Table of Contents

What should we know before use stone CNC router

The stone CNC router is a large-scale mechanical equipment that can carry out three-dimensional calligraphy and painting, graphic carving, cutting, lettering and other processes on natural stone, glass, and ceramics. This stone router machine is suitable for stone industry, stone monument processing industry, artistic relief, Buddha statues, and advertising industries. , Decoration industry, ceramic industry, glass processing industry.

As CNC router stone engraving machine is more and more widely used, people have higher and higher requirements for its performance and operating speed. So how should we make reasonable use of stone engraving machine to work for us?

First of all, we need to conduct perfect theoretical and practical training before using stone CNC router, and we can conduct practical training only after passing the theoretical examination. In this way, the phenomenon of operating errors will be reduced as much as possible during the stone carving process. In actual operation training, training on engraving tools is also required.

Secondly, we need to train engineers on all kinds of stone knowledge, including the application range, thickness, hardness, carving size, etc. of the stone. Familiar with the carving methods of different stones.

Finally, there is software operation training. The software used by different Stone CNC engraving machines will be different. After passing the theoretical and practical operation training, software training should be carried out, including typesetting, operation, path generation, etc., to avoid wrong operations.

This is the latest black single-head CNC stone router machine. It has strong performance and can handle most of the stone. At the same time, the Z axis has been upgraded. This marble engraving machine has a Z axis of 500mm high and with high wall on the two sides of the work table, which can effectively prevent stone debris from flying away. At the same time, you can also choose different worktable sizes. We now have two commonly used sizes: 1300x2500x500mm/1500x3000x500mm. If you want to know about more information about 3d stone carving machine for sale, please contact us.

Applicable materials for The Stone CNC cutting router

1. Marble: Among personalized carvings, marble is the most ideal raw material of choice. The texture of marble is good and the color is solemn. Whether it is dark black, jet black, dark green, rose or gray, it gives people a very elegant beauty. . Therefore, on the basis of having many traditional products, it has recently developed to use laser technology to engrave photos, images and texts, which is quite popular.

2. Granite: The texture is very hard, wear-resistant and durable, and is widely used in prizes, souvenirs and construction. Granite belongs to the limestone system. Its obvious characteristic is that it has spots, the color and luster give people the appearance of “salt and pepper”, and some also have the texture of marble. Granite can accept various polishing and finishing treatments. In view of the many colors of granite, especially black and white granite is often used to engrave text, images, etc., the carved products have a strong visual effect and are very eye-catching.

3. Artificial marble: Artificial marble is made of natural marble or granite crushed stone as filler, cement, gypsum and unsaturated polyester resin as adhesive, and it is made after stirring, forming, grinding and polishing. Artificial stone has the following characteristics: light weight, high strength, corrosion resistance, pollution resistance, convenient construction, and its carved patterns can be controlled by humans. It is an ideal decorative material for modern buildings.

