The CNC Router Bit Guide

What is The CNC Router Bits

CNC router bit is the most critical tool for CNC router machine to realize cutting, engraving, punching and other processes. The CNC router bit determines the type of processing you can complete and the quality of the final design. If there is no CNC router bit, then your CNC router machine cannot work.

The CNC router bit is divided into many types, and different cutting processes require different tools. If your project involves not only cutting, but also 2D and 3D engraving, punching, etc., do you know which CNC router bits you should choose? What should be considered when buying and using this type of CNC router bit? Next BuyCNC will provide you with a complete introduction about CNC router bit, such as what is CNC router bit. The CNC router bit is a cutting tool installed on CNC router machine for engraving and cutting work pieces. These cutting tools are collectively called CNC router bit,CNC router cutters, router machine bits, CNC engraving bits etc. CNC router bits of different types can achieve different processes.

The most widely used CNC router bits in the market:

1. Flat-bottomed engraving CNC router bit, also called column knives, mainly rely on the side edge for carving, and the bottom edge is mainly used for flat polishing. The end face of the head of the column bits is large, and the engraving efficiency is high. It is mainly used for contour cutting, milling plane, area rough carving, rough surface carving, etc.

2. Ball-end engraving CNC router bits, the cutting edge of the ball knife is arc-shaped, forming a hemisphere during the engraving process of the woodworking engraving machine, the engraving process is evenly stressed and the cutting is stable. So it is especially suitable for curved surface carving, often used for curved surface semi-precision carving and curved surface fine carving. Ball cutters are not suitable for milling planes.

3. Bull-nose engraving CNC router bit. Bull-nose router bits is a mixture of column knife and ball knife. On the one hand, it has the characteristics of a ball knife to carve curved surfaces, and on the other hand, it has the characteristics of a column knife and can be used for plane milling.

4. Taper flat-bottomed engraving CNC router bit, referred to as taper router bits. Cone knives have the widest application range in the entire engraving industry. The bottom edge of the cone bit, commonly known as the tip, is similar to a column router bits, and can be used for small plane finishing. The side edge of the cone router bit is inclined at a certain angle to form an inclined side surface during the engraving process. The structural characteristics of the cone knife can enable it to achieve the unique three-dimensional angle clearing effect of the carving industry. Cone knives are mainly used for single-line carving, regional rough carving, regional fine carving, three-dimensional clear corners, projection carving, image gray scale carving, etc.

5. Taper ball-end CNC router bits, referred to as taper ball router bits. The cone ball router bits is a mixture of cone bit and ball bit. On the one hand, it has the characteristics of a cone knife with a small tip, and on the other hand, it has the characteristics of a ball knife, which can engrave relatively fine curved surfaces. Cone ball knives are often used for relief surface carving, projection carving, image relief carving, etc.

6. Taper bull nose CNC router bits, taper bull nose CNC router bits is a mixture of cone bit and bull nose bit. On the one hand, it has the characteristics of a cone knife, which can have a smaller tip, engraving and milling relatively fine curved surfaces, and on the other hand, it has a bull nose knife. Because of its characteristics, the taper bull-nose knife is often used for relief surface carving.

7. The big head engraving CNC router bit is essentially a cone router bit with a larger head cone angle. Mainly used for three-dimensional angle clearing.

8. Drilling tool, mainly used for drilling. When the hole is shallow, you can use a flat-bottomed knife to drill.

The above are some of our most common Engraving CNC router bits. So do you know what materials these CNC routers bits are suitable for processing and what features they have?

The Features and applicable materials of the CNC router bits

1.Single flute spiral router bit (carbide)

Main function: two-dimensional cutting

Applicable materials: acrylic, PVC, medium density board

Features: Combining the advantages of single groove design with strong cutting force and smooth chip removal, and spiral cutting to ensure the smoothness of the cutting surface, it has a good working efficiency in batch processing of PVC and MDF.

2.Double-edged spiral router bit (hard alloy)

Main performance: two-dimensional cutting, two-dimensional carving

Applicable material: natural wood, synthetic wood can also be used for plastic

Features: Special wood processing tools. This type of double J tool is used to process wood and synthetic wood. It is easy to remove debris, the blade is strong, durable, and the processing effect is good (to ensure that the surface is free of burrs).

3.Single-edged straight groove CNC router bits(carbide)

Main performance: two-dimensional cutting

Applicable material: cork, medium density and medium hardness wood, also can be used for: elastic, anti-friction plastic

Features: Combines slotting design and single-edge geometric design, which is convenient for automatic chip removal during fast cutting

4.ball end engraving CNC router bits (hard alloy)

Main performance: three-dimensional engraving, two-dimensional cutting

Applicable material: organic (acrylic) can also be used: black metal.

Features: The choice of the blade width of the ball milling cutter mainly depends on the accuracy and size of the surface carving. It is generally divided into two engravings. For rough carving, you can choose a larger tool diameter, and for fine carving, you should choose a tool with a smaller blade diameter.

5.double-edged straight groove engraving CNC router bits (hard alloy)

Main performance: two-dimensional plane carving, two-dimensional cutting.

Applicable materials: medium density fiberboard, hardwood, acrylic

Features: Designed for CNC engraving MDF material, combined with special hard alloy, hard blade body and advanced blade geometry, durable. It also has a high work efficiency in the rough machining of non-ferrous metals.

6.Surface cleaning CNC router bits(carbide)

Main performance: clean the surface of the product

Applicable materials: organic (acrylic), PVC, medium density board

Features: When any engraving machine is working, it is necessary to ensure that the engraving plane is flat, especially when performing 2D and 3D engraving. In order to save trouble, some sculptors tend to be sloppy. The products they engrave are either substandard or require manual modification.

7.Single edge column router bits (carbide)

Main performance: two-dimensional cutting

Applicable material: two-color board, plastic board, also can be used: acrylic board with thickness below 3mm.

Features: For cutting two-color boards, if there is no special requirement, you can usually cut the finished product when you pick it up, but the sharp knife is easy to dull after cutting, and there will be burrs after engraving. The design principle of a single-edged column knife is similar to that of a sharp knife, but it is Vertical cutting, no slope, especially suitable for the design of inlay process.

8.Double-edged spiral router bit(carbide)

Main functions: two-dimensional cutting, two-dimensional plane carving.

Applicable material: organic (acrylic), PVC, also can be used for: black metal.

Features: It has good red resistance and abrasion resistance for dry cutting of organic plates, and the spiral blade cutting ensures the smoothness of the surface of the object. It has excellent performance when cutting thicker plates. It can also be used to process ferrous metals, such as iron and steel.

9.3D Carving router bits (Carbide)

Main functions: three-dimensional corner clearing, chamfering

Applicable material: organic, PVC. Can also be used for: MDF, medium hardness wood

Matters needing attention: Whether it is engraving or reverse engraving, be sure to keep the engraving plane flat; it is very important to choose a suitable blade width for three-dimensional clear-angle engraving. It is recommended that the blade width of small-format engraving machine should not exceed 22mm, and that of large-format engraving machine A tool with appropriate blade width can speed up the engraving speed.

The quality of the engraved workpiece of the CNC engraving machine is not only determined by the performance of the engraving machine itself, but also affected by many external factors. For example, the experience of operator and can you choose the right CNC router bits according to the material?.Now Let’s learn how to choose the suitable engraving CNC router bits type and spiral router bit.

