CNC Router Tips

What is CNC Router Machine

With the rapid development of high-tech technology, The CNC router machine has also developed steadily and rapidly. The CNC is an abbreviation for computer numerical control, and the CNC router machine is a machine tool used for carving, cutting and other operations. It supports cutting or engraving wood, stone, plastic, etc. in multiple dimensions through computer-operated cutting tools. The CNC router machine is the crystallization of precision technology, we can use it to complete a variety of precision machining. But as a CNC router machine, we must master certain tips when using the CNC router machine, in order to better play the CNC router The ability of the machine.

Maintenance measures of wood CNC engraving machine

1. First check the spindle and cooling water of the engraving machine

2. Turn on the spindle at low speed and run idling for 5 minutes;

3. If the machine tool has not been running for a long time, it should be run-in with the full stroke first, and the run-in time should be about half an hour.

4. The continuous running time of CNC router machine should not exceed 8 hours a day, so as to ensure the normal operation of the circulation system and cooling system. The cooling water should be replaced regularly to prevent the water temperature from becoming too high. If the temperature of the working environment in winter is too low, you can use antifreeze to replace the water in the water tank.

5. After the machine work is completed, clean up the machine’s processing table and lubrication system, X, Y, and Z axis to avoid dust accumulation.

Wood CNC Router Tips

Next, in order to improve the engraving quality of CNC router machine, we provide you with a few tips.

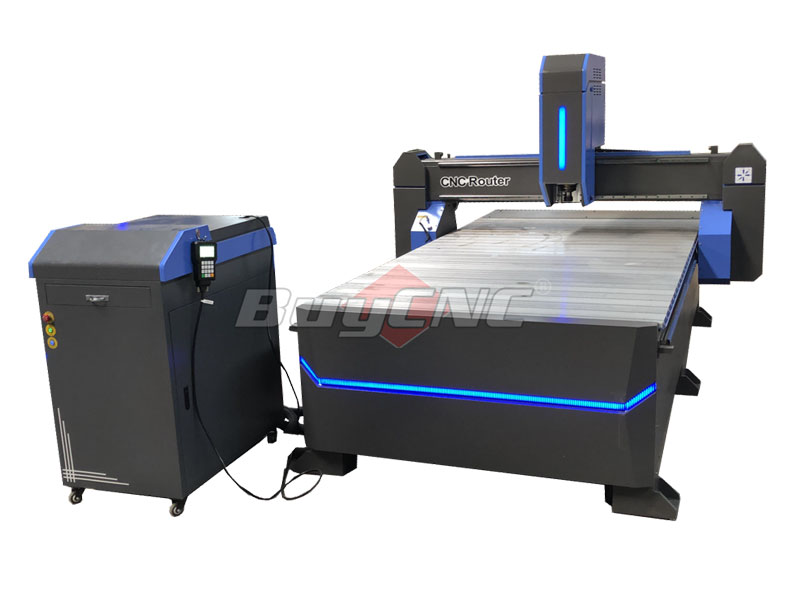

As a professional woodworking CNC router with vacuum table machine, this machine body is welded by thick steel pipes, so it is enough strong to process different materials. And it has many advanced kit such as Hiwin linear rails and bearings, Germany precision helical racks on the X and Y axes etc. It is worth mentioning that the powerful CNC vacuum pump of the CNC router for sale machine can vacuum the material within 3 seconds. This greatly improves the work efficiency of woodworking CNC router machine.

