Table of Contents

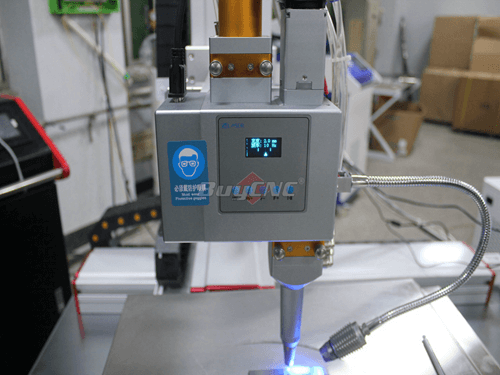

As the most popular welding machine nowadays, the handheld laser welding machine has the advantages of simple structure, quick start, flexible welding, strong welding penetration, and can be used for welding of various complex angles. outdoor welding) and stationary. It has strong expansibility, and can be equipped with manipulators or other CNC welding machines in the later stage, as well as replacing ordinary hand-held heads or swinging hand-held heads to meet various welding needs.

Handheld laser welding machines have a great tendency to replace penetration argon arc welding, electric welding and secondary welding. The models generally have two modes: continuous and pulsed, and the power range is generally between 500W and 3000W. The welding head usually has two specifications, one is the ordinary welding head and the other is the swing welding head.

Application Industry of handheld laser welding machine

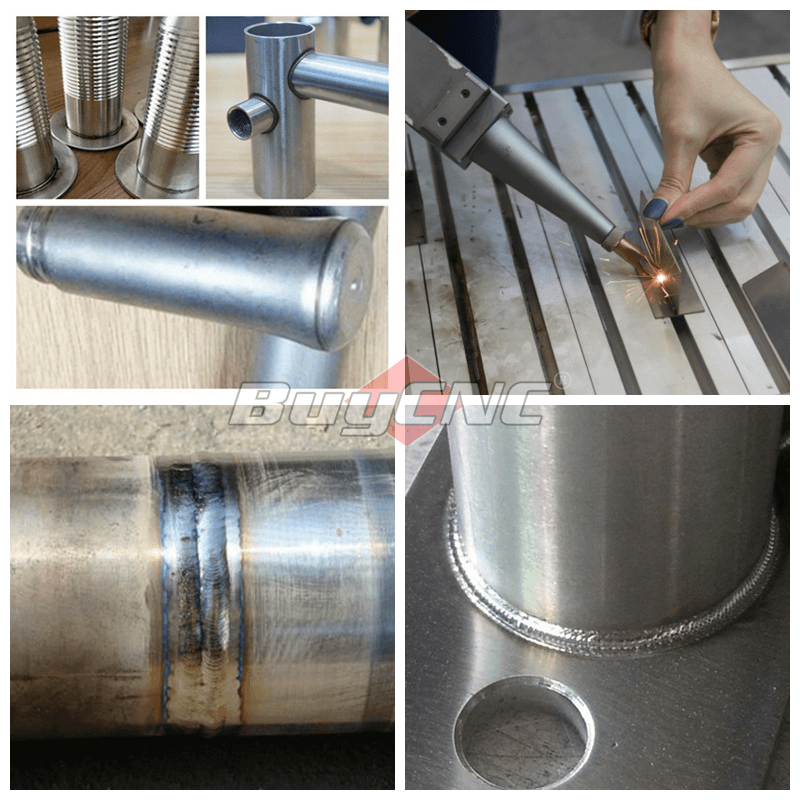

It is suitable for stainless steel, carbon steel, silicon steel sheet, copper, aluminum alloy, gold, silver, chromium, nickel, titanium, tantalum and other metals or alloys, and also for welding of various dissimilar materials. Widely used in precision instruments, electronic components, home appliances, medical equipment, mobile communications, mobile phone parts, computer casings, sinks, stainless steel kitchen and bathroom products, vacuum mugs, sensors, mold accessories, safes, distribution boxes, stainless steel products, Aluminum products, copper products, alloy materials, watch glasses, jewelry, hardware components and other industries. Typical application industries are:

