting machines, such as the acrylic laser cutting machine, laser key cutting machine, and fabric laser cutting machine.

8. Jefferson Williams

From the USA

12. Sep 2021

I am very satisfied with this purchase experience. I bought two laser wood cutting machines at BuyCNC and they gave me a big discount. Thank you.

9. Daniel Smith

From Canada

10. Sep 2021

I sold my old laser wood cutting machine and bought the newest model of laser wood cutting machine here. I am very satisfied with the performance of this machine.

10. Mendy Cole Chrislovsky

From Russian

4. Sep 2021

I selected many fiber laser cutting machine vendors on Google, and finally, I chose them.