Table of Contents

The CNC router furniture manufacturing machines basically refer to computer numerically controlled machine tools used to manufacture all kinds of furniture. This CNC router machine helps to manufacture furniture products with various functions. For example, doors, windows, tables, chairs, cabinets, stair railings, office furniture, etc. If there is no CNC router furniture making machine, then you cannot shape the wooden structure and make all kinds of furniture products suitable for home and office environments. Currently, there are many types of furniture manufacturing machines on the market. These CNC router machines have many easy-to-use functions that can help your factory to improve the production speed and product quality to a large extent. With the right CNC router furniture making machine, you can also get great profits.

Serval CNC Router Furniture Making Machine

Next, we will introduce you to several most popular CNC router furniture making machines, and recommend BuyCNC’s best-selling wood CNC router machine.

1.Wood CNC Router Furniture Making Machine

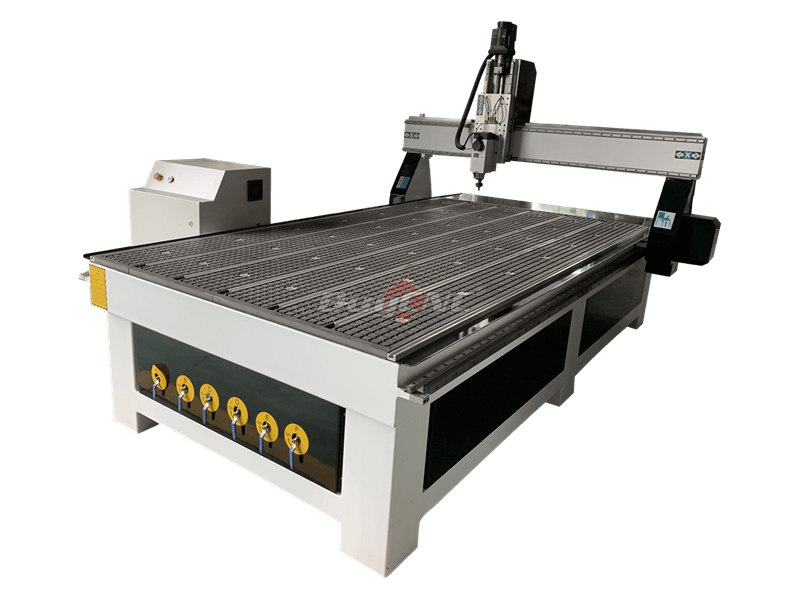

In the current furniture industry, The CNC wood router machine is the most commonly used CNC router furniture manufacturing machine in the world. This CNC router furniture making machine uses a computer program to control the machine to produce furniture. The CNC router machine also brings higher work efficiency and product quality. Therefore, it provides higher accuracy than traditional furniture production tools. CNC router planer is an indispensable machine for almost all furniture manufacturers. CNC machine with different configurations can realize various furniture manufacturing processes. For example, cutting, engraving, drilling, milling, etc. So next, I would like to introduce a CNC router furniture making machine suitable for carving complex 3D patterns or cylindrical furniture parts.

This is One of the best CNC wood router Woodworking machine,it’s spindle is HQD air cooling spindle.Which can process wood, as well as chipboard, medium density fiberboard, plastic, acrylic glass and other high quality used for furniture, doors etc. This CNC milling machine for sale is popular in many fields, please contact us if you want it.

2.4 Axis CNC Woodworking Engraving Machine

As the name suggests, the four-axis wood furniture machine can be processed on four-axis. Generally, this furniture making machine is divided into two models. One is a real 4 axis CNC milling machine, which has a spindle that can rotate 180° from left to right. Therefore, it can be carved on wood from multiple directions, or grooved or drilled on the side of the board. Therefore, the wooden furniture machine can make 3D patterns. The other is a CNC milling machine with a rotating device. Engraving on cylindrical furniture is very convenient. For example, table legs, handrails, uprights, uprights, etc. Therefore, the four-axis CNC milling machine has a wide range of applications in the manufacture of traditional or complex style furniture.

