Table of Contents

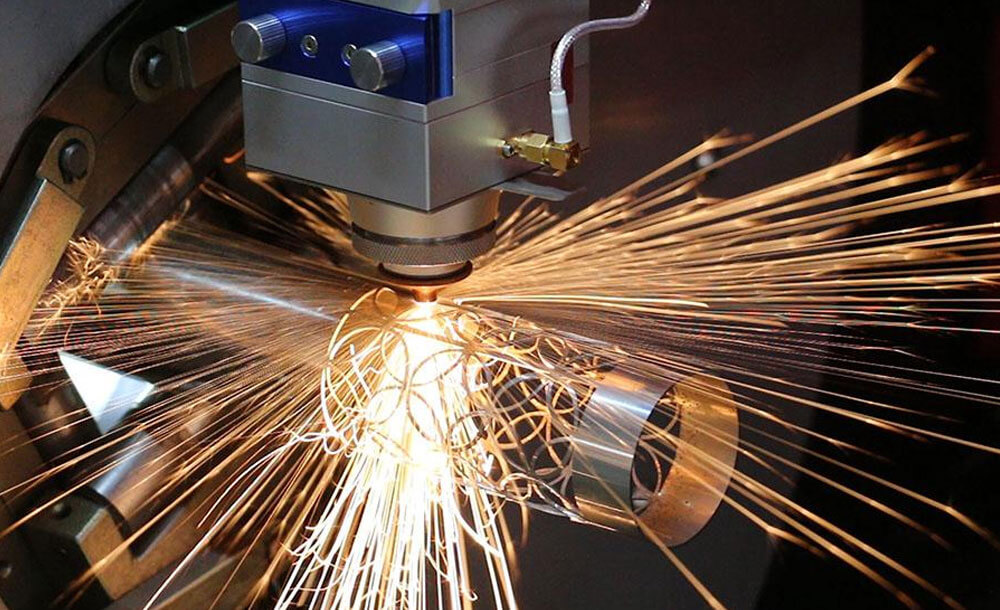

With the improvement of people’s living standards, people’s demand for stainless steel cabinets is constantly changing, and the rapid update and iteration of stainless steel cabinets is difficult to meet with traditional metal cutting processes. The application of fiber laser cutting stainless steel machine is just born to solve this problem, which can solve the big problem of stainless steel cabinet cutting at low cost and high efficiency. As a leading brand in the industry, BuyCNC launched the stainless steel fiber laser machine (medium-power fiber laser cutting machine), which is specialized in laser cutting stainless steel cabinets, and the pain points are tailored for the cabinet industry.

Stainless steel cabinets are becoming more and more popular

Now most companies are mainly composed of three sections: office, canteen and dormitory. In addition to the company’s requirements for the environment of the office area, the environmental requirements of the canteen cannot be ignored. Especially with the outbreak of the epidemic in the past two years, people have paid more attention to diet. In order to avoid cross-infection caused by tableware hygiene during the special period of epidemic prevention and control, everyone brought their own tableware. At the same time, many companies also placed stainless steel in the canteen. Cabinets, fiber stainless steel laser cutting machine equipment has also been accepted and adopted by more enterprises.

Why choose fiber laser cutting stainless steel machine to produce stainless steel cabinets

In the production of stainless steel cabinets, cnc fiber laser cutting machine for stainless steel is a very good choice. Because the rapid update and iteration of stainless steel cabinets is difficult to meet with traditional metal cutting processes, the application of Stainless steel fiber laser metal cutting machine is just born to solve this problem. Laser cutting stainless steel cabinets has a short beam transposition time and is easier to complete continuous processing. . The stainless steel fiber laser cutter 1530 not only has fast processing speed and high efficiency, but also can complete plate cutting of any shape without changing the mold or tool, which shortens the preparation time period. The stainless steel fiber laser metal cutting machine can realize the rational use of metal plates, automatically typesetting through the computer, without wasting any material, cutting, hollowing out, punching; round, rectangular, special-shaped, for the processing of metal cabinets and other kitchen utensils Diversified and efficient laser cutting machines are very popular among manufacturers, because stainless steel fiber laser cutter can effectively reduce the processing cost of stainless steel cabinet cutting.

