Popular Laser Stainless Cutting Machine

Table of Contents

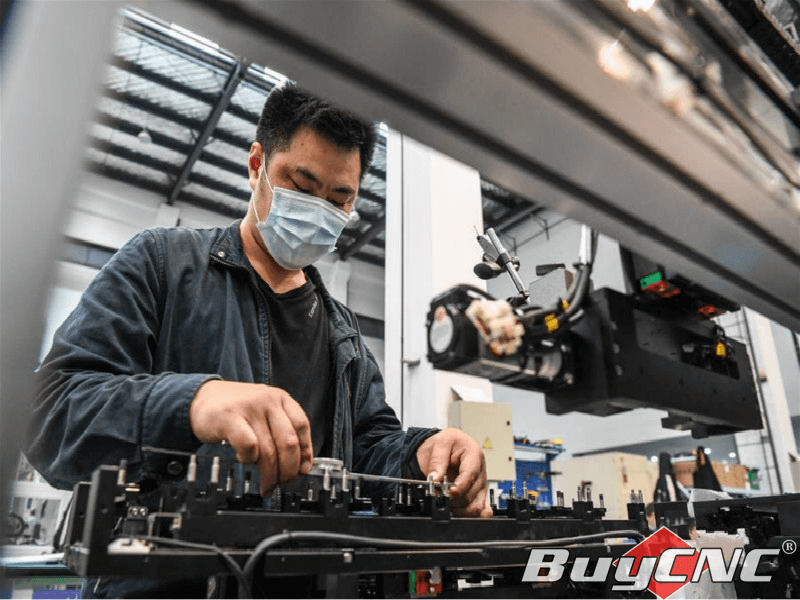

Maintain The Laser Stainless Cut Machine

The stable and normal operation of the laser stainless steel cutting machines is inseparable from the usual correct operation and daily maintenance.Therefore, in order to ensure the normal operation of the machine, we need to carefully maintain the stainless laser cutting machine. Next, BuyCNC will introduce how to maintain the stainless laser cutting machine.

1. Water replacement and water tank cleaning

Because the function of the water cooler is to reduce the temperature of the laser generator and prevent the laser from being burned out.So we have to frequently replace the cooling water and clean the water tank.

Note: Before the machine works, make sure that the laser tube is filled with circulating water.

The water quality and temperature of the circulating water directly affect the service life of the laser tube. It is recommended to use pure water and keep the water temperature below 35°C. If it exceeds 35°C, the circulating water needs to be replaced, or ice cubes are added to the water to reduce the water temperature (it is recommended that the user choose a water cooler or use two water tanks).

Clean the water tank: first turn off the power, unplug the water inlet pipe, let the water in the laser tube automatically flow into the water tank, open the water tank, take out the water pump, and remove the dirt on the water pump . Clean the water tank, replace the circulating water, restore the water pump back to the water tank, insert the water pipe connected to the water pump into the water inlet, and arrange all joints. Power on the water pump alone and run it for 2-3 minutes (make the laser tube full of circulating water).

2. Cleaning of the fan

The main function of the fan is to remove the smoke from the cutting, to ensure that the workshop air is clean, and to prevent the smoke from contaminating the lens. Therefore, in order not to affect the laser stainless steel cutter machines in normal use, we need to clean up the Fan.

The long-term use of the fan will accumulate a lot of solid dust in the fan, make the fan generate a lot of noise, and it is not conducive to exhaust and deodorization. When the fan suction is insufficient and the smoke exhaust is not smooth, first turn off the power, remove the air inlet and outlet pipes on the fan, remove the dust inside, then turn the fan upside down, and pull the fan blades inside until it is clean, and then install the fan.

3. Cleaning the guide rail

Guide rail and linear shaft are one of the core components of the laser stainless steel cutting machines, and its function is to play a guiding and supporting role. In order to ensure the high processing accuracy of the stainless laser cutting machine, the guide rails and straight lines are required to have high guiding accuracy and good movement stability.

During the operation of the stainless laser cutting machine, due to the large amount of corrosive dust and smoke generated during the processing of the processed parts, these smoke and dust will be deposited on the surface of the guide rail and linear shaft for a long time, which has a great impact on the processing accuracy of the equipment, and will Corrosion points are formed on the surface of the linear axis of the guide rail, which shortens the service life of the laser stainless steel cutter.

In order to make the stainless laser cutting machine work normally and stably and ensure the processing quality of the products, the daily maintenance of the guide rail and linear axis must be done carefully. (It is recommended to clean once every half month and shut down operation) (It is recommended to clean before work every day, and the equipment must be shut down) (It is recommended to clean the water tank and replace the circulating water once a week).

