Table of Contents

Many customers who have just started to learn CNC Stone engraving machine are not very familiar with all aspects of Stone Engraving Machine performance. They listen to the introduction of the salesperson, and then order blindly when they think it is very good. In fact, customers don’t know much about Granite Stone Engraving Machine, and they don’t know what kind of CNC Stone engraving machine they need is more suitable for them. So in this article, let’s talk about what to pay attention to when buying Stone Engraving Machine.

1. The Power of CNC Stone engraving machine

The CNC Stone engraving machine with low power is only suitable for the processing of two-color plates, architectural models, small signs, three-dimensional handicrafts and other products. This process has been popular for a while, but because the engraving power is too small, it greatly affects the application range of the machine.

CNC Stone engraving machine with a high-power spindle, this kind of CNC Stone engraving machine is divided into two categories, one is large-format Stone Engraving Machine, the format is generally more than one meter, but the accuracy of this CNC Stone engraving machine is generally poor; the other is Granite Stone Engraving Machine with a moderate format, This

Granite Stone Engraving Machine is generally used in fine finishing and organic signage.

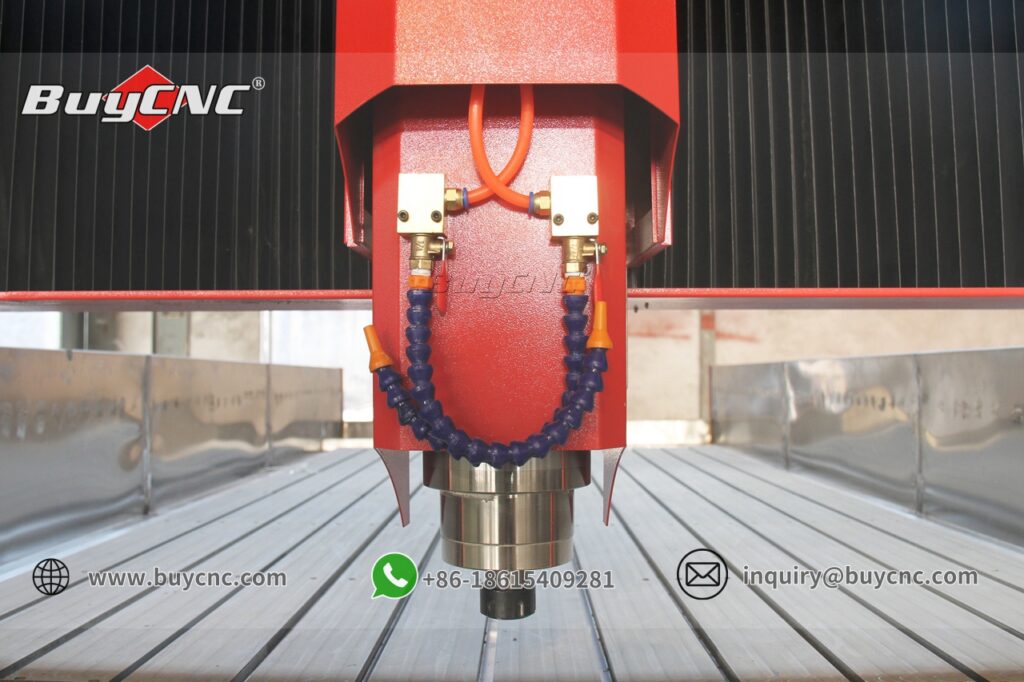

3.Granite Stone Engraving Machine spindle power

Granite Stone Engraving Machine generally 4500w, 5500W is enough, the processing speed can be guaranteed, and it can save power.

4.Selection of CNC Stone engraving machine bed frame

The CNC Stone engraving machine bed structure can be divided into several grades according to the load, such as cast aluminum structure, welded structure, cast iron structure, thickened square tube welded structure, and the most commonly used is thickened square tube welded structure.

5. Stone Engraving Machine motor selection

When choosing Stone Engraving Machine, be sure to check the performance of the motor. Whether the motor is normal or not is also critical. A bad motor will also affect the use of Stone Engraving Machine.

6. Granite Stone Engraving Machine controller

Granite Stone Engraving Machine controllers are divided into two categories: one type of controller needs to be connected to a computer before it can be used, and the control software is installed on the computer, and the computer controls the machine, such as Nc-studio; the other type can be used offline, that is, it does not need to be connected to a computer , the controller itself is equipped with a microprocessor, such as a DSP controller.

The above six points hope to help you choose the right machine when buying CNC Stone engraving machine .

If you need more information, please contact BuyCNC today.

Whatsapp: +8618615409281