Table of Contents

Nowadays, metal products have been widely used in people’s lives, and the application of sheet metal and pipe fittings is very extensive. With the continuous increase in market demand, the processing market of sheet metal fittings is also growing. The traditional processing method can no longer meet the requirements of the rapidly developing market and low-cost production mode, so the integrated plate and tube laser cutting machine with both cutting board and tube cutting has come out.

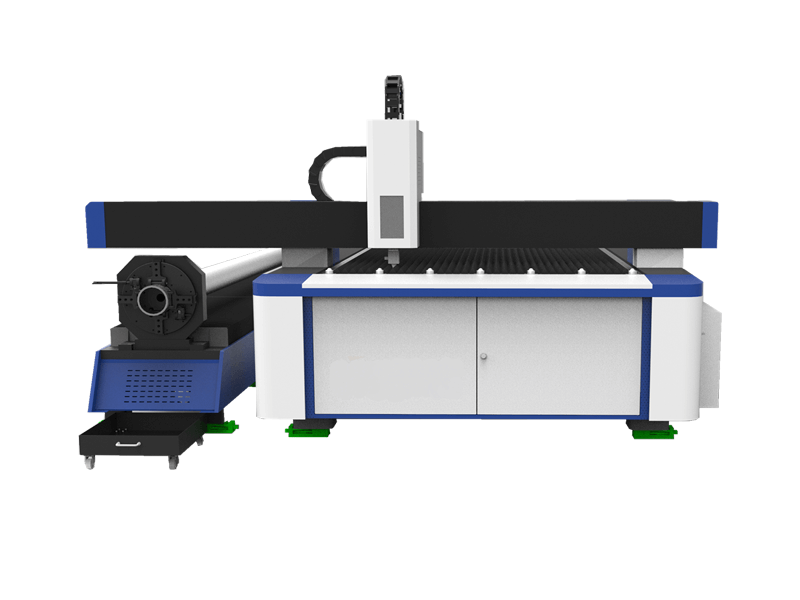

The plate and tube dual-purpose laser cutting machine is a professional equipment mainly for metal sheets and pipes. Because it is a laser cutting process, it has great advantages over other equipment in cutting, and can cut various complex graphics well. Because it can process two types of metal parts at the same time, it quickly occupied the metal processing market once it came out, and has been widely used in sheet metal parts processing and parts processing industries. And now more and more construction industry practitioners choose to use metal sheet and tube fiber laser cutting machine to produce metal stairs.

Why choose plate and tube fiber laser cutter to make metal stairs

Many people have a LOFT dream in their hearts. It is simple and casual, free and comfortable. The open layout with few partitions allows people to boldly break through the tradition and create their own according to their own life needs and aesthetic tastes. ideal life. Stairs are the bridge connecting the upper and lower spaces, and also the soul of a LOFT. Iron staircases are one of the stair designs. Because of the sturdy structure of metal materials, high safety and easy maintenance, many people think about the material of stairs. Preferred.

Compared with conventional metal processing methods, tube sheet metal cnc fiber laser cutting machine has excellent adaptability and flexibility, which can provide more space for the design and production of stairs. Iron staircases generally have hanging and veneer types. Whether it is a staircase composed of simple metal plates or a complex and gorgeous hollow carved staircase, the fiber laser cutting machine can quickly and accurately complete the cutting work, reflecting the beauty of metal lines and showing the beauty of craftsmanship incisively and vividly. , bringing vitality to the whole space.

The metal plate and tube laser cutting machine, which integrates cutting, hollowing and punching, realizes the diversification and multi-functionality of furniture products, promotes the development of the furniture industry, and changes people’s attitudes invisibly. The quality of life also provides strong technical support for the sheet metal processing industry. This fiber 3d laser metal cutting machine can complete the construction of stairs with high quality and improve the processing efficiency, so it has been warmly welcomed in the construction field.

Advantages of Fiber 3d laser metal cutting machine for metal processing

1. Laser processing does not require mold opening, and there is no need to make molds for different designs, saving a lot of production costs;

2. Metal sheet and tube fiber laser cutting machine has high flexibility and unlimited graphics. Whether it is a simple or complex shape, it can be formed by laser cutting at one time, and it can also realize automatic cutting layout and nesting, which improves the utilization of materials. Rate;

3. Metal tube and plate fiber laser cutting machine has fast cutting speed, high precision, smooth cutting edge and no burrs, which reduces the defect rate of products and shortens the production cycle of products;

4. Plate and tube fiber laser cutter will not produce chemical substances that are harmful to human body and the environment, and meet the national environmental protection requirements. It reduces environmental pollution and helps furniture manufacturers to optimize the working environment.

