Table of Contents

Why CNC Metal Routers Are Popular

BuyCNC as a supplier engaged in the CNC router machine industry for many years, found that the sales of CNC metal routers are gradually increasing recently. Do you know why the metal CNC router is popular with buyers? Then follow BuyCNC to learn more about CNC metal router machine.

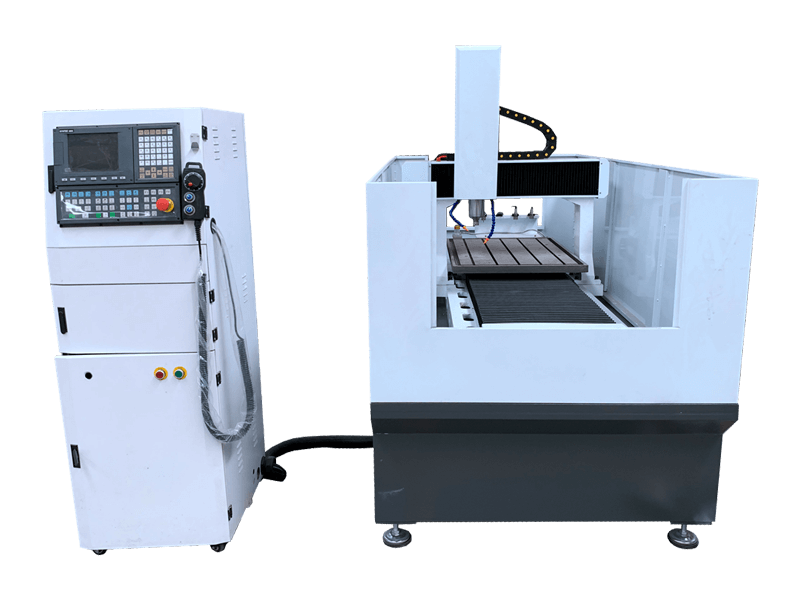

BuyCNC’s metal engraving machines are made of high-quality accessories from well-known brands, which makes the machine have extremely high precision, stable operation, low failure rate, stable body and long service life. The Z-axis is matched with an industrial-grade ball screw to enable accurate positioning of the machine and improve processing quality. This CNC machine also supports functions such as breakpoint continuous engraving, breakpoint recovery, and automatic tool setting. The machine also has an oil mist cooling system, which can clean up the dust in time and improve the processing quality. You can also choose a dust absorber to make your processing workshop very clean. As an industrially produced model, the body of the machine is welded by a heavy-duty all-steel structure, and the thickened table top and gantry beam structure enable the machine to process heavy metals. The screw connection of all parts of the machine can be loosened 100 times without breaking the wire, which is good for replacing parts and will not affect the rigidity and durability of the machine.

Our metal CNC cutting router supports a variety of application software and control systems, and is compatible with Vectric Aspire, Type3, Ucancam, Artcam, AlphaCam, Powermill, Solidworks, and other CAD/CAM planning and production software. At the same time, you can also choose a variety of control systems, such as Mach 3 Controller, DSP handheld controller, NC-studio controller and Syntec controller. So you can choose the metal CNC router machine that best meets your requirements.

Have you heard of such a cheap Metal CNC router machine? Come and take a look at this machine. Its price is only US$2,600. This machine is a desktop CNC machine, it has a small footprint, is easy to move and is cheap. This machine can be used to process soft metals such as aluminum and brass, as well as wood, plastic, foam and other materials. This metal CNC cutting machine is a cast iron frame with a very stable structure and a long service life. If you want to know more, please contact BuyCNC.

How To Choose Suitable CNC Metal Machine

With the rapid development of CNC metal cutting machine, it has been widely used in many industries, such as sheet metal processing industry, cutting and engraving various metal plates. There is also the advertising industry, which uses metal CNC router to produce billboards, as well as the mold manufacturing industry, metal cabinet door industry, etc. So do you know how to choose the most suitable CNC metal cutting router.

1. Pay attention to the power of the CNC metal cutting machine, which has high power and low power. Some low-power metal CNC machines are only suitable for processing two-color plates, small models, small signs, three-dimensional crafts and other products. This technology has been popular for a while, but the scale of its use is greatly affected by the small carving power. The other is a high-power CNC machine for metal. This CNC metal engraving machine is divided into two categories. One is a large table cutting machine: the size of the table is generally more than one meter, but this kind of metal engraving machine The accuracy is generally poor, mainly used for sheet metal processing; the other is high-precision metal engraving machine: this kind of metal engraving machine is generally used for precision processing.

