CNC Router For Sale

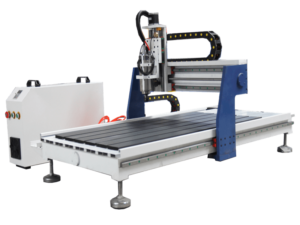

CNC Wood Router For Sale

5 Axis& 4 Axis CNC Router For Sale

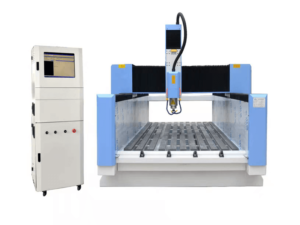

CNC Stone Router For Sale

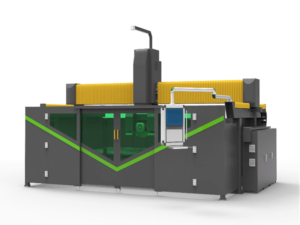

CNC Metal Router For Sale

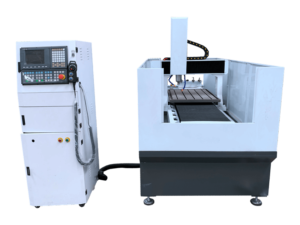

Mini CNC Router For Sale

1.What is a CNC Router? - Definition of CNC Router

The CNC router machine is the English abbreviation of Computer numerical control router machine. The CNC router machine is also called CNC engraving machine, which belongs to precision machining CNC equipment. The CNC engraving machine can be used for cutting, two-dimensional engraving, and three-dimensional engraving on various flat materials. And with the development of the engraving machine industry getting better and better, the quality requirements of the machine have also become higher and higher. Now some ordinary people can quickly master CNC router machine after simple training.

2.What Products The CNC Router Can Make? —-Aplications of A CNC Router

The Best CNC engraving router is very powerful, you can use this machine to complete a variety of materials processing. Whether it is making wooden signs, acrylic, advertising, stainless steel plates or metal engraving, this machine can easily handle it. Then I will introduce you to the related industries of CNC router machine

Woodworking industry: Cabinet doors, wooden doors, screens, wooden furniture, wood processing, craft fan windows and other products.

Mold industry:The CNC router machine can be used to engrave all kinds of reliefs, shadow engraving, open engraving, flat engraving, cutting, washing and other effects.

Advertising industry:Advertising signs, pvc boards, front plates, two-color boards, logo production, acrylic cutting, blister molding, large-character cutting, sign production, cutting PVC, crystal plates, acrylic, LED/neon grooves, hole literal cutting , Manufacture of blister light box mould.

Stone industry:Natural marble, granite, artificial stone, tombstone, milestones, ceramic tiles, glass and other materials three-dimensional relief and line carving, cutting, chamfering, drilling two-dimensional carving.

Handicraft industry:Various exquisite patterns and texts can be made on wood, bamboo, artificial marble, organic board, two-color board, crystal and other materials

Metal industry:A series of processing and cutting work can be carried out on aluminum, copper, iron, steel and other metals.

3.How To Use The CNC Router?

The CNC router machine is a precision machining equipment, so it is controlled by a computer. And the CNC engraving machine is generally used before with two software applications. They are (CAD) applications, which are mainly used to design machining paths, and the other is (CAM) applications, which are mainly used to convert the design into The machine can understand the vertical and horizontal paths. Although we can directly control the CNC router machine to process the machine through G code, it still has certain shortcomings and cannot complete relatively high-precision processing. But through the two programs of CAM/CAD, our processing range becomes larger, and we can process more precise products.

In the process of using CNC router machine, we first need to have a correct understanding and understand the general operation process. This will be of great help to users who are new to CNC equipment, so BuyCNC will outline the operation process and details. Content

1. Turn on

Before turning on the computer, first make sure that all the connections between the CNC router machine and the computer are normal, and then turn on the power of the machine and the computer. After the system is started, turn on the computer to enter the control system

2. Mechanical reset

After starting the system (before entering automatic processing, the system will determine whether the machine tool has “returned to mechanical origin”), a dialog box of “return to mechanical origin” will appear first, click the corresponding button, and the engraving machine will automatically return to the mechanical origin position, and Correct the coordinate system.

