Table of Contents

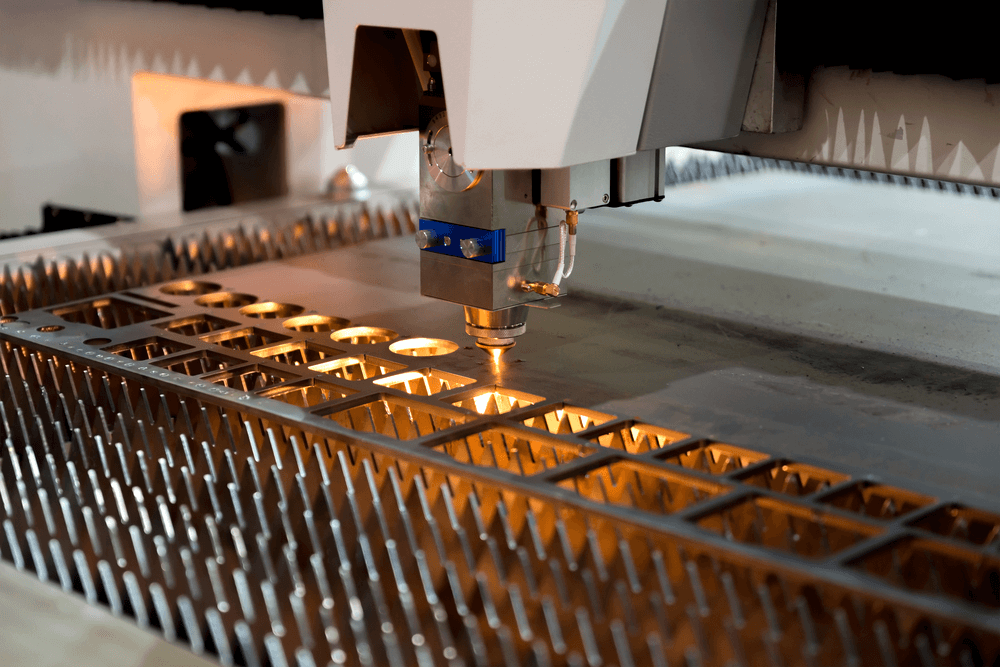

The laser cutting machine uses a focused high-power density laser beam to irradiate the workpiece to rapidly melt, ablate or reach the ignition point of the irradiated material. cut open. Laser cutting is one of the thermal cutting methods. The upper limit of the cutting thickness of laser cutting machines with different powers is different. In theory, the higher the power of the laser cutting machine, the better, but there are more reasonable choices in practical applications. For example, high-power laser cutting is used for cutting metal sheets. The laser cutting machine is obviously not a particularly economical method. The following is an analysis of the cutting thickness of laser cutting machines with different powers, including stainless steel, carbon steel, alloy steel, aluminum plate, silver, copper, titanium and other metal materials. And when the laser cutting machine cuts metal plates of different thicknesses, what is its performance? Next, please follow BuyCNC to understand the specific performance of laser cutting machines cutting metals of different thicknesses.

Laser cutting machine for cutting thin sheet metal

Sheet is a material often used in traditional industries, and this material has been widely used in many fields. However, in the cutting of thin plates, such problems are often encountered. For example, the toughness of thin plates is very poor. In the process of cutting with traditional mechanical cutting machines, the phenomenon of thin plates often occurs, and even the surface of thin plates will appear. The problem of cracking and blistering, now a new type of laser technology can cut the thin plate freely without touching the surface of the thin plate, without any damage to the surface of the thin plate. This kind of sheet metal laser cutting machine has been widely used in the field of sheet metal cutting.

The thin plate laser cutting machine is mainly suitable for cutting some thin plates of various non-metallic and metal materials. Now some pipes of this material can also be cut by this machine. Of course, in addition to this, holes and other hollowing treatments can also be performed on these metal materials. Such a multi-functional mechanical steel processor is also irreplaceable by many other products. For example, thin aluminum plates, thin zinc plates, etc., which are more common in the metal market, can be cut by this machine with a thickness of less than three millimeters. There are also non-metallic materials such as ceramic sheets that are more common in the market. Non-contact punching and cutting with a laser cutter.

There are two types of thin plate laser cutting machines in the laser market, one is a cutting machine with relatively low efficiency, and the other is a cutting machine with relatively high efficiency. The scope of application of these two cutting machines is also different. For example, the general cutting machine with relatively low power is more suitable for cutting some small-sized metal products, and it is used for a long time during the cutting process. Tasks with relatively low cutting requirements can use this cutting machine for cutting. However, some imported cutting machines with relatively high power on the market generally have an advantage in this efficiency. This type of cutting machine is more suitable for cutting some large-format materials. On the other hand, this kind of machine is often used for cutting products that require relatively high cutting accuracy.

Above we have introduced the basic performance of thin plate laser cutting machine and its practical application range. Different types of cutting machines are suitable for different types of cutting requirements. The actual needs of people cutting are different, we can choose different types of products according to our actual situation. Of course, when choosing different types of cutting machines, our own actual economic situation is also.

Laser cutting machine for cutting medium and thick metal plates

Today, with the rapid development of laser cutting machine manufacturing technology and the continuous improvement of the level of numerical control technology, the market application of fiber laser processing equipment in metal sheet cutting is rapidly being applied. Not only thin plates, but even medium and thick metal plates, laser cutting machines can cut them, but when cutting medium and thick metal plates, it is inevitably more difficult to cut than thin plates.