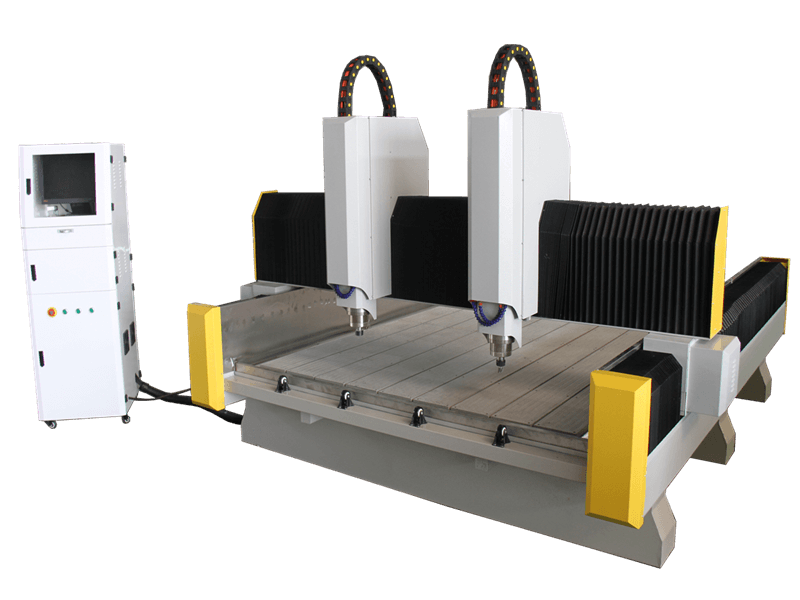

This is a 2 head stone CNC router machine, and this CNC stone router machine is very cheap. This stone engraving machine is more efficient than ordinary machines. Stone CNC engraving machine can carry out 3D relief engraving on most of the stone, as well as line engraving, chamfering, drilling 2D engraving and other processing methods. If you need a two-head engraving machine, then this machine is a great choice.

Features of The CNC stone engraving router

1. BuyCNC’s stone CNC router machine adopts a thick-walled all-steel structure design. After welding and tempering aging treatment, it has strong rigidity, strong strength and stable rotation, so that it will not be deformed or shaken during long-term high-speed operation.

2. Gantry type movement, fixed work surface, can process the material on the work surface at will;

3. The countertop adopts vacuum adsorption countertop, which is made of bakelite, which is resistant to high temperature and corrosion. The adsorption countertop is designed according to customer needs, and the non-metallic materials of different sizes of plates are strongly adsorbed;

4. A professional equipment with high comprehensive cost performance, suitable for medium and large furniture wooden door enterprises, suitable for batch, all-weather work, standard 4.5KW air-cooled high-power electric spindle, original high-precision imported bearings, greatly extending service life .

5. Adopt Taiwan AMT high-precision, zero-clearance square weighted sliding linear guide pair. The rack system is a high-precision special craft rack, which runs smoothly and has high precision; and the Y axis adopts bilateral drive, fast speed, high efficiency, and load-bearing capacity. Large, heavy cutting can be performed.

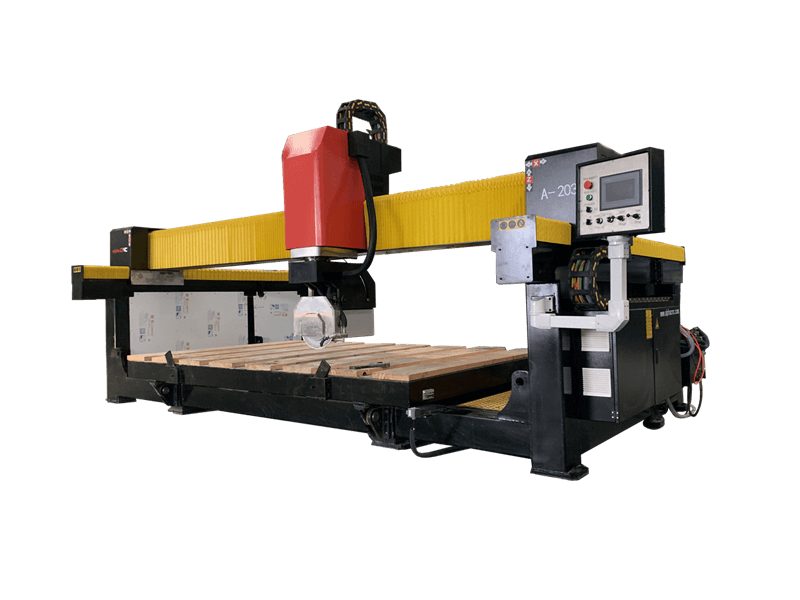

This is a 3 axis CNC bridge cutting saw machine,it is designed for stone company,this marble cutting machine can meet the diversified processing needs of the stone market.

Compared with traditional infrared bridge CNC saw machine, our stone slab cutting machine has advanced servo motor and hydraulic turning table (maximum turning 85°). Not only that, this granite cutting tools also supports Vertical 90° cutting and 45° angle cutting, chamfering.

