Table of Contents

What is The Metal Cutting CNC Router

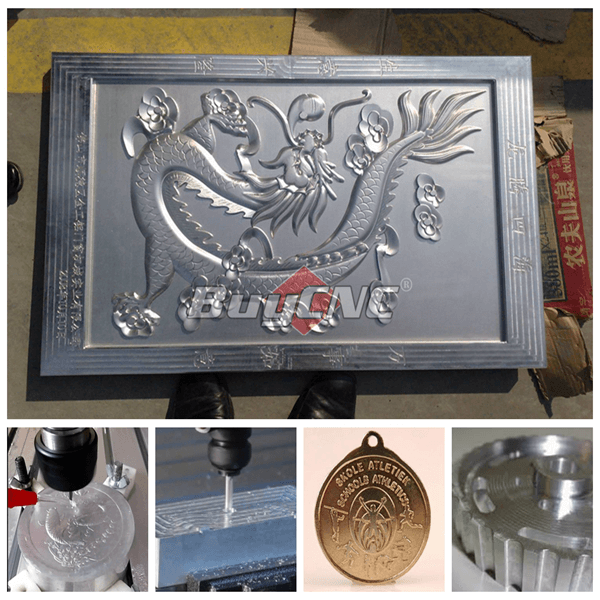

The metal cutting router is a CNC router machine specially used for processing metal, this CNC routet metal cutting machine can be used in processing almost any metals, such as the aluminum, iron,, steel, copper, stainless steel and other metals. This machine is a computer numerical controlled machine for carving, cutting, molding or milling metal materials. A metal CNC machine is also known as CNC metal machine, CNC metal router, metal CNC router, metal carving machine, metal engraving machine. Because of this metal cutting CNC router Hard metal needs to be processed, so the quality of the machine is very strong, most of which are welded from cast iron frames. The machining accuracy of this machine is very high and can complete high-quality cutting. Now with the development of the CNC engraving machine for metal, it has been widely used in many industries.

Nowadays, most of the metal cutting cnc router on the market have the function of one machine and dual purpose, that is, it can engrave and cut products such aluminum plate, iron and other metals.The effect is very real. Due to the use of vacuum adsorption tabletop technology, materials of different areas can be adsorbed efficiently, and with the help of high-power imported electromechanical devices, it can work continuously for 12 hours a day, and the work efficiency is extremely high.CNC metal cut machining is a manufacturing process that involves using high speed, computer-controlled, precision machines to remove plastic or metal from a blank, a block of metal or plastic, to create a part. The process is subtractive, meaning the machine removes material from the blank to reveal the final part.

Advantages of Metal Cutting CNC Router

Metal cutting CNC router has gradually developed into an independent processing center, which is widely used in building doors and windows, curtain walls, architectural decoration, and vehicle and ship decoration industries.

In view of the characteristics of metal materials and processing technology, CNC router metal cutting machines generally have the capabilities of milling, drilling, and tapping; while functions such as milling planes/curved surfaces, countersinking, and boring are seldom used in aluminum profile processing. Due to the uniqueness of the processing objects, the big metal cutting cnc router is very different from the general machining center in terms of structural layout, technical parameters and CNC system design.

1. Large processing area

In order to adapt to the characteristics of metal parts, the CNC router metal engraving machine work surface is mostly narrow and long. The work surface is standard equipped with pneumatic fixtures and positioning backing plates, which is convenient for workpiece positioning and clamping. Aluminum engraving machine has three layouts: gantry type, moving column type, and moving beam type. The three layouts have their own advantages and disadvantages in terms of machine rigidity, stable operation, and convenient operation.

2. High spindle speed

The spindle speed of an ordinary CNC router machine is generally below 8000rpm; while the spindle speed of a metal cutting CNC router machine can reach or exceed 18000rpm. Due to the high speed, a high-power integrated spindle is generally used to clamp the tool, blow air to clean, and circulate water to cool And other functions are integrated in one. The cooling liquid system is divided into two forms: pouring cooling and spray cooling. The latter belongs to the more advanced concept of quasi-dry cutting and micro-lubrication system, which has high cooling and lubrication efficiency and low coolant consumption, and is especially suitable for metal processing.

3. High precision and moderate rigidity

The processing accuracy of frame, stile, truss and other profiles involved in doors, windows and curtain walls is generally between IT10 and IT12; plus the processing objects are mostly metal, metal cutting CNC router does not need to pursue excessive positioning accuracy and rigidity. The bed and other structural parts of the aluminum engraving machine are mostly welded by steel plates, so the quality of the machine is high and the service life is longer.

4. High processing efficiency

Improving processing efficiency is the main goal pursued by metal cutting CNC router. By increasing the rapid feed rate, shortening the tool change time, tool-free setting and fast loading, the auxiliary time and idle travel time are shortened. Engraving machine manufacturers strive to improve the automation of workpiece positioning and card assembly by summarizing the problems encountered by customers in various regions.

CNC router metal engraving machines are generally equipped with pneumatic fixtures and positioning backing plates. The positioning backing plate is a positioning device driven by an air cylinder, which extends when loading and unloading the workpiece; retracts at the beginning of processing to avoid interference. During use,the profile can be positioned against the board to obtain precise positioning.

Before the machine leaves the factory, the relative position of the positioning backing plate and the machine origin is accurately adjusted, and the data is stored in the CNC system, so the tool setting process can be omitted. Pneumatic fixtures are operated by buttons or foot switches. The clamping position can be adjusted longitudinally in the machine tool to avoid interference, and at the same time ensure reliable and effective clamping.

