Table of Contents

Stainless steel, with its weldability, corrosion resistance, polishing, heat resistance and corrosion resistance, has always been the darling of the emerging processing industry. The professional 2kw fiber laser cutting machine can provide all metal processing industries. A good competition platform to promote the rapid development of the industry. Due to the high plasticity and toughness of stainless steel plate, the surface is particularly smooth and not easy to rust, so it is very common in the market. Various daily necessities, parts and accessories are all It is made of stainless steel. Therefore, it is very necessary to use a professional 2kw fiber laser cutter. Only with advanced equipment can various stainless steels be made into beautiful products. For example, this stainless steel distribution box is a stainless steel distribution box made by cutting stainless steel by laser fiber machine 2kw.

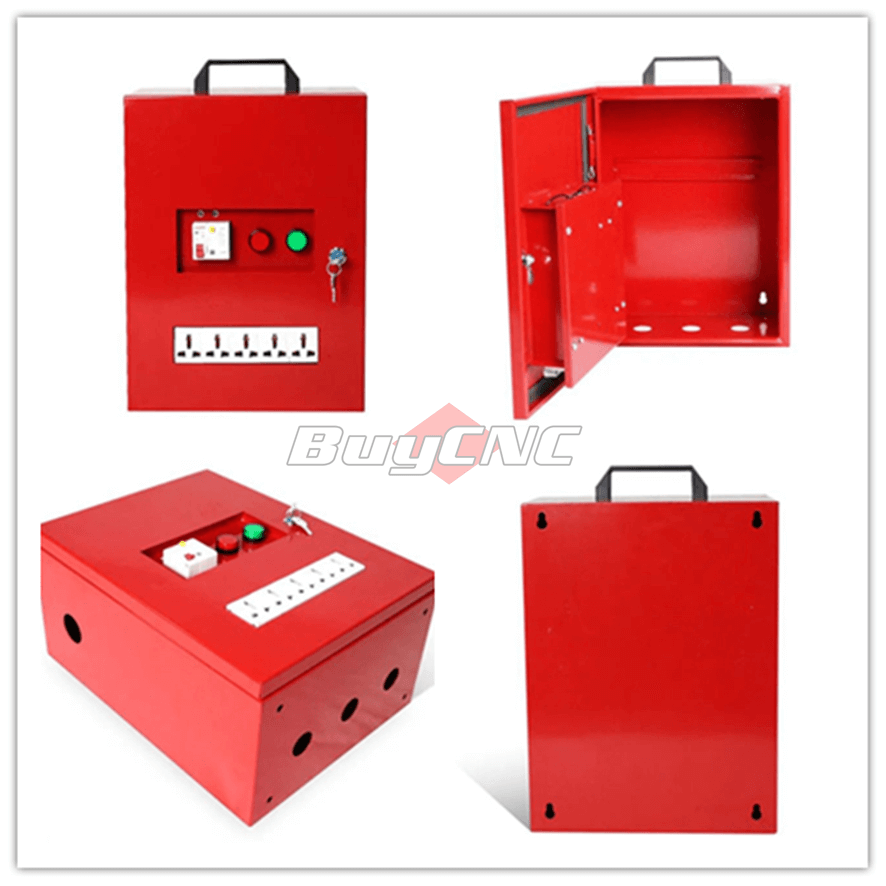

2kw fiber laser cutter to produce stainless steel distribution box

The function of the distribution box is to cut off and connect the power supply, effectively control each power line, and achieve the purpose of safe electricity use. From small to every household, to every building, it needs to be controlled and protected by the distribution box. . Laser-cut stainless steel distribution box, non-standard customization, extremely fast, good-looking, long service life, not easy to damage.

The distribution box is made of stainless steel. Stainless steel has the advantages of anti-corrosion, anti-rust, strong and durable, and is not afraid of environmental differences. It is not easy to be damaged by long-term sun and rain. Cutting, rain shelter cutting, galvanized bottom plate cutting, hollow out the heat dissipation hole, hollow out the wall hole, hollow out the outlet hole.

China 2kw fiber laser cutting machine is especially suitable for cutting and hollowing out sheet metal. It has fast cutting speed, good quality, no cutting force, and no deformation during processing. It can quickly and accurately complete the processing of distribution boxes, and vividly shows the beauty of metal lines. .

Distribution boxes are generally non-standard products and require customized processing. Compared with conventional processing methods, fiber laser cutter 2000 watt has excellent adaptability and flexibility, which can provide more space for the design and production of distribution boxes. , can carry out personalized processing according to specific design drawings, no matter how complex the graphics, can achieve cutting without increasing cost, small batch, multi-variety, low-cost, fast processing, laser cutting “tailored” for users.