4. Fastening of screws and couplings

After the motion system has been working for a period of time, the screws and couplings at the motion connection will loosen, which will affect the smoothness of the mechanical motion. Therefore, during the operation of the stainless steel cutter machine, observe whether there are abnormal noises or abnormal phenomena in the transmission components, and find problems in time. Sturdy and maintained. At the same time, the machine should use tools to tighten the screws one by one after a period of time. The first firming should be about one month after the stainless steel cutter machines is used.

5. Inspection of optical path

The optical path system of the stainless laser cutting machine is completed by the reflection of the mirror and the focusing of the focusing mirror. In the optical path, the focusing mirror does not have an offset problem, but the three mirrors are fixed by the mechanical part, and the possibility of offset is relatively high. Large, although there will be no deviation under normal circumstances, it is recommended that the user check whether the optical path is normal before each work.

6.Daily maintenance of laser stainless steel cutting machines

1).Inspection of laser working gas and cutting gas: check the gas cylinder of laser working gas

2).Check that the cooling water pressure is maintained between 3.5 and 5 Bar.

3).Check the temperature of the cooling water, the temperature of the water required by the selected laser is better.

4).Check the oil level in the laser vacuum pump. If it is not enough, add it.

5).Check whether the laser oil circuit, water circuit, and gas circuit are leaking, and whether the pneumatic components and pipe joints of the vacuum pump and resonant cavity are leaking.

How to Maintain Laser Stainless Steel Cutter

In addition to the daily maintenance of the stainless steel cutting machines, in order to keep the stainless steel cutting machine in a good working condition, we also need to carry out a series of maintenance work on the machine, such as replacing parts.

1.How to install or replace the optical lens of the laser cutting machine

Before installing the optical lens, please pay attention: wear clean, clean your hands with soap or detergent, and wear white clean and light gloves; it is strictly forbidden to touch the lens with any part of your hand; when taking the lens, you should wear gloves and Take the side of the lens and do not directly touch the coating surface of the lens.

When assembling the lens, do not blow into the lens with your mouth; the lens should be placed on a clean table with a few pieces of lens paper underneath. When taking the lens, you should be careful to prevent bruises and falls, and do not apply any force on the coating surface of the lens; the lens holder where the lens is installed should be clean, and a clean air spray gun should be used to clean the dust and dirt in the lens holder Then, take out the lens and gently put it into the lens holder.When installing the lens to the lens holder, do not use too much force to fix the lens, so as not to deform the lens and affect the quality of the beam.

2. Steps of laser stainless steel cutting machine to clean the lens

Different lenses have different cleaning methods. When the mirror surface is flat and there is no lens holder, use lens paper to clean, such as cleaning the mirror; when the mirror surface is curved or the mirror surface has a lens holder, you should use a cotton swab to clean, such as cleaning the focusing lens.

Steps to clean the lens with lens paper: Use a blowing balloon to blow off the dust on the surface of the lens; clean the surface of the lens with alcohol or lens paper. Do not use dry lens paper to drag directly on the lens surface, but place the lens paper flat.

Put 2 to 3 drops of high-purity alcohol or high-purity acetone on the surface of the lens, and slowly pull out the lens paper horizontally toward the operator. Repeat the above actions several times until the mirror surface is clean; if the mirror surface is very dirty, Fold the lens paper in half 2 to 3 times and repeat the above steps until the mirror surface is clean.This can increase the service life of laser stainless steel cutting machines

Steps to clean the lens with a cotton swab: first use a spray gun to blow off the dust on the mirror surface; then use a clean cotton swab to remove the dirt; use a new cotton swab moistened with high-purity alcohol or acetone to move in a circular motion from the center of the lens to scrub the lens. After wiping for a week, change to another clean cotton swab and repeat the above operation until the lens is clean.

Never use cotton swabs that have already been used for operation; clean the lens with a clean cloth to remove the residual marks on the mirror surface, and be careful not to Scratch the mirror surface; take the cleaned lens to a place with sufficient light to observe. If the reflection of the lens is good, it indicates that the lens has been cleaned.This can reduce the failure rate of the stainless laser cutting machine.

BuyCNC is famous for its high-quality laser stainless steel cutting machines. We will provide customers with professional maintenance advice and maintenance methods. This makes our machines have a longer service life and a lower failure rate. If you want to buy a cheap high-quality laser stainless steel cutting machines, please contact us.

Related Blogs About Laser Cutter Machine

The Complete Guide to CNC Woodworking Machines: Revolutionizing the Woodworking Industry

Table

The Ultimate Guide to CNC Wood Routers: Everything You Need to Know

Table