5. The laser cutting machine does not produce chemical substances that are harmful to human body and the environment, and meets the national environmental protection requirements. It reduces environmental pollution and helps furniture manufacturers to optimize the working environment.

Features of Plate and tube fiber laser cutter

◆The metal sheet and tube fiber laser cutting machine is equipped with a special platform for laser cutting machine, the plate and tube can be switched at any time, the front is docked, and the side operation is accessible;

◆The processing point of the cutting mechanism of the Fiber 3d laser metal cutting machine is placed inside the safety shield, and the operator is guaranteed safety protection;

◆The pipe cutting mechanism feeds 1.5 meters at a time. After cutting, it feeds and processes one by one, which can complete the cutting of raw material pipes of more than 6 meters;

◆The tube sheet metal cnc fiber laser cutting machine can be equipped with different types of jaws to realize the cutting of different profiles, such as: angle steel, channel steel, I-beam;

◆Metal plate and tube laser cutting machine adopts gantry structure, high-strength welding frame, overall stress relief treatment, good rigidity and small deformation;

◆This metal tube and plate fiber laser cutting machine is driven by high-precision servo motor, equipped with high-precision transmission mechanism, with high installation accuracy, large transmission torque, small transmission error and good dynamic characteristics;

◆Metal sheet and tube fiber laser cutting machine has built-in process database, simple and intelligent operation, and also has safe and reliable external protection device, adopts safety interlock design, high safety, and can be used with confidence;

◆The fiber 3d laser metal cutting machine is equipped with a special workbench for pipe cutting, which assists the processing and cutting of long pipe workpieces, improves processing efficiency and avoids accidents.

The advantages of plate and tube integrated laser cutting machine compared with tube laser cutting machine

First of all, the laser pipe cutting machine is aimed at cutting all kinds of pipes. It is suitable for all kinds of round pipes, square pipes, rectangular pipes, flat pipes, U-shaped pipes and special-shaped pipes. At the same time, it can be punched and beveled when cutting , micro-connection and other cutting processes. Metal sheet and tube fiber laser cutting machine can cut metal sheets and metal pipes. One machine is multi-purpose. Most of the functions that professional laser pipe cutting machines can achieve can also be achieved by plate and tube integrated laser cutting machines. Therefore, the metal tube and plate fiber laser cutting machine more popular.

Secondly, the functional characteristics of the two are also different

3 advantages of laser pipe cutting machine:

1. Multiple cylindrical intersecting holes of different directions and different diameters can be cut on the main pipe to meet the conditions of eccentric and non-eccentric vertical intersection between the axis of the branch pipe and the axis of the main pipe.

2. The end of the cylinder intersection line can be intercepted at the end of the branch pipe to meet the conditions of eccentric and non-eccentric vertical intersection and oblique intersection of the branch pipe axis and the main pipe axis.

3. It can cut the inclined end face of the end of the round pipe and the square pipe, and can cut various hole types on the round pipe and square pipe to meet various processing needs.

3 advantages of Plate and tube fiber laser cutter:

1. The Metal plate and tube laser cutting machine is equipped with a double platform for cutting plate and tube, which can realize the function of double cutting of plate and tube. One piece of equipment can complete multiple processes, which can not only reduce the floor space of the equipment, but also reduce the cost investment of the equipment.

2. The laser processing adopts a unified fixture and tooling, and the entire processing process is completed by the programming software. Using laser cutting to process products, the cutting section is smooth, the cutting seam is small, and the overall workpiece is not deformed, and the next step can be directly entered.

3. The processing speed of Tube sheet metal CNC fiber laser cutting machine is dozens of times that of traditional processing methods, which can realize batch processing. During the processing, the cutting board and tube cutting can be converted at any time, and the production efficiency is greatly improved.

Combined with the actual situation, although both have their own advantages, there is no absolute advantage, only suitable for their own equipment. For example, for sheet metal processing plants, both plates and pipes are involved. When the processing of pipe fittings is small but necessary, it is very suitable to choose a plate-and-tube integrated machine. Just a small amount. Well, having said that, have you already had a general understanding of the model you are going to choose? If so, you are welcome to visit BuyCNC.