The 4 axis CNC router machine for wood with with Linear ATC system is an economical processing center.It adopts the a 9KW(12HP) high frequency automatic tool changer spindle with 8-position tool rack, pneumatically retractable vacuum hood and multi-zone vacuum t -slot table. This makes this CNC router machine for sale can process wood, MDF, chipboard and many other different materials. Now This CNC router price is on discount, please contact us if you need it.

3.Wood Nesting CNC Machine

Wood nesting CNC machines are similar to CNC milling machines, and this nesting CNC machine is also one of the most commonly used furniture manufacturing machines in the industry. The nested CNC machine tool is the most suitable cutting machine for processing panel furniture and custom furniture.But unlike CNC milling machines, CNC nesting furniture machines can perform long-term cutting operations. Many furniture manufacturing factories use CNC nested furniture machines to cut and drill cabinet products. For example, kitchen cabinets, wardrobes, closets, shelves, cabinets, etc. The main difference between the CNC milling machine and the nested CNC milling machine is that the CNC milling machine is mainly used to engrave patterns on furniture panels, but it is not suitable for a large amount of cutting work. The nested CNC machine tool is mainly used for cutting panel furniture and can cut for a long time. If you have enough budget, you can also add other functions to the nested CNC furniture making machine. For example, automatic labeling, automatic loading and unloading platforms, etc.

The heady-duty APS-PG series CNC Router is specifically for the batch-cutting of cabinets door in the home kitchen decoration industry. This Cabinet CNC Machine offers precision and high-speed cutting of wood, MDF, chipboard and other materials. Also, have the function of cutting and nesting.

4.Multi-Process Nested CNC Furniture Manufacturing Machine

Multi-process nested CNC machine tools mainly include double-process nested CNC machine tools, three-process nested CNC machine tools and four-process nested CNC machine tools. According to the number of processes, the nested CNC furniture making machine can be equipped with different spindle motors. Each spindle can carry a tool, so when you need a knife, the corresponding spindle will automatically lower to work. The remaining spindles will stop running and enter the standby state, eliminating the need for manual tool replacement. Therefore, the four-process nested CNC furniture manufacturing machine can realize up to four processes. Very suitable for the production of cabinets and cabinet doors. In addition, you can replace a spindle of this cabinet maker with a drilling kit to perform drilling operations. In this case, the multi-process nested CNC cabinet making machine can meet most of the cutting, engraving and vertical drilling needs in furniture making. It greatly saves time and labor.

As a professional woodworking CNC router with vacuum table machine, this machine body is welded by thick steel pipes, so it is enough strong to process different materials. And it has many advanced kit such as Hiwin linear rails and bearings, Germany precision helical racks on the X and Y axes etc. It is worth mentioning that the powerful CNC vacuum pump of the CNC router for sale machine can vacuum the material within 3 seconds. This greatly improves the work efficiency of woodworking CNC router machine.