Processing technology of stone engraving machine

1. Flat carving: Flat carving is basically carving on the stone. The image is carved out and the picture is recessed. Flat sculpture is basically painted on a flat medium (such as slate, tile), and there is basically no real sculpture, so it is also called “imaginary color”.

Ping carving, the carved pattern must maintain a certain height and depth with the surface of the carving. There are two types of flat carving: inverted and positively carved: dig out the pattern part so that the displayed pattern is lower than the surface of the ground. This practice is called inverted carving. For example, the ring line of the core plate of the cabinet door, the skirt plate on the plaque seat, and the draped teeth are mostly flat-carved techniques, and most of the sun patterns are used. The intaglio technique is not used much on furniture.

2. Relief: Relief is two-dimensional, the image is kept, and the rest is removed, the picture is protruding on the object.

relief sculpture is a kind of sculpture. The sculptor sculpts the image he wants to shape on a flat plate, so that it is out of the plane of the original material. Relief is the product of the combination of sculpture and painting. It uses compression to deal with objects, uses perspective and other factors to express three-dimensional space, and only allows one or two sides to view it. Reliefs are generally attached to another plane, so they are used more in architecture and can often be seen on utensils. Due to its compression characteristics, it occupies a small space, so it is suitable for decoration in a variety of environments.

Relief is a semi-three-dimensional sculpture that is embossed on the surface of the stone in the shape of an image (just the opposite of sinking). According to the different depth of the image modeling, it can be divided into bas-relief and high-relief. The bas-relief is a single-level statue with a single content; the high-relief is a multi-level statue with a more complicated content. The carving technique and performance style of relief sculpture are basically the same as that of round sculpture. Many large-scale monumental buildings, high-end mansions, and private houses in ancient and modern times are equipped with such decorations. Their main works are wall plugs, flower windows and dragon pillars (early) and pillar foundations.

3. Round sculpture: The round sculpture is also called the three-dimensional sculpture, which is the overall expression of art on the sculpture. The viewer can see all sides of the object from different angles. It requires the sculptor to sculpt in all directions from front, back, left, right, top, middle, and bottom. Round sculpture works, also known as three-dimensional sculptures, refer to non-compressed three-dimensional sculptures that can be appreciated from multiple directions and angles.

There are also various techniques and forms of round sculptures, including realistic and decorative, concrete and abstract, indoor and outdoor, rack and large-scale city sculptures, colored and non-colored, etc.; sculpture content The subject matter is also rich and colorful. It can be characters, animals, or even still life. The materials are even more colorful, including stone, wood, metal, clay sculpture, plaster, textile, paper, plants, rubber, and so on. It is mostly used in fountains or gardens and indoors.

4. Shadow sculpture: Shadow sculpture, as the name suggests, its sculpture image is lifelike, just like photography. It is a new technology developed and innovated based on the needle black and white technology in the early years. On a bluestone plate that is only 1.5 cm thick and polished, it uses a variety of micro steel solders of different thicknesses, depending on the size of the lead point, The organic combination of depth, thickness, density and virtual reality are carefully carved and imaged accordingly.

The shadow sculpture is made of pure-color stone such as black jade and Shanxi black. After being polished by water, the outline of the image to be carved is drawn on the polished surface. According to the principle of black and white light and shade imaging, a special needle-like small alloy steel head tool is used. The wrist force adjusts the thickness, depth, and dotted lines of the needle points to express the image. Shadow sculpture not only has the same artistic effect as photographic optics, but also embodies the brushstroke technique of painting, which has a unique artistic charm. In today’s day and night of modern science and technology, Dadian stone carving shadow carving, as a traditional hand-carved handicraft, has more and more demonstrated its value, and it has overcome the shortcomings of yellowing and fading of photographs and pictures, and can be preserved forever.

The CNC 5 axis bridge cutting machine is a cost-effective stone processing machine tailor-made for the majority of stone companies in order to meet the diversified processing needs of the market. This 5 axis granite cutting machine is a multifunctional CNC stone router machine, it can process almost all stone.