With the development of laser cutting machines and technology updates faster and faster, many users encounter many problems when cutting thick plates. According to the market feedback information, the thickness of the sheet, the cutting quality and the selling price of the cutting equipment subdivide the market application group of sheet metal processing, especially the small and medium-sized users in this field urgently need to cut the thickness range of the metal sheet, and the cutting quality is good. Power fiber laser cutting machine complete set of processing equipment. So what are the difficulties of the laser cutting machine when cutting thick plates?

The kerf is too narrow, resulting in increased heat loss. The reduction in cutting speed increases the heat loss in the cutting area. The main form of heat loss is heat conduction. The greater the thickness, the greater the heat conduction loss and the lower the cutting speed.

Material removal at the bottom of the cut became inconsistent, and although the laser penetrated the slab, a large amount of slag stuck to the bottom. The formation of dross is caused by the low average cutting temperature at the bottom of the incision, which is also due to the large energy loss, and the quality of the incision in this case is usually not high.

Fiber lasers have a small spot diameter and limited depth of focus. Fiber laser cutting machine can maintain a high laser power density in the depth of cut when cutting metal medium and thick plates, but due to the small beam diameter and thin slit, it is not conducive to cutting and slag removal. This puts forward higher requirements for the mode, beam dispersion, collimation, shaping and scope of the fiber laser, and also brings greater difficulty to the process quality of fiber laser cutting of medium and thick metal plates.

The role and influence of auxiliary gas mass and air pressure. Take oxygen as an example; oxygen plays a very important role in fiber laser cutting of carbon steel medium and thick plates. The laser is incident on the surface of the workpiece to form small holes. When the laser beam moves along the cutting direction, there are oxide melts around the small holes and the slit. The purity and pressure of oxygen have a great influence on laser cutting. Oxygen with a lot of impurities and inappropriate air pressure cannot provide enough energy to form a highly fluid melt at the bottom of the incision, thus reducing the cutting quality and cutting speed.

By measuring the quality and pressure of the auxiliary gas at different slit positions, it is found that the narrower the slit, the worse the effect of the auxiliary gas, and the more difficult it is to maintain the cutting quality. The effect on cut quality is heavy. The difference in geometry reduces the quality of the inflection point cut. When laser cutting thick plates, the inclination angle of the melting front becomes prominent, which will lead to the reduction of the material’s absorption coefficient of the laser light, thereby ensuring the cutting quality by increasing the cutting power and reducing the cutting speed.

Compared with other metal cutting machines, the laser cutting machine has its unique advantages. The laser cutting machine will be widely used in the cutting field due to its high spot conversion rate, high cutting precision, flexible processing ability, good cutting quality and adaptability. For a wider range of applications, whether it is a medium-thick metal plate or a thin plate, the laser cutting machine can cut it perfectly.

Fiber laser cutting machine cutting material and thickness comparison

For different metal materials, the cutting thickness of different power laser cutting machines has a great relationship with the cutting materials. 500W fiber laser cutting machine, 1000W fiber laser cutting machine, 2000W fiber laser cutting machine, 3000W fiber laser cutting machine, etc. How thick can laser cutting machines of various powers cut?

Generally speaking, the thickness limit values of different laser cutting machines for cutting various materials are as follows (for reference only, the actual cutting ability is also related to the quality of the cutting machine, cutting environment, auxiliary gas, cutting speed and other factors):

1. The 500W fiber laser cutting machine has a particularly large thickness for cutting different materials: carbon steel is particularly thick 6mm; stainless steel is particularly thick 3mm; aluminum plate is particularly thick 2mm; copper plate is particularly thick 2mm

2. The 1000W fiber laser cutting machine can cut different materials with a special thickness: carbon steel with a special thickness of 10mm; stainless steel with a special thickness of 5mm; aluminum plate with a special thickness of 3mm; copper plate with a special thickness of 3mm

3. The 2000W fiber laser cutting machine can cut different materials with a particularly large thickness: carbon steel with a particularly large thickness of 16mm; stainless steel with a particularly large thickness of 8mm; aluminum plate with a particularly large thickness of 5mm; copper plate with a particularly large thickness of 5mm

4. The 3000W fiber laser cutting machine can cut different materials with a particularly large thickness: carbon steel with a particularly large thickness of 20mm; stainless steel with a particularly large thickness of 10mm; aluminum plate with a particularly large thickness of 8mm; copper plate with a particularly large thickness of 8mm

5. The 4500W laser cutting stainless steel is particularly large 20mm, but the quality of the cutting surface above 12mm is not good, so it is definitely a bright surface cutting below 12mm. The 6000W cutting capacity will be better, but the price is also higher.

In the process of practical application, the cutting ability of fiber laser cutting machine is also related to various factors such as the quality of the cutting machine, laser type, cutting environment, cutting speed, etc. The use of auxiliary gas can also improve a certain cutting ability, so there is no absolute The standard judges its cutting thickness. For example, the cutting of carbon steel mainly relies on oxygen combustion, and the cutting of two stainless steel mainly depends on power. Generally, a 1000w fiber laser cutting machine can cut carbon steel plates with a thickness of about 10mm. It is slightly difficult to cut stainless steel plates. To increase the cutting thickness, it is at the expense of the edge effect and speed.