1. Laser welding of sheet metal, chassis and water tank;

2. All kinds of hardware lamp laser welding;

3. Laser welding of door and window frames;

4. Laser sealing and welding of kitchen, bathroom and wash basin hardware;

5. Laser welding of billboards and advertising words.

Why Handheld Laser Welding Machine is So Popular

1. Simple operation: handheld laser welding operation does not require professional welding knowledge. The operator only needs about one hour of training to complete beautiful welding and solve the difficult problem of recruiting welders.

2. High welding efficiency: The welding speed of the product is fast, which is 5-10 times that of argon arc welding, which can save 3 welding workers on average.

3. No consumables for welding: welding can be completed without wire filling, equipped with automatic wire feeder.

4. Good welding effect: small welding affected area, no deformation, firm welding, high aspect ratio.

5. High energy efficiency conversion: The photoelectric conversion efficiency of the laser is as high as 30%, and the energy consumption is lower.

6. Convenient and flexible use: hand-held welding, free and flexible, to realize outdoor welding.

7. The welding seam does not need to be polished: continuous welding mode, beautiful welding without scars, less follow-up grinding process.

8. Wide range of applications: Applicable materials, the application range covers almost most industrial industries. It is widely used in cabinets, kitchens and bathrooms, stair elevators, shelves, ovens, stainless steel door and window guardrails, distribution boxes, stainless steel furniture, industry advertising, lighting and Complicated and irregular welding processes in industries such as sheet metal chassis machines.

Maintenance of handheld laser welding machine

Handheld laser welding machines are mainly used in the processing of stainless steel industry. With the continuous improvement of process technology, the demand for hand-held optical fiber welding machines also increases. Hand-held optical fiber welding machines have also become the standard configuration of some high-end industrial production and processing enterprises.

And all kinds of hand-held fiber optic welding machine manufacturers emerge in an endless stream, and the price of each hand-held fiber optic welding machine is also different, and some of the quality is even very different. Today, BuyCNC will share with you the 3 major inspection steps for the maintenance of the hand-held fiber optic welding machine.

Key points: The maintenance of the hand-held optical fiber welding machine must be carried out by professionals who have been systematically trained.

1. Check the circulating water

Check the conductivity of the circulating water in the hand-held fiber optic welding machine. The purity of the cooling water laser cooling technology is the key to ensure the laser output efficiency and the life of the laser condenser cavity components. During use, the conductivity of the inner circulating water should be checked once a week to ensure that Its conductivity, the deionized water in the inner circulation must be replaced once a month. Pay attention to the color change of the ion exchange column in the cooling system at any time. Once it is found that the color of the resin in the exchange column becomes dark brown or even black, the resin should be replaced immediately.

2. Check the spot

Check the handheld fiber welding machine and adjust the laser resonator equipment. Operators can often use black image paper to check the laser output spot. Once the uneven spot or energy drop is found, the resonator of the laser should be adjusted in time to ensure the output beam of the laser. quality. Debugging operators must have common sense of laser safety protection, and must wear special laser safety glasses during work. The adjustment of the laser must be carried out by specially trained personnel, otherwise other components on the optical path will be damaged due to the misalignment or polarization adjustment of the laser.

3. Check the working status

Check the optical path components of the handheld fiber optic welding machine In order to ensure that the laser hand-held fiber optic welding machine has been in a normal working state, after continuous operation or when it is stopped for a period of time, the optical path such as YAG rod, dielectric diaphragm and lens protective glass should be checked before starting the machine. Check the components in the device to make sure that the optical components are not contaminated. If there is any pollution, they should be dealt with in time to ensure that the optical components will not be damaged under strong laser irradiation.

Laser Welding Machine For Sale