What is Acrylic? How do I Cut acrylic material?

You may not know what PMMA is, but you must have heard these two words “acrylic” or “plexiglass”. Acrylic, a new type of transparent and colorful plastic material, not only has good weather resistance and easy processing, but also has smooth and wear-resistant surface. It has been widely used in construction, and has brought huge benefits to our life. For example, we are familiar with interior decorative chandeliers, transparent walls and car doors and windows are made of acrylic processing. Now, you must be interested in the classification of acrylic and how to cut acrylic to finish an acrylic exquisite decorations.

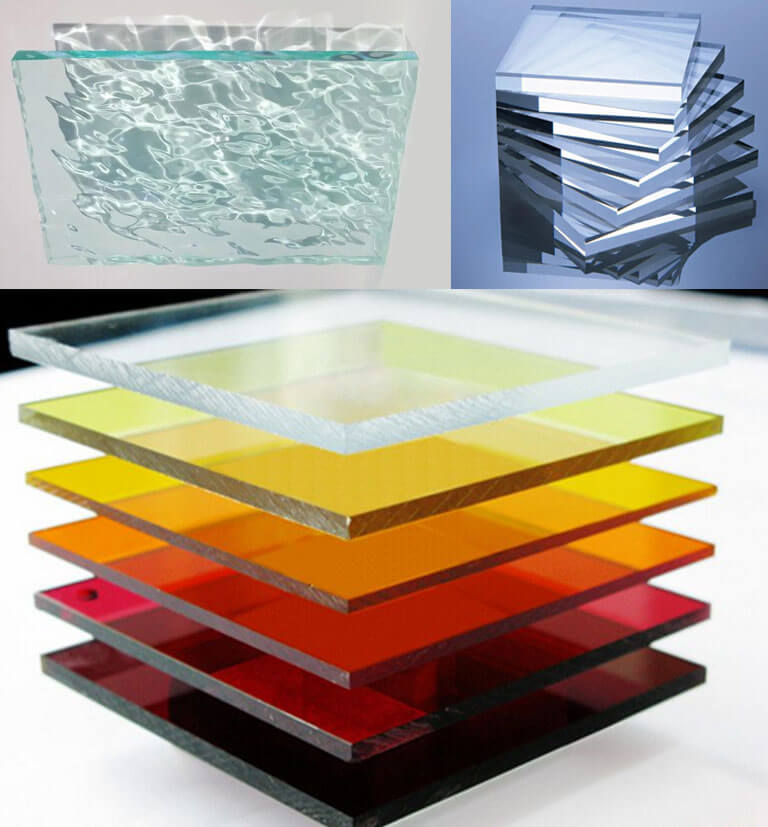

Due to the different production process, acrylic plate is divided into “casting plate” and “extrusion plate”. The casting acrylic plate has better elastic deformation resistance, rich colors and various surface textures; As the name implies, extrusion acrylic plate is made by high temperature extrusion of mechanical equipment, and compared with the extruded plate, the thickness error of the cast plate is smaller, which is easy to bend and heat forming. Usually, people divide acrylic sheets into “normal sheets” and “special sheets”. The common acrylic sheets include transparent sheets, milk whiteboards, and color sheets. And special acrylic sheets include bathroom sheets, metal effect sheets, etc.

What tools can cut acrylic? and how to finish acrylic?

Acrylic’s application fields cover many industries such as construction, industry, transportation, advertising, etc. In addition, the types and processing techniques of acrylic are diverse, so how to choose a suitable way to cut acrylic sheets is particularly important. The following is a detailed explanation on how to cut acrylic sheets better for acrylic DIY enthusiasts and professional acrylic finished products manufacturers.

