Table of Contents

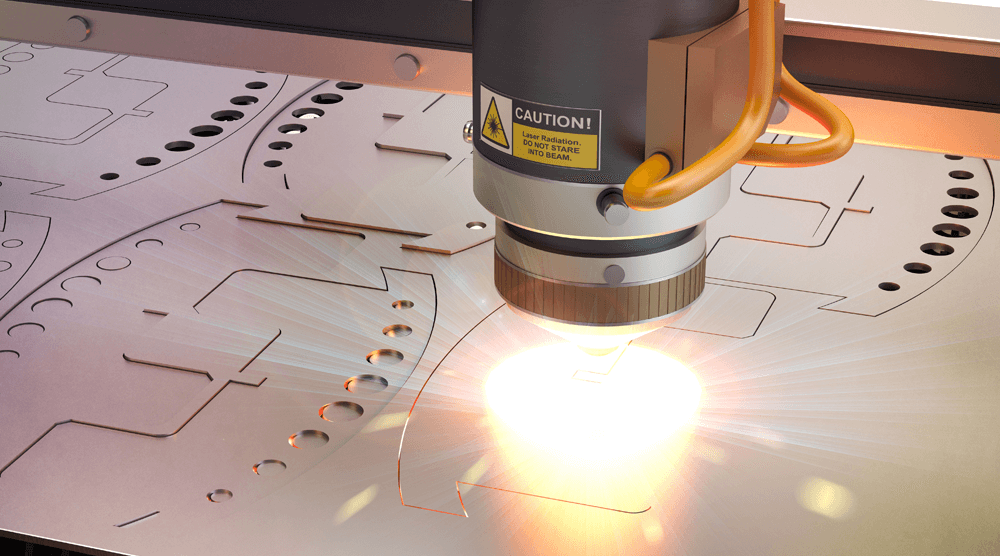

What is the Pulse And Continuous Fiber Laser

pulse

It is a mechanical form such as waves (radio waves/sudden waves, etc.) emitted at the same time interval.

laser pulse

It refers to a pulse of light emitted by a laser in the pulse operation mode. Simply put, it is like the work of a flashlight. Keeping the button on is continuous work, and when the switch is turned on, it is turned off immediately.

If it falls out, it sends out a “light pulse”. It is necessary to work with pulses, such as sending signals and reducing heat generation. Laser pulses can be made very short, such as “picoseconds”

level, that is, the duration of the pulse is in the order of picoseconds, and 1 picosecond is equal to one trillionth of a second (10E-12 seconds)

Continuous laser

The laser pump source continuously provides energy to generate laser output for a long time, thus obtaining a continuous laser. The output power of the continuous laser is generally low, which is suitable for the continuous operation of the laser.(such as laser communication, laser surgery, etc.)

The advantages of giant pulse laser and Continuous laser

giant pulse laser

The loss is artificially added in the cavity to make it greater than the gain of the working substance, and there is no laser beam at this time. However, under the continuous excitation of the pump source, the number of atoms in the upper energy level of the laser increases, and a large population inversion is obtained. If the peak power is defined as the energy of the pulse divided by the duration of the pulse (pulse width), then, in the case of removing the artificially added loss, a narrow pulse width, peak power can be generated at an extremely fast rate in a very short time. High pulsed lasers, often called giant pulsed lasers.

Continuous laser

CW laser, as its name implies, uses laser output continuously in time, pulsed laser output is discontinuous, and the shortest commercial energy can reach the order of several femtoseconds, so pulsed laser is often used for measurement Ultra-fast physical process. But the continuous laser also has advantages. After frequency stabilization, a very narrow line width can be obtained, which can be used for laser ranging and fine spectroscopy.

Continuous Fiber Laser VS Pulsed Fiber Laser

The peak power of pulsed laser cleaning and continuous laser cleaning is much different. The better semiconductor laser in the continuous laser can achieve the order of 100W, while the pulsed laser can now achieve the order of τw in femtoseconds, and the shorter the pulse width is. , hot work

The less the effect, the more pulsed lasers are used in fine processing.

Peak power = single pulse energy / pulse width;

Average power = single pulse energy * repetition rate

The pulse width of the laser is for pulsed lasers or quasi-continuous lasers, which can be simply understood as the action time of each emitted laser pulse or the duration of one laser pulse.

between. The repetition rate is the number of pulses emitted by the laser per second. For example, 10Hz means that 10 laser pulses are emitted in one second. However, the pulse width of each laser pulse is different for different lasers, whether it is nanosecond level, microsecond level or millisecond level.

| Continuous Fiber Laser VS Pulsed Fiber Laser | ||

| Contrasted | Pulsed Lasers | CW Lasers |

| Power | 100/200/300 | 1000/1500/2000 |

| Scanning width | 200mm | 1-16mm |

| Laser mode | Oil removal/paint removal/rust removal | None |

| Machine power consumption | 3000W | 6000W |

| Consumables | None | Protective Lenses |

| Laser linear | 4 Mode | single mode |

| Efficiency | No comparison item | High Rust removal Efficiency |

| Cooling method | Air cooling | Water cooling |

| Damage | No damage | Damage to the substrate |

| Machine Cost | expensive | Cheap |