Table of Contents

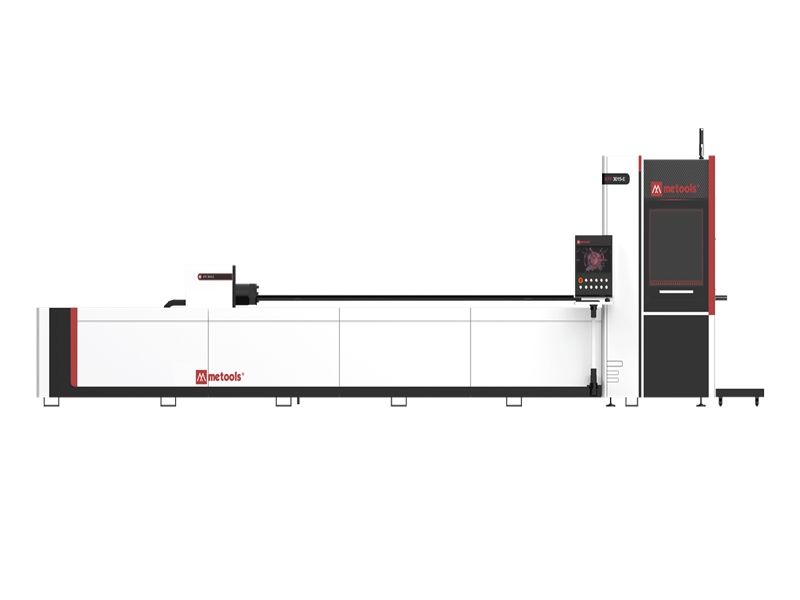

What is fiber pipe laser cutter

As an advanced metal processing method, laser cutting technology has been used in more and more different fields of metal cutting machines. The fiber pipe laser cutter we will introduce today is one of them. The metal pipe fiber laser Cutting machine is a machine that uses laser cutting technology to cut metal materials. It mainly processes metal round tubes, square tubes, rectangular tubes, channel steel and other materials. Metal and other materials can be cut seamlessly with the best fiber laser pipe cutting machine. Once the machine is programmed, it can be widely used for custom cutting jobs.

The basis of laser tube cutting is the laser beam. Lasers are differentiated by wavelength. Because they can carry a large amount of information, there is no electromagnetic interference, and there is no signal leakage, so they are usually used in communication engineering. When applied to metal cutting, the advantages of its high energy density and narrow beam are reflected.

One of the biggest benefits of using china fiber laser pipe cutting machine is that it can make complex cuts faster compared to other machines. For example, punching and cutting various graphics on pipes of various shapes and sizes. In addition, the fiber pipe laser cutter can provide a good cutting section, and no secondary treatment is required for subsequent welding and other processing, which is equally applicable to the cutting of thin-walled and thick-walled pipes. The real difference of laser pipe cutting is the cutting precision. Due to the improvement of fiber pipe laser cutter, the industrial application of metal pipe has been developed rapidly.

Metal pipe fiber laser cutting machine is widely used in Doors and windows industry

Doors and windows are an indispensable part of the real estate industry. With the rapid development of real estate in recent decades, it has also driven the rapid development of the upstream and downstream of the real estate industry chain. There is a huge demand in the door and window industry, which has higher requirements for the processing efficiency and quality of door and window products. It is said that one out of every three door and window cutting manufacturers is using a metal pipe fiber laser cutting machine.

The metal pipe fiber laser cutting machine is a high-tech product integrating laser cutting, precision machinery, numerical control technology and other disciplines. It can realize a series of functions such as automatic bundling and feeding, CCD pipe section identification system, pipe floating trusteeship mechanism, automatic sorting and unloading of finished pipe fittings, intelligent remote monitoring, and automatic measurement of tube sheet length.