3. Check the I/O status

Check the input and output of each signal, check whether there is a fault signal, to ensure that the woodworking engraving machine machine tool can safely process.

4. Load the processing program

Before processing, the user generally needs to load the required processing program, otherwise all the functions of automatic processing are invalid.

Select [File (F)] -> [Open and Load (O)…] menu, a standard Windows file operation dialog box will pop up, and you can select the file to be processed. Or click the right mouse button in the automatic processing window to pop up a shortcut menu, select [Open and Load (O)…], and select the desired processing file in the pop-up file operation dialog box. Then, after clicking the “Open” button, the processing program is loaded into the system. At this time, you can click the “Auto” window to view the current processing program.

5. Start processing

First, place the material to be processed on the workbench of the CNC router machine, and fix the material by vacuum suction or T-slot. Check whether the material is firmly fixed. Then determine the work origin, that is, manually move the X, Y, Z, and A axis of the CNC router machine to the position of the workpiece origin desired by the user, and clear the coordinates of the current position in the coordinate window (or select [Operation (O)]->[Set the current point as the origin of the workpiece]), so that the current position will be used as the origin of the workpiece for processing when the processing program is executed.

6. CNC Tool Changing (if needed).

If you need to change the tool, then please look carefully

1. First cut off the power of CNC carving machine to make sure the machine has stopped working

2. Move the spindle to both sides of the machine to facilitate tool change

3. Fix the spindle with a tool, and use a wrench to slowly unscrew the tool

4. Clean up the impurities on the spindle and tool, and check whether the tool is intact

5. Use a wrench to install the tool, chuck and nut on the spindle, and fix the tool

6. Confirm that the tool replacement is completed, and start the CNC carving machine

7. Set the working origin again and start working.

7. Turn off CNC engraving router machine

1. Return to the mechanical origin.

2. Remove the router bit and the chuck nut is allowed to stay on the spindle.

3. Turn off the CNC carving machine kit.

4. Turn off the computer, this step can not be reversed with the previous step.

1. Move the spindle to the work origin

2. Remove the milling cutter and leave the chuck nut on the spindle.

3. Close CNC carving machine

4. Turn off the computer. Note: You cannot turn off the computer first and then shut down the device.

4.How Fast Of A CNC Router?

The processing speed of The CNC router machine is mainly determined by the power of the engraving machine spindle and the quality of the selected tool. Generally speaking, the greater the power of the spindle, the faster its cutting speed. The processing speed of the 9kw spindle is obviously greater than the processing speed of the 3.5kw spindle. The speed of most spindles is greater than about 7,000 rpm to 24,000 rpm. For the moving speed of the CNC router machine, the power of the motor is the biggest influencing factor. The higher the power of the motor, the faster the moving speed of the machine. For example, a CNC engraving machine with a 4-8N.m torque stepper motor, the machine moving speed is less than 20m/min. But if it is a CNC engraving machine with 1000w servo motor, the moving speed of the machine can be about 60m/min.

5.Are Chinese CNC Routers Good?

If it was before, I don’t know how to answer this question, but after more than ten years of rapid development, the quality of Chinese CNC router has been liked by buyers all over the world. You can buy the best CNC router at BuyCNC, because we are a CNC router supplier for about 20 years. We have a complete pre-sales and after-sales system and professional engineers, factories, etc. If you need any suggestions about CNC router machine, please feel free to contact us.

6. What size CNC router is there

The CNC Router machine has many sizes for you to choose, you need to choose the most suitable size for your work according to your needs. The most popular machines are 4x8ft CNC router machine and 5x10ft CNC router machine. These two machines can process most materials. If you want to process larger or smaller materials, we can also Your request to make CNC router machine.

The following table is the common size of the CNC Router

Inches | Feet | Millimeters(mm) |

24″x24″ | 2’x 2′ | 600×600 |

24″x36″ | 2’x 3′ | 600×900 |

24″x48″ | 2’x 4′ | 600×1200 |

48″x48″ | 4’x 4′ | 1200×1200 |

48″x72″ | 4’x 6′ | 1200×1800 |

48″x96″ | 4’x 8′ | 1300×2500 |

60″x120″ | 5’x 10′ | 1500×3000 |

72″x144″ | 6’x 12′ | 2000×4000 |

Custom made | Any size | Any size |

7.How Much Does A CNC Router Cost?