Why do stainless steel processing manufacturers use laser cutting machines?

1. fiber laser cutting machine is a kind of metal forming equipment, its main cutting material is not limited to stainless steel, it can be used for cutting stainless steel, carbon steel, alloy steel, silicon steel, spring steel and other metals. The main principle is to use the energy released when the laser beam is irradiated on the surface of the stainless steel plate to melt and evaporate the stainless steel to finally achieve the effect of cutting the plate.

2. With the continuous development and progress of industrial manufacturing, the application of stainless steel has been very extensive. It is used in household products, electronic appliances, vehicles, building materials, industrial machinery and other fields. Stainless steel is composed of steel with a carbon content of less than 1.2% and chromium with a content of more than 10.5%. It is also famous for its low rust resistance and high corrosion resistance.

3. At present, the processing of stainless steel is mainly based on laser cutting. The laser cutting technology uses a fiber laser beam to act on the surface of the material on a small scale. The high-density and high-energy laser beam heats the stainless steel plate locally and evaporates the area, thereby realizing the cutting of stainless steel. .

4. Stainless steel laser processing has a variety of focusing methods. The commonly used two are direct focusing with focusing mirror and galvanometer plus flat field mirror. The combination of galvanometer and flat field mirror is widely used for its advantages of fast processing speed and wide application range. This focusing method has no requirements on the laser light source, and can carry lasers of various wavelengths and pulse widths. The types of processing materials are mainly thin plates, such as stainless steel plates, carbon steel plates, aluminum alloys and composite metal plates, so the laser fiber machine 2kw can process a variety of materials.

5. Stainless steel is used in a wide range of applications, such as kitchen equipment, general tensile materials, gas stoves, refrigerators, electrical appliances, washing machines, dryers, microwave ovens, electronic components, steel pipes, decorative pipes, structural pipes, exhaust pipes, building materials, Regrinding, elevators, building interior and exterior decoration materials, windows, door materials, chemical equipment, heat exchangers, boilers, tanks, etc., it can be seen that stainless steel is widely used.

Principle of 2kw fiber laser cutting machine

China 2kw fiber laser cutting machine occupies a large proportion in industrial production. The main area of stainless steel and low carbon copper is the difference in their composition, and the cutting mechanism is also different. Stainless steel contains 1% to 20% chromium which tends to destroy the oxidation process.

During cutting, the iron in the stainless steel will have an exothermic reaction with oxygen. The oxidation of chromium has the property of preventing oxygen from entering the molten material, and reducing the amount of oxygen entering the molten layer. The oxidation of the molten layer is incomplete, the reaction is reduced, and the cutting speed is reduced. reduce. Compared with low carbon steel, stainless steel cutting requires higher laser power and oxygen pressure. Although stainless steel cutting can achieve satisfactory cutting results, it is difficult to obtain a completely slag-free cutting seam. Using inert gas as auxiliary gas to cut stainless steel can obtain non-oxidative trimming, which is directly used for welding, but its cutting speed is about 10% lower than that of oxygen as auxiliary gas.

Advantages of 2kw fiber laser cutter

1. The 2kw fiber laser cutting machine cutting metal does not need to open molds, and do not need to make molds for different designs, saving a lot of production costs;

2. The 2kw fiber laser cutter has high flexibility and unlimited graphics. Whether it is a simple or complex shape, it can be formed by laser cutting at one time, and it can also realize automatic cutting layout and nesting, which improves the material utilization rate;

3. Fiber laser cutter 2000w has fast cutting speed, high precision, smooth cutting edge and no burrs, which reduces the defect rate of products and shortens the production cycle of products;

4. Fiber laser cutter 2000 watt will not produce chemical substances that are harmful to human body and environment, and meet the national environmental protection requirements. It reduces environmental pollution and helps power distribution box processing manufacturers to optimize the working environment.

5.3015 fiber laser metal cutting machine is higher in cost than wire cutting, and its precision is not as good as wire cutting, but its speed is twice that of wire cutting, which can realize mass production, and can process non-metallic materials after cutting, realizing intelligent One machine replaces multiple stages and becomes the core of the processing equipment. It can be seen that stainless steel laser cutting is a fast and effective processing method.

6. Traditional stainless steel cutting requires die cutting or saw blade cutting. This method has a slow processing speed and low precision, and is only suitable for ordinary or low-demand processes. With the advancement of technology, laser cutting machines, laser engraving machines Such laser equipment has become the first choice for the stainless steel processing industry.