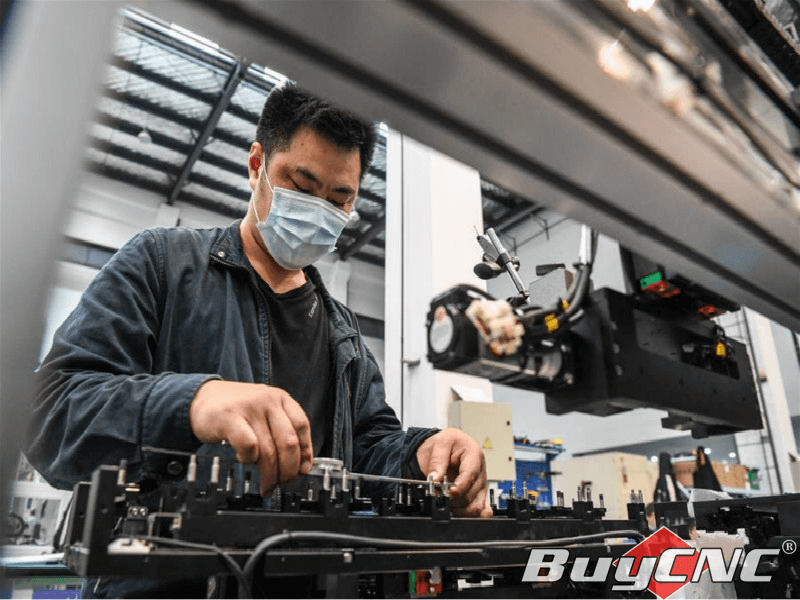

2. To understand the accessories and machine structure of the metal engraving machine, the accessories of the metal engraving machine are very important, because as a large-scale mechanical equipment, no matter which accessory is very important. Metal itself is a heavier material. When choosing a metal CNC cutting machine, the quality of the machine is also very important, because the machine must be precise and stable when it works. Therefore, a high-quality metal CNC router machine should use solid materials to produce the machine. Only in this way can it prove its machining accuracy and stability.BuyCNC’s metal engraving machines are made of cast iron. This kind of machine has a stable structure and a long service life.

3. There is also the adjustable speed range of the CNC metal milling machine. The general speed adjustable range is several thousand to 30,000 revolutions per minute. If the speed is not adjustable or the speed adjustable range is small, then when you are using this machine CNC metal milling machine will be subject to certain restrictions, because processing different materials requires different cutter heads and speeds.

4. Controllers are generally divided into two types: the first type of controller is only used for driving, and all its calculation tasks are completed by the computer. When the metal engraving machine is working, the computer is in a waiting state and cannot perform typesetting tasks. Another type of controller is controlled by a single-board computer or a single-chip computer. This controller is actually a computer, so as soon as the metal engraving machine starts to work, the computer can immediately perform other typesetting tasks, especially when carving for a long time. , This advantage is particularly significant.

5. The screw rod and guide rail are also an important part of the metal engraving machine. Because the CNC metal cutting machine needs a transmission system to integrate the machine, a good screw rod and guide rail are the precision and accuracy of the metal engraving machine when it is used for a long time. Performance guarantee. BuyCNC uses high-quality screw rods and guide rails.

This is a large CNC metal cutting machine for sale. It is now generally used in the mold manufacturing industry. It can quickly process various metals, and the walls on both sides of the workbench can prevent dust from flying out. And this metal CNC milling machine is equipped with a 4 Position auto-Tool Magzine, so we can choose different cutting tool to process different materials. Moreover, the work table of this machine is movable, so the accuracy of the machine will be higher.

11 Notes About Metal CNC Router

1. First determine whether the voltage of the CNC metal router machine is 220 volts or 380 volts. Do not use it blindly, otherwise the machine will be damaged.

2. Determine whether the voltage in the workshop meets the requirements. The normal voltage should be between 210V-230V. If it does not meet the requirements, a voltage stabilizer must be used. When choosing a voltage stabilizer, you must choose a high-quality one (the power is above 2000W, and the general weight should be above 15 kg).

3. The metal CNC cutting machine must be grounded. One is to ensure the safety of the machine, and the other is to avoid electrostatic interference.

4. Because the CNC metal cutting machine belongs to precision numerical control equipment, if there is no professional guidance, please do not disassemble the parts and adjust the electrical accessories, especially the inverter, otherwise it will cause the machine failure rate to increase.

5. This CNC metal machine needs long-term maintenance to ensure the lubrication of the machine and frequent dust removal, etc.; keep the guide rails and lead screws clean and lubricated.

6. The cooling system must be carefully checked every day, and the circulating cooling system must be ensured to operate normally, and the cooling function of the spindle must be ensured, otherwise the spindle will be burnt out.

7. Spindle motor protection: If the engraving motor stops rotating or the motor speed is uneven, please cut off the power immediately and contact the buyer. If the motor cannot be energized when the motor is stopped, otherwise the motor will burn out immediately, please pay attention to the buyer when using it! ! ! !.

8. The protection of the chuck: The motor chuck and the tool are fixed by metal friction, so it should be lubricated regularly to prevent disassembly difficult due to long-term non-disassembly or coolant corrosion.

9. Clean the heat dissipation and ventilation system of the circuit box regularly. Please regularly check whether the fans on the electric control box are working properly. Use a vacuum cleaner to clean the dust in the electric control box regularly. Check whether the terminal screws are loose to ensure the safety and reliability of the circuit. use.

10. The door of the electric control box should be opened as little as possible, and it is forbidden to open the door. There will be dust, wood chips or metal powder in the air during engraving. Once they fall on the circuit board or electronic device in the electric control box, it is easy to cause components The insulation resistance between the devices decreases, even causing damage to the components and circuit boards.

11. Regularly check whether the screws of each part of the machine are loose.

This machine can carry out 2D and 3D engraving and cutting of metal or non-metal. Its worktable size is 600x900mm, which can meet the requirements of processing small workpieces. And the price of this machine is very cheap. If you want to have a machine capable of 3D processing, this machine is a good choice.

Summary

Through the above article, do you have a deeper understanding of CNC metal router machine. BuyCNC has multiple types of CNC metal cutting and engraving machines. If you want to have your own metal CNC router machine, please contact BuyCNC. This machine is not as expensive as you think, on the contrary, they are very cheap. If you have any ideas, please contact us as soon as possible.