As a high-tech product, The CNC router machine is relatively expensive. However, the price of the machine is also related to the accessories of the machine itself. The main components that affect the price of the machine are: the main shaft of the machine, the motor, the workbench (vacuum workbench or T-slot workbench), the drive system, the transmission system, and the operating system. , The frame of the machine (steel or iron), etc. And the price of the machine is also related to the manufacturer, because different manufacturers will provide different machines and pre-sales and after-sales services, which will help you to use the machine more easily. Another point is that different countries have different tax rates and shipping costs for CNC engraving machines, and these factors will affect the final price of the machine. BuyCNC, as a leading CNC router machine supplier in China, we will provide you with the best quality machines and services. Most of our machines are in the price range of 2500$-20000$. If you want to buy a CNC router machine in China, then please contact us for a quote. We will recommend the most suitable product for you according to your relevant needs.

Price Range of CNC Router

Types | Minimum Price | Maximum Price | Average Price |

CNC Wood Routers | $2,300 | $35,000 | $5,500 |

CNC Stone Routers | $5,500 | $38,000 | $6,500 |

CNC Metal Routers | $5,000 | $30,000 | $7,500 |

CNC Foam Routers | $7,000 | $25,000 | $12,000 |

3 Axis CNC Routers | $2,300 | $35,000 | $5,500 |

4th Axis (Rotary Axis)CNC Routers | $5,000 | $12,000 | $7,000 |

4 Axis CNC Routers | $18,000 | $32,000 | $23,000 |

5 Axis CNC Routers | $70,000 | $200,000 | $85,000 |

8.Maintenance Guide for the CNC Router

After you have a CNC router machine, if you want to use it for a long time, then you must do a good job of maintenance. BuyCNC, as a supplier with CNC router machine industry for more than 20 years, we have organized how to deal with CNC router The machine performs high-quality maintenance. Then BuyCNC will introduce you how to do routine maintenance and regular maintenance of CNC carving machine.

1. Maintain the spindle and motor

As one of the most important parts of CNC engraving machine, the spindle must be maintained well. Because it is the most vulnerable component. First of all, we need to check the lubrication system of the spindle regularly, and add lubricating fluid or oil and gas lubricating oil in time. Avoid spindle damage caused by too little lubricating fluid. Then check the cooling system of the spindle regularly. At present, there are two main cooling systems for the spindle, one is the air-cooled spindle and the other is the water-cooled spindle. The air-cooled spindle needs to check the spindle fan regularly, and the water-cooled spindle needs to check the coolant regularly. The state and capacity of the system and add coolant in time. Finally, the material must be processed strictly according to the power of the spindle, and a low-power spindle cannot be used to process hard materials.

2. Clean up the dust in time

When the CNC engraving machine is working, it will generate a lot of dust. If you have purchased a dust removal system, then you can quickly clean the dust. But some dust will fall into the transmission system and CNC control box of the machine, and this dust needs to be cleaned every day. When we clean up these dusts, we need to pay attention. First, cut off the power supply. We can clean up after the machine is turned off. We need to open the CNC control box and use a brush to clean the wires in the machine, because too much dust will cause the wire joints. Catch fire. If your CNC router machine is also equipped with a computer, you also need to clean the computer.

3. Maintain the transmission system

If we want CNC carving router machine to work normally, then we need a transmission system that can work stably. The transmission system of the CNC router machine mainly includes ball screws and guide rails, racks and so on. These drive system components of BuyCNC are all high-quality components of well-known brands with long service life and low failure rate. However, we still need to perform routine maintenance on it. When the machine is finished, we need to carefully clean the dust on the transmission system. If your CNC engraving machine is equipped with an automatic oil pump, it will automatically refuel the transmission system to keep it lubricated. Status. If you use manual lubrication, then you must manually lubricate the ball screws, guide rails, racks, etc. at least once every 3 days.