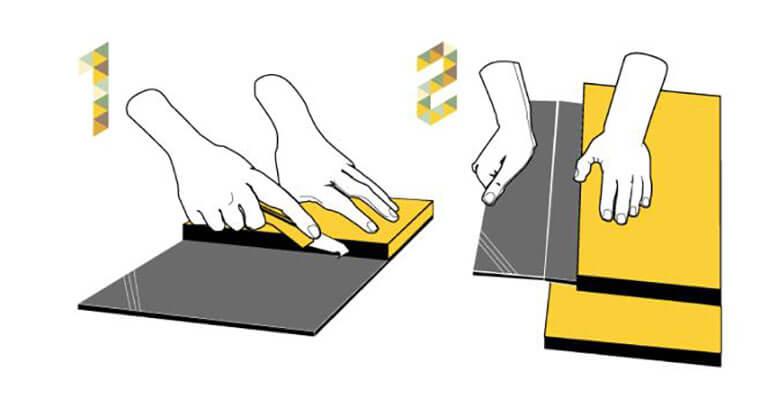

DIY Acrylic Small Hobby Business

For small DIY acrylic enthusiasts, the accuracy requirements for cutting acrylic are not so high. Therefore, you can prepare a hand saw and a fixed acrylic board for cutting. Of course, for thicker acrylic, a chainsaw is a good choice. You can refer to the picture below to cut acrylic.

Acrylic Finished Product Manufacturer

1. Vibrating Knife Cutting Machine

The principle of the vibrating knife cutting machine is to use a blade to cut acrylic materials. The choice of milling cutter, vibrating knife, and starting knife is based on the thickness of the acrylic. Among them, the milling cutter has the best cutting effect for acrylic cutting. And the cutting edge is exquisite. In addition, to ensure the accuracy of the vibrating knife cutting machine to cut acrylic, the staff must consider the height of the workbench, the type of blade and the sharpness of the blade. Real-time blade replacement to prevent excessive wear is also necessary.

2. Milling Cutter

Acrylic cutting and milling cutters are divided into double-edged ball-end milling cutters, special acrylic milling cutters, single-edged helical milling cutters, double-edged helical milling cutters, three-edged helical milling cutters, and end milling cutters. Down milling is beneficial to the defense of the blade shield. It should be noted that when the acrylic surface is left with an oxide film or other hardened layer composed of casting and forging processes, up-cut milling will be better.

3. Laser Cutting Machine

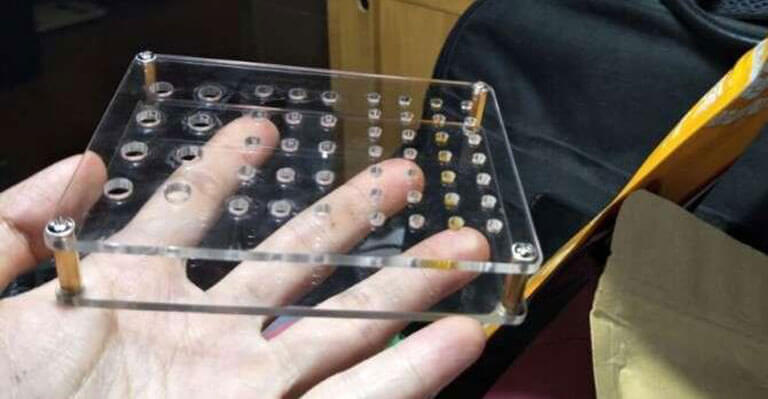

Many customers I have received, they asked me if the CNC machine can cut acrylic and how to engrave acrylic with CNC? My reply is yes! The CNC laser engraving machine can cut a variety of acrylic patterns and fonts. And it can also avoid the contact between people and the board. The cutting principle is to use the energy released by the laser beam to melt the surface of the acrylic material. The control system of the CNC laser cutting machine ensures the cutter can accurately cut acrylic with complex shapes. If the customer’s requirements are not very high, it can be delivered after cutting, and there is no need for flame polishing. On the contrary, only polishing is required.

Laser Cutting Machine-The Best Choice for Cutting Acrylic.

The CO2 laser cutting machine produced by BuyCNC has a wide range of uses. And can achieve precise cutting for acrylic, glass, leather, medium density fiberboard, metal, and paper. This CO2 laser cutting machine is equipped with two CO2 laser tubes, one of which can be used to cut thin metal plates and non-metallic plates with a power of up to 280w. And the other is 60w, which can cut acrylic. It can be said that it is a good machine for cut acrylic. How do you cut acrylic? And if you want to know more about how to cut acrylic with a router, welcome to consult us for free.