Applications of Metal Cutting CNC Router

This metal cutting CNC router has powerful processing capabilities,Therefore, the CNC router metal cutting machine has been welcomed by more and more people. And this machine has been widely used in many processing fields. Next, we will introduce you to several major application industries of metal cutting CNC router.

1. Advertising and gift manufacturing industry: The metal cutting CNC router can be used to carve all kinds of two-color plate signs, plexiglass, Vatican stone doorplates, three-dimensional billboards, decorative gifts, light box tablets, two-color human statues, embossed medals, and wall-mounted lamps Products such as housing, light guide plate carved lamp house, organic plate embossed three-dimensional door head and other products.

2. Mold manufacturing industry: This metal cutting CNC router can realize engraving and engraving button relief molds, printing and hot stamping molds, injection molds, blow molds, stamping molds, eye molds, etc.

3. Automobile manufacturing industry: This machine can produce a variety of metal products such as automobile parts and automobile models.

4. Other industries: The metal cutting cnc router can be used in model manufacturing, mechanical processing industry, decoration industry and other industries.

How to Choose The CNC router sheet metal

How to choose the right CNC router metal cutting machine

With the further development of the engraving machine industry, more and more metal engraving machines have appeared on the market, and these engraving machines have powerful processing capabilities. So do you know how to choose the right CNC router metal engraving machine?

1. Processing materials: First of all, it is necessary to clarify what kind of materials need to be machined. If you want to process large or thick materials, then please choose a large CNC router metal cutting machine. If it is used for thin plate processing, and the budget is not very large If it is high, please choose a small metal engraving machine.

2.Metal Engraving machine function : the metal engraving machine has a variety of power engraving machines. The low-power engraving machine is only suitable for cutting thin plates, making signs, engraving handicrafts and other industries. The other is a high-power engraving machine, this CNC The router metal cutting machine has a large processing table, which can process large workpieces, and can be equipped with high-precision cutting heads to achieve fine processing functions.

3. Cutting speed: The cutting speed of the engraving machine has an adjustable range. Generally, the adjustable range of speed is from a few thousand to 18000 revolutions. If the speed range cannot meet your cutting needs, then you need to choose a suitable machine, because The cutting speed of engraving different metal materials is also different.

4. Engraving machine accessories: Engraving machine accessories are also an important factor affecting the choice of engraving machine, such as servo motor and stepper motor, rack and pinion and other accessories. It is also very important to choose a CNC router metal cutting machine with high-quality accessories.

How to use metal engraving machine

1. Open the CNC router sheet metal machine engraving programming software and program the engraving path: Let’s take an example, engraving text, first use the software to layout, and then use 2D, 3D, cut, and enter the depth, Parameters such as overlap rate and line spacing are calculated on the computer. When processing the relief, first use ARTCAM or fine engraving to generate the relief from the file or model image, determine the size, input the processing parameters, and the computer starts the calculation. When generating paths, colored lines will be generated for words or models.

2. Output engraving path and input engraving machine control system software: In the output files of software such as Wentai, Jingdiao, ARTCAM, etc., if the engraving machine control system cannot support the format, it needs to be converted. Common program formats are nc, mmg, etc.

3. Check the machine and fix the workpiece correctly: Check whether there are debris on the machine tool, especially stone, large-area stone powder, sand, etc., pay attention to cleaning, otherwise it will easily affect the flatness of the material. Place the workpiece according to the placement direction in the typesetting programming software, depending on whether the material is placed horizontally or vertically. Note that the material and the machine are parallel to the direction of the axis, and do not put it off. Use the pressure plate to fix the material, the general fixing methods are pressure and upper two. When pressing with a pressure plate, please be careful not to press the processed part of the material to prevent mechanical collision or tool collision.

4. Determine the origin of the workpiece coordinate system, which is what we often call tool setting. Align the origin of each axis of the machine with the original point, and then return the data to zero or enter the coordinates of the corresponding coordinates.

5. Detect water spray and water circulation, adjust the mechanical speed and feed speed, and simulate in the aluminum plate engraving machine control system.

6. Start the engraving machine.

7. Processing is completed. Confirm whether the engraving effect is satisfactory and whether it needs to make up

Precautions for Metal Engraving Machine:

1. The continuous operation time per day should not exceed 10 hours. It is necessary to ensure the cleanness of the cooling water and the normal operation of the pump, and to replace the cooling water regularly to avoid water shortage in the water spindle motor. If the ambient temperature is too low in winter, the water in the water tank can be replaced with antifreeze.

2. Every time the machine is used, the dust on the platform and transmission system must be removed.

3. The X, Y, and Z three-axis polished rods are maintained with oil; the screw part is added with high-speed butter; if the working environment of the automatic computer engraving machine is too low in winter, the screw and polished rod (square rail or round rail) part should be used first Gasoline is flushed and cleaned, and then the engine oil is added, otherwise it will cause excessive resistance in the transmission part of the machine and cause the machine to displace.

The use of metal engraving machine is required, otherwise it will affect the accuracy of the engraving machine. It is recommended that you can refer to the above-mentioned engraving work to improve the utilization rate, so that the equipment can meet the basic requirements of users, and produce products that meet the standards for use .

Summary

BuyCNC has a variety of CNC router machine for metal for customers to choose from. If you do not know how to buy the most suitable CNC router metal engraving machine after reading the above, please leave your contact information and we will contact you immediately , And provide you with the most professional services.

Related Blogs About CNC Router

The Complete Guide to CNC Woodworking Machines: Revolutionizing the Woodworking Industry

Table

The Ultimate Guide to CNC Wood Routers: Everything You Need to Know

Table