4. Maintain the motor

At present, there are mainly three types of motors for CNC engraving machines, namely: servo motors, stepping motors and hybrid servo motors. We need to do a good job in the maintenance of these motors in order to make the machine have a longer service life. First of all, clean up the dust and oil on the motor regularly, and then check whether the cooling fan of the motor is working normally and whether the motor makes an abnormal sound. If any abnormality is found, the machine needs to be shut down in time, processed, and repaired. Good to return to normal use later to avoid more serious consequences. It should also be noted that the motor should be placed in a clean, open place to avoid damage to the exterior of the motor.

Customer reviews and testimonials of CNC router machine

1. Ben George

From the United States

Sep. 27, 2021

I want to operate a CNC machine shop, mainly for the CNC routing service. Many customers around me need 3d CNC routing service. Thank you the seller for giving me many free 3d dxf files for the CNC machine. So far, I have done many cool CNC machine projects.

2.John David

From Australia

Sep. 26, 2021

I searched on Google for what can you make with a CNC wood router, and got to know that a CNC wood router can be used to make guitars. My daughter is learning guitar, so I want to make a guitar for my daughter herself. The seller has free CNC wood router machine files for making guitar and also taught me how to program a CNC wood router. I am now looking for CNC wood router projects that make money to make some pocket money.

3. Martin

From the United States

Sep. 25, 2021

I have around $5000 budget for buying a new CNC desktop router, which is not enough to buy an American-made CNC machine. So I choose a CNC router China-made, but with the HSD brand best CNC machine engraving spindle. The noise of the machine is not big, it seems good till now.

4. Fernandez Lee

From Spanish

Sep. 24, 2021

I read some CNC metal router buying guides and decided to buy a ball screw CNC router. Because ball screw CNC router base is iron cast, which is with high precision. The CNC routing table is very hard, so it is not only a CNC router for plastic but also for metal.

5. Brown James

From the United States

Sep. 11, 2021

This CNC machine system is very easy to use, and it is quick to learn. The CNC machine tutorial helped me a lot.

6.Steven Jacob

From Canada

Sep. 8, 2021

I have a manual router, but it can’t perform 3D carving, so I bought this 3d CNC cut router, which is completely automatic. I have experimented with many CNC carving router project plans on this CNC carving machine, which is much more enjoyable than my old manual router. The seller also gave me the CNC machine feeds and speeds calculator so that I can experiment before actually carving patterns, which is very convenient.

7.Paul Smith

From UK

Sep. 3, 2021

The main thing to make with the CNC machines for us is logo making. the CNC signs making router machine is easy to use.

8. Ivanov, Ivanovic

From Russia

Sep. 1, 2021

It is my first personal CNC machine, I watched many CNC router’s Youtube videos and came across some high-quality videos made by BuyCNC, many of the videos are about CNC machine training and teach how to use a CNC engraving machine. I am very worried about what should I do if I don’t know how to use a CNC router? Supplier’s CNC router training video allows me to eliminate this worry. The seller also asked me to download CNC machine software free online, I have installed it on my computer, and it is very easy to use. If I change to a large CNC machine in the future, I will still buy it from BuyCNC.

9. Mr.David Muller

From Germany

Aug. 20, 2021

I have some good CNC router business ideas and want to implement them, so I bought this CNC routing machine. I think I’m talented, and I learned CNC router programs soon, and the next step is to buy suitable CNC router tools and router bits.

10.Boller Josh

From Netherlands

Aug. 8, 2021

This CNC wood router is great, we have already done many work with this 4×8-foot CNC wood router machine, and I am starting to make money!

11. Jean Martin

From Bulgaria

Jul. 15, 2021

My studio needs a CNC 3d router to perform CNC work such as 3d CNC routing and CNC 3d carving. So I bought this custom CNC 3d router. Keeping the studio clean is very important to me, so I also purchased an additional dust collector for the CNC router. I am very satisfied with this precision CNC router.

12. Dirk Schia

From Germany

Jul. 2, 2021

It is impossible if you buy a 4×8 CNC cheap router made in the USA within a budget of $5,500USD. I googled CNC router comparison and compared some CNC machine manufacturers in the USA, such as Legacy, Techno, Laguna. Legacy woodworking CNC seems good to me, but my budget is not enough. So I have to choose the CNC Router China made. My bottom line is that the software for the CNC metal routers must be American and easy to use. Fortunately, I found it on BuyCNC.