Advantages of using stainless steel fiber laser machine

The functional characteristics of the stainless steel fiber laser machine are that the bed is precision machined by a large-scale gantry machining center; the internal stress of the welding bed is eliminated to the greatest extent by annealing in a large gas-fired trolley-type heat treatment furnace, so that the equipment can achieve higher precision and higher stability. Not only the bed, but also the machine tool adopts the gantry-like double rack and pinion, double servo motor transmission, high torque and high inertia output, which effectively improves the production efficiency of the equipment. The laser cutting head is equipped with automatic focusing function, which greatly shortens the perforation time compared with ordinary cutting heads, especially suitable for high-speed cutting of thicker plates; the equipment not only has perfect hardware, but also keeps pace with software, professional typesetting and nesting software and professional laser The cutting system is highly integrated, with the functions of graphic intelligent layout, automatic edge-finding cutting and sharp corner smoothing processing, which can realize high-speed blasting perforation and high-speed scanning and cutting of array graphics. At the same time, it also has the function of power failure memory; the function of back cutting; the function of automatic fault alarm and emergency shutdown; the function of automatic display of fault content.

Add Your Heading Text Here

In addition to the advantages of the stainless steel fiber laser machine control system above, the laser cutting machine also has many advantages when processing metal. Perhaps for us, the application of stainless steel laser cutting machine is broader. Because it has its own unique advantages, it is unmatched by other laser cutting machines in this respect, but for us, we need to give a better definition of stainless steel laser cutting machine. Let’s take a look at stainless steel laser cutting machine. The processing advantages and processing characteristics of the cutting machine.

Processing advantages

1. Because of non-contact processing, and the energy and moving speed of the laser beam of the fiber laser cutting machine are adjustable, various processing can be completed.

2. There is no “tool” wear during the processing, and no “cutting force” affects the workpiece.

3. The heat affected zone of the processed workpiece is small, the thermal deformation of the workpiece is small, and the subsequent processing volume is small.

4. It is easy to guide, and can complete various target transformations after focusing. It is very easy to cooperate with the numerical control system. It is an extremely sensitive cutting method for processing complex workpieces.

5. The level of automation is high, and it can be fully enclosed for processing, without pollution, and with low noise, which greatly improves the task situation of the operator.

6. The processing energy density is large, the effect time is short, the heat affected zone is small, the thermal deformation is small, and the thermal stress is small. In addition, the laser is non-mechanical contact processing, which has no mechanical stress effect on the workpiece, and is suitable for fine processing.

7. High energy density is enough to melt any metal, especially suitable for processing some materials with high hardness, high brittleness and high melting point that are difficult to process by other craftsmanship.

Processing features:

1. Burr-free cutting: high precision, high speed, narrow kerf, minimal heat-affected zone, smooth cutting surface without burrs.

2. Damage-free cutting: The laser cutting head will not contact the surface of the material and will not scratch the workpiece.

3. No mechanical deformation: The slit is the narrowest, the heat affected zone is the smallest, the local deformation of the workpiece is extremely small, and there is no mechanical deformation.

4. Arbitrary shape cutting: It has good processing flexibility, can process arbitrary graphics, and can cut pipes and other special-shaped materials.

5. Deformation-free cutting: Non-deformation cutting can be performed on materials of any hardness, such as steel plates, stainless steel, aluminum alloy plates, and hard alloys.

BuyCNC as a well-known stainless steel metal sheet fiber laser cutting machine factory in China, we have a professional fiber laser cutting stainless steel machine, which has fast cutting speed, small light spot, flat incision without protrusion, and can maintain fast cutting speed to complete the cutting job. And it can also process a variety of metals, such as carbon steel, stainless steel, aluminum alloy, brass, galvanized sheet, galvanized sheet, copper, etc. If you want to know more about this machine, please leave your message contact information.