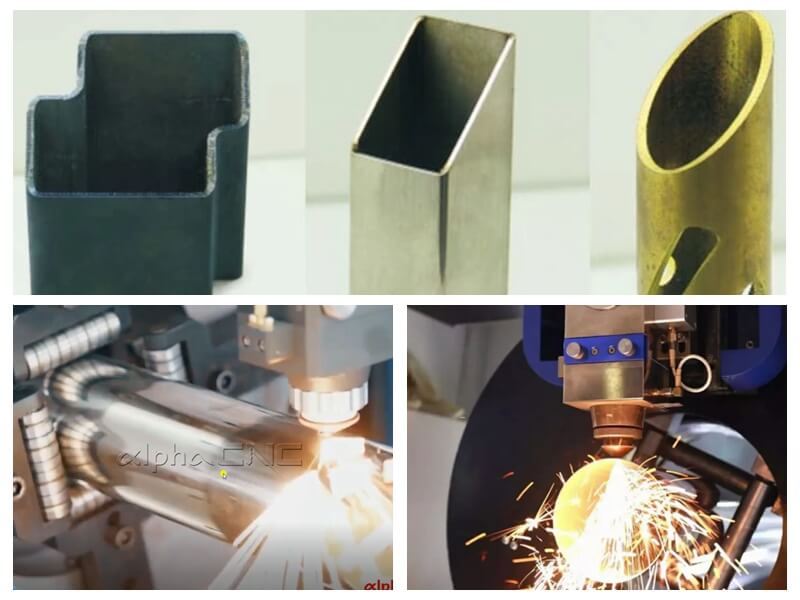

In the cutting of doors and windows, there are many pipes such as square pipes, rectangular pipes, round pipes, elliptical pipes and special-shaped pipes, and tubular profiles such as angle steel, channel steel, I-beam, T-beam, etc., which are all suitable for best fiber laser pipe cutting machine, and More than enough, at the same time, the materials that can be processed by the tube laser tube cutting machine include carbon steel pipes, stainless steel pipes, aluminum alloy pipes, copper alloy pipes, titanium alloy pipes and other metal pipe materials.

In addition, the pipes used in the door and window industry are various and have different diameters. In addition to fully automatic cutting, China fiber laser pipe cutting machine can also perform oblique cutting, drilling, engraving, rotary drilling, etc., to achieve Diversified processing of pipes.

The laser cutting machine for metal pipe has become an indispensable tool in door and window cutting. With the development of laser technology, Internet of Things technology, and Internet technology, fiber pipe laser cutter has become more and more intelligent. of end customers experience tangible benefits.

Advantages of fiber pipe laser cutter:

1. Narrow slit and small deformation of workpiece

The laser beam of The fiber pipe laser cutter is focused into a very small spot, so that a high power density is achieved at the focal point. At this time, the heat input by the beam far exceeds the part that is reflected, conducted or diffused by the material, and the material is quickly heated to the level of vaporization, which evaporates to form holes. As the beam moves linearly relative to the material, the holes are continuously formed into narrow slits. The cutting edge is less affected by heat, and there is basically no workpiece deformation.

2. Non-contact processing

The laser beam of The metal pipe fiber laser cutting machine is focused to form an action point with extremely strong energy, which has many characteristics in cutting. First, the laser energy is converted into amazing heat energy and kept in a very small area, which can provide a narrow straight edge kerf; second, the laser beam does not exert any force on the workpiece, it is a non-contact cutting tool, which means that the workpiece has no Mechanical deformation; no tool wear, no need to talk about the problem of tool conversion; cutting material does not need to consider its hardness, and the cutting ability of the best fiber laser pipe cutting machine is not affected by the hardness of the material to be cut, any hardness material can be cut. Thirdly, the laser beam of the china fiber laser pipe cutting machine has strong controllability, high adaptability and flexibility, so it is very convenient to combine with automatic equipment, and it is easier to realize the automation of the cutting process.

3. Adaptability and flexibility

Compared with other conventional processing methods, the best fiber laser pipe cutting machine has greater adaptability. Compared with other thermal cutting methods, which are also thermal cutting processes, other methods cannot act on an extremely small area like a laser beam, resulting in a wide kerf, a large heat-affected zone and significant workpiece deformation. Lasers can cut non-metals while other thermal cutting methods cannot.

4. High cutting precision and high efficiency

The real difference of China fiber laser pipe cutting machine is the cutting precision. It adopts chuck and push cutting method, which has high centering precision and processing precision; Industrial manufacturing applications have been greatly accelerated. The laser cutting machine for metal pipe can be adjusted accordingly according to these deformations to ensure the precision of pipe cutting, which cannot be achieved by many traditional processes.

5. Support multi-angle cutting

China fiber laser pipe cutting machine adopts pipe cutting software, which can seamlessly identify pipe graphics drawn by 3D software, and supports automatic generation of some common pipe workpieces. The fiber pipe laser cutter can cut any programmed shape on metal pipe, and the laser can cut perfectly in any direction. Through computer programming design, it can be changed flexibly and quickly. best fiber laser pipe cutting machine

Its high flexibility provides a strong technical support for more and more personalized processing, thereby reducing the number of molds used.

BuyCNC has a variety of laser cutting machines, we also have a variety of power laser pipe cutting machines, and these laser pipe cutting machines are installed with accessories from internationally renowned brands, with high quality and long service life, laser pipe cutting machines The machine is widely used in the cutting of various types of pipes such as round pipes, oval pipes, square pipes, rectangular pipes and special-shaped pipes. Applicable pipe material types: carbon steel, stainless steel, alloy steel, aluminum, copper and other materials; it is widely used in doors and windows industry, fitness equipment, oil pipelines, engineering machinery, automobile manufacturing, household appliances manufacturing and other pipe processing industry.