13. ALAN Partenl

From France

Jun. 12, 2021

This is my first CNC wood machine. It is better than I expected. The CNC wood router machine for wood looks very solid.

14. Luska

From Estonia

Jun. 1, 2021

The packaging of the CNC carving machine is very good. I have opened the packaging. The CNC carving router machine is in good condition. I mainly do CNC 3d carving, so I asked for some CNC 3d router files from the seller and installed CNC carving software with the seller’s support. The seller also recommended the water-cooled spindle— the best CNC carving router spindle for wood carving, which has a better cooling effect than the air-cooled spindle. If you want to buy a CNC wood carving router machine, I recommend BuyCNC to you.

15. Mark Bowen

From Australia

May. 18, 2021

I use this CNC milling router machine to do many CNC 3d carving work. Although it is only an entry-level CNC mill router, it has helped me realize many CNC wood router projects ideas.

16. Tomas Jackie

From United States

May. 3, 2021

The reason I wrote this CNC router review is that I was really surprised! The seller gave me many free things—–free CNC machine control software, free dxf files, CNC router plans free, free CNC router bits for plastic, free CNC machine projects, free SVG files and so on. Buying things in China is really cost-effective and can save many money. I now find out CNC mill router projects that make money.

17. Marco Ashamed

From Italy

Feb. 23, 2021

I am a sign maker, and I need to import an affordable CNC signs router machine. I mainly use this machine for custom CNC routing, such as CNC routing signs, CNC routing acrylic. This is a simple CNC 3 axis router, but It is also a smart CNC router.

18. Smith Davie

From United States

Feb. 6, 2021

The engineer taught me how to use a CNC router and how to modify gcode for the CNC router. He gave me some CNC router project files to experiment with, and now CNC 3d router working is not difficult for me.

19. Deric kevin

From Canada

Jan. 8, 2021

I own a guitar studio, mainly to teach others to play guitar. I know that many students want a custom guitar. I found many CNC hobby router supplies online and asked them about CNC wood router guitar-making machines. Among these CNC wood machine supplies, BuyCNC responded most professionally and quickly. So I ordered this custom CNC guitar-making machine. Now I have learned how to CNC routing guitar.

20. Julies Irving

From Chile

Sep. 14, 2020

I checked the CNC carving router comparison online, and I found that different CNC carving router supplies quoted CNC mill router prices are quite different. I know I need a CNC router basics model,Professional stepper motor, Mach3 controller is ok for me.

21. Richard Jeff

From Poland

Sep. 1, 2020

The seller gave me some free CNC table router clamps and CNC router bits for plastic. My CNC carving machine is very worth the price.

22. Jacob Keller

From United States

Dec. 19, 2020

My family runs a clock factory. I used to make clocks by hand, but the labor is too expensive, so I looked for a CNC metal router clock-making machine. This CNC metal router is indeed very efficient.

23. Martin Park

From France

Sep. 12, 2020

Recently, I sold my second-hand American-made CNC engraving router, because I need a stable commercial CNC engraving router to make a cabinet, and a high precision CNC wood engraving router. I read many Chinese CNC router reviews and finally chose BUYCNC. I like my new CNC wood engraving Router.

24. Farahat

From UAE

Sep. 1, 2020

I bought this CNC 4 axis router from BuyCNC in February. I am very happy that the rotary axis for the CNC router is a four-jaw chuck. I have many friends who bought Chinese CNC milling routers, and most of the CNC machine companies in China provide three-jaw chuck. The four-jaw chuck is easier to clamp the wood.

25. Gary Jeff

From the U.K

Aug. 17, 2020

The price of this 3d wood carving machine is within my budget, and the seller also gave me many CNC routing tools, CNC files and many accessories, thanks!

26. Lopez Kevin

From Spain

Aug. 2, 2020

I think I bought the best CNC carving router within my budget, and the service of the CNC router machine is very satisfactory to me!

27. Maslo Sergei

From Russia

Jul. 12, 2020

I read a many comparisons between China CNC mill router and CNC mill machine manufacturers USA on the CNC router forum, and I finally chose the China CNC router. I have been using this China CNC router now, and I can feel that the China CNC router has made great progress in recent years, with faster speed and lower noise.

28. Daniel Steven

From France

Jul. 12, 2020

I downloaded CNC machine software in advance, and the seller sent me a CNC carving router feeds and speeds chart. I tried a lot of plans. The purpose of writing the reviews is to tell everyone that the machine is good and you can buy it with confidence.

29. Edward Keller

From UK

Jul. 5, 2020

I know that there are many different CNC router classes. The CNC engraving machine prices are also different. I want to choose a large CNC router, but my garage does not have such a large space to store it. So I bought this small CNC engraver kit.

30. Carter Henry

From United States

Jun. 19, 2020

I bought a custom CNC router. The advantage of buying a China CNC router is that I can customize the size I need. This CNC routing machine is a qualified CNC router artwork-making machine.

31. Noel Nick

From Belarus

Jun. 19, 2020

This 3d carving machine is also called 3d CNC routing machine, which is very popular in our country. I have used it to replace manual work.

32. Paul Steve

From Spain

Jun. 2, 2020

I bought a simple CNC router for beginners, and I have a small CNC router shop, mainly for 3d CNC routing. There are many 3d CNC routers for sale online, and the CNC router machine price is very different. I finally chose this 3d CNC router lathe. I look forward to receiving it soon.

33. Philip Nicholas

From UK

Jun. 2, 2020

I bought a multi-spindle CNC router, I know that CNC router spindles are very important for CNC router machines, so I chose the best CNC router spindle.

34. Oliver Joe

From United States

May. 28, 2020

The CNC carver is working well in my workshop, I really like it!

35. Louis Lacque

From France

May. 05, 2020

I chose CNC router manufacturers very seriously. Before buying, I searched for CNC router youtube on Youtube, read many Chinese CNC router reviews, and knew many router brands. Through Google CNC router comparison, I finally chose BuyCNC.

36. Joe Josh

From United State

Mar. 05, 2020

I want to buy an affordable CNC router machine, so the price of an American-made CNC router is unrealistic for me. and the Chinese CNC machine is not bad, so I finally chose to buy a Chinese CNC router.

37. Martinez Jack

From Belarus

Feb. 19, 2020

Because CNC router manufacturers USA do not support custom CNC routers, so I have to buy a China CNC router. I do guitar and mass production, so the efficiency of the machine is very important to me. This CNC router guitar-making machine I bought is of good quality and high efficiency.

38. Simmons Ben

From Australia

Jun. 2, 2020

I want to start my advertising sign-making business, so I need to import CNC signs making router machine. The main job of this job will be the CNC routing sign. I am looking forward to my new business.

39. Thompson Jee

From Canada

Jun. 2, 2020

This CNC carving router machine is good for CNC 3d carving. I have used the electric wood carving machine to make some cool CNC router projects.

40. John Smith

From United States

May. 28, 2020

I bought the CNC sign making router processing machine for CNC routing signs. Routing CNC is easy to operate.

41. Mark Morris

From France

May. 05, 2020

The CNC mill router machine is good, who can tell me the CNC machine bits for sale

42. David Besman

From Germany

Apr. 11, 2020

I did many homework for the CNC machine comparison. There are many CNC milling router manufacturers all over the world, including CNC router manufacturers in the USA, China, Italy, etc.

43. Steve Eric

From United State

Mar. 05, 2020

The CNC router carving machine is solid,good!

44. The most suitable CNC router for you is the best CNC router.

45. I plan to buy a CNC engraver since last year. I have been contacting BuyCNC for more than a year, and now I finally bought it.

46. I bought a CNC for beginners, I don’t need an industrial CNC router, so I chose an entry-level CNC machine, only spend $2800USD.

47. My CNC router cost is not too much, but the quality of the router machine is good.

48. For this expensive CNC router, I don’t have high expectations, I just need it to be able to do simple 3D work.

49. There are many engraving machines for sale. I chose a 3d engraving machine. I hope it will not lose steps because the materials I use are very expensive, and I don’t want to waste my materials.