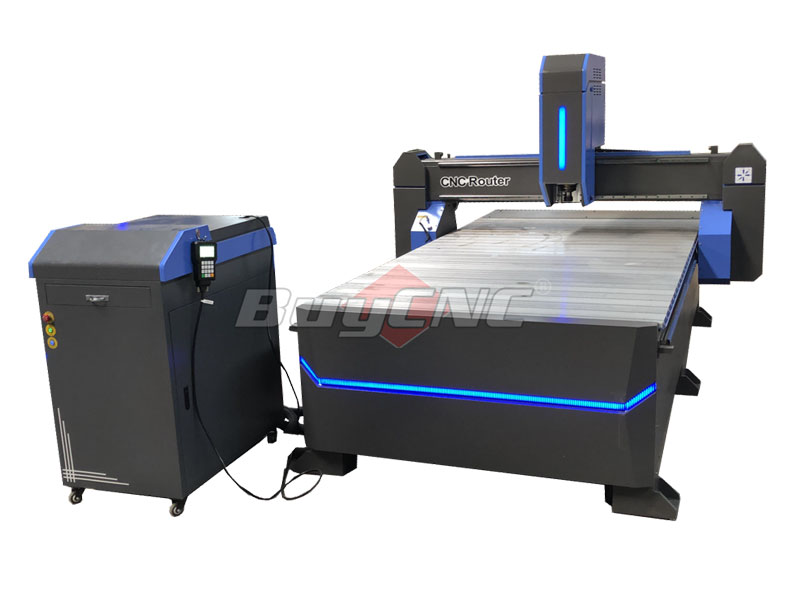

5.Linear ATC CNC Milling Machine Machining Center

The disadvantage of multi-head nested CNC machine tools is that the number of installed spindles is limited. Therefore, the technology that can be realized by the machine is also limited. If you need more processing in furniture manufacturing, you can choose a linear ATC CNC router. Compared with the multi-head nested CNC furniture machine, it is an advanced furniture manufacturing machine. Such a machining center has a linear tool magazine that can accommodate more than 8 tools. So it can realize more than 8 processes.

As a professional woodworking CNC router with vacuum table machine, this machine body is welded by thick steel pipes, so it is enough strong to process different materials. And it has many advanced kit such as Hiwin linear rails and bearings, Germany precision helical racks on the X and Y axes etc. It is worth mentioning that the powerful CNC vacuum pump of the CNC router for sale machine can vacuum the material within 3 seconds. This greatly improves the work efficiency of woodworking CNC router machine.

In addition to the most commonly used furniture making machines mentioned above, there are many small CNC router machines or auxiliary furniture making machines. For example, sliding table saws, profile trimming machines, hinge drills, CNC wood polishing machines, etc.

These CNC wood router machines can perform various functions, such as cutting, grooving, rounding corners, drilling holes in hinges, polishing, etc. All these auxiliary furniture manufacturing machines can be used individually or together in a furniture production line. The use of these furniture making machines greatly improves furniture production efficiency and saves labor and time. The price of this auxiliary furniture making machine is cheaper than the aforementioned furniture machine. This makes them very cost-effective.

Advantages of CNC Router Machine

1. The CNC machine has an exquisite woodcarving structure, which helps to achieve accuracy and speed.

2. The CNC machine is equipped with a vacuum suction table, which is designed for easier and more effective wood carving crafts. Therefore, the products can be processed more conveniently, and workpieces of different shapes can be cut.

3. CNC wood milling machine can help operators save time and production costs. It has dual-station equipment designed to maximize production efficiency. Woodworking machinery not only improves production efficiency, but also guarantees product quality.

Several Simple CNC Router Projects

1. Bookshelf

The most commonly used type of wooden furniture for CNC engraving machines is shelves. Whether it’s a small or large bookshelf, you can use this powerful tool to design and build. Determine the material and program the shelf unit. An amazing fact about using this tool is that you can do other chores around the store, while at the same time cutting the parts on the shelf. Once the blocks are assembled, you can decorate them to your liking.

2. Table

Place a coffee table to make your home comfortable and stylish. But this time, you don’t need to buy a new one. If you have a CNC wood milling machine at home, please design your own coffee table. First, you need to find quality wood materials. Second, continue with the digital design process, and then simply import the files into the system. For many amateurs, this is the most interesting part of the process. While running the machine, you can complete the steps of cutting and painting or dyeing.

3. Cabinet

Use the CNC router to build the cabinet. First, just put the wood of your choice on the workbench. Use software to create a cabinet design. Although this is the longest part, it is the most critical step in the process. If you already have experience with this procedure, you can complete it in 10 minutes or more. Then, import the design file into the system to start the CNC machine tool.

Conclusion Of CNC Router Furniture Making Machine

For those who want to engage in the furniture manufacturing industry, The CNC router furniture manufacturing machine is definitely a worthwhile investment. Whether it is a furniture manufacturing machine or a complete furniture production line, it can greatly improve efficiency and save furniture manufacturing Time and labor . In addition, due to the high degree of automation and simple operation, one person can operate 2-3 machines at the same time. This also helps to improve production efficiency. The finished furniture has many characteristics, such as high precision, novel style , durability, etc.

BuyCNC provide a variety of wood CNC router furniture making machine, if you want to buy a production furniture, then we will recommend the most cost-effective CNC router machine for you, and provide you with the most comprehensive pre-sales and after-sales service. If you want to know more about CNC router furniture making machine, please leave your contact information.