Stone CNC Router Tips

What is the stone CNC router

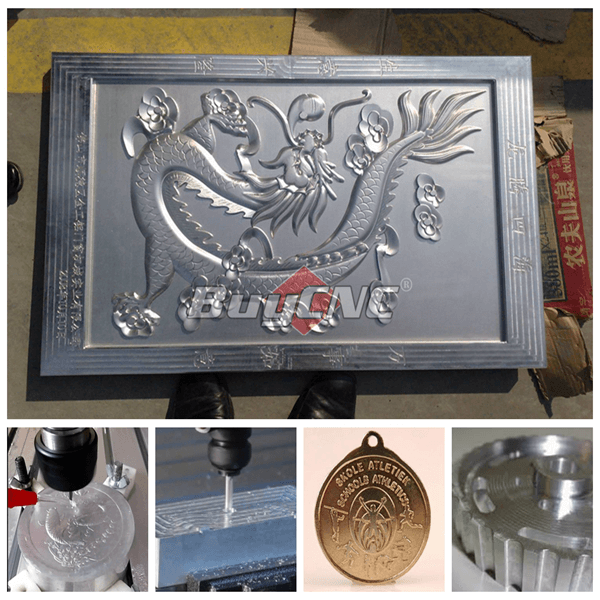

The Stone CNC milling machine is a fully automatic CNC machine tool, designed for deep processing of quartz stone, marble, granite, artificial stone, granite, slate and other stone countertops, which can realize drilling, milling, grinding and cutting functions.

The main functions of the stone engraving machine: The stone engraving machine can be used for three-dimensional relief, sharp-bottomed carving, flat-bottomed carving, line carving, chamfering, drilling, etc.

This is the latest black single-head CNC stone router machine. It has strong performance and can handle most of the stone. At the same time, the Z axis has been upgraded. This marble engraving machine has a Z axis of 500mm high and with high wall on the two sides of the work table, which can effectively prevent stone debris from flying away. At the same time, you can also choose different worktable sizes. We now have two commonly used sizes: 1300x2500x500mm/1500x3000x500mm.

The Important Tips About Stone CNC Router

1. We must regularly check whether the water circulation system and the lubrication device system can operate normally, especially in cold winters. In order to avoid freezing of the circulation system, we need to replace the antifreeze in time. So that the stone cnc router machine can operate normally.

2. Pay attention to the temperature of the spindle. Because the stone is relatively hard, the temperature of the spindle for processing the stone is generally very high. If the spindle of the stone engraving machine is not equipped with a circulating cooling device, the spindle will be damaged due to excessive temperature. On the one hand, we can add new cold water to the water tank to ensure the temperature of the spindle through normal water circulation. On the other hand, it can also be equipped with a separate water cooler to ensure that the temperature of the spindle will not be too high.

3. In order to ensure safety when using stone cnc router, we need to ensure that the machine has a good grounding, reduce static electricity generation, and improve the stability of the cnc router machine.

Metal CNC Router Tips

When people mention CNC engraving machines, most of us would think of cutting and engraving wood on such machines. However, CNC notching machine can also be used for materials such as aluminum, brass and copper.But when we use metal CNC router to process metal, we need to pay attention to the following requirements.

The Tips about metal CNC router

1. Be patient-CNC Router Tips

Because the CNC milling machine can cut aluminum, this does not mean that you can machine major aerospace parts, such as wing spars. You need to slow down to succeed. You do not need to reduce the speed and feed rate, but the speed of material removal will greatly reduce the speed that can be achieved by a dedicated CNC milling machine. So we have to be patient

2. Use a professional calculator to calculate speed and feed-CNC Router Tips

When cutting metal with CNC router machine, the machining limit of CNC router machine may be reached. In order to avoid damaging the workpiece and the machine, we need to use a professional speed and feed calculator to set the correct value.

3. Use smaller diameter tools-CNC Router Tips

When cutting metal, we need to increase the RPM. Using a tool with a smaller diameter is a way to increase the RPM. You can choose a ½ inch end mill, but the best option is to reduce it to ¼ inch or less. When you want to use a smaller diameter tool, you need a rigid tool so that the deflection of the tool will not cause you any trouble.

4. Pay close attention to the cutting depth-CNC Router Tips

We should pay close attention to the cutting depth when processing metal, because the deeper the depth, the more difficult it is to clean. But if you use a material with a thin aluminum layer, you only need to place the thin plate with the aluminum side up. This will help you quickly remove the aluminum from the cutter and you can continue to work.

As a professional woodworking CNC router with vacuum table machine, this machine body is welded by thick steel pipes, so it is enough strong to process different materials. And it has many advanced kit such as Hiwin linear rails and bearings, Germany precision helical racks on the X and Y axes etc. It is worth mentioning that the powerful CNC vacuum pump of the CNC router for sale machine can vacuum the material within 3 seconds. This greatly improves the work efficiency of woodworking CNC router machine.

Jinan BuyCNC CNC router machine supplier can provide you with the most comprehensive service, if you want to know more about CNC router machine or want to be able to get help from our professional engineers, then please leave your contact information, we are happy to help you.