50. This router engraving machine is the best CNC router for beginners, its size is small, only 4×3, but it has as many functions as an expensive one.

51. This 3d wood carving machine looks very solid, and my wife and I couldn’t lift it. If you want to buy this 3d wood carving machine, we recommend that you choose the machine with wheels, which are more convenient to move.

52. My son needs a clock, so I used my CNC router engraver to make him a clock. He likes it very much, and he is very interested in this CNC engraver machine. I have already started to teach him how to operate the machine.

53. If you are looking for a CNC router machine for sale in the market, I recommend BuyCNC.

54. This engraver CNC is the same as I imagined, with high precision and a good appearance.

55. I don’t know who the Chinese best CNC router supplier is, I just happened to see the engraving machine for sale on the seller’s website. Before buying, I consulted the seller and tell the supplier I want an entry-level CNC machine. The seller told me that 6090 is the best CNC router for beginners.

56. I am a furniture maker. I need to process 100 sheets every day. I know the task is very heavy. The supplier recommended me a heavy-duty industrial CNC router. Although I can only process about 80 sheets a day, I am still very satisfied because the machine is very stable and precise.

57. I saw in a CNC forum that some guy recommended this 3d engraving machine. It is a CNC for beginners. This CNC router costs only $3,000 USD.

58. My daughter’s teacher often asks to make some crafts. I bought this machine and have already made some crafts. Her teacher is very satisfied with them.

59. Just now, the freight forwarder informed me that my router engraving machine will arrive at the port today, and I am looking forward to its arrival.

60.Obviously, my manual wood router can no longer meet my needs. I need a 3d wood carving machine. This expensive CNC router I chose is a small one with a working size of 600x400mm.

61. You may see a lot of CNC router machines for sale, but choosing one that suits you is not easy and it is very time-consuming.

62. Before purchasing, I checked more than 100 related articles of CNC router engraver in detail, and the CNC engraver machine I finally bought fully met my requirements.

63. The seller taught me how to run this engraver CNC router, and I think I should try to increase its speed.

64. When I received this 3d engraving machine, to be honest, I didn’t know how to use it. I tried to contact the supplier and the technicians patiently taught me how to use the machine step by step. I connected the water pump, the vacuum pump, turned on the machine, and learned how to make a simple design. Thanks to much for the supplier’s help. In my heart, BuyCNC is the best CNC router, supplier. If you are also looking for the best CNC router for beginners, I strongly recommend BuyCNC.

65. I bought a 2mx3m industrial CNC router. When I unpacked the package, the gantry of the machine was removed. The seller told me that because the width of the container was not enough, the gantry was removed to reduce the width. The seller sent me the installation video, and I installed the gantry myself. Of course, it took me almost half a day.

66. I bought an additional wireless handwheel for my router engraving machine. It is very convenient to use, especially when setting the router bit.

67. I can not afford an expensive CNC router, so I bought the machine from China.

68. The operating system I chose is Mach3, this system can be connected to a computer, and the operation is more valuable.

69.I want to process aluminum, so I want a water-cooled spindle. I think the cooling effect should be better.

70. I bought an entry-level CNC machine. There are free router bits and tool collets in the accessory box from the seller for testing the machine.

71. The screw CNC engraver has only three motors, but the rack and pinion CNC router engraver have four motors, and the rack and pinion CNC router engraver is more powerful.

72. The seller supply Vectric Aspire for free, and I am very happy to buy this 3d wood carving machine.

73. My ground is not level. Fortunately, the seller gave me the leveling base. I never expected this inexpensive CNC router to have so many accessories.

74. I added extra pop-up pins to my CNC engraver machine.

75. CNC router cost is very different, my budget is about 10,000 US dollars, so I chose an ATC CNC router.

76. In the beginning, I didn’t even know what TT payment meant. The seller gave me step by steps how to pay and clear customs. If you are also interested in engraver CNC, you can ask me if you have any questions.

77. Buying Chinese CNC for beginners is a good choice, at least the price is not expensive, and the machine is fairly stable.

78. On the market, most of the engraving machines for sale are from China, and the CNC router machine for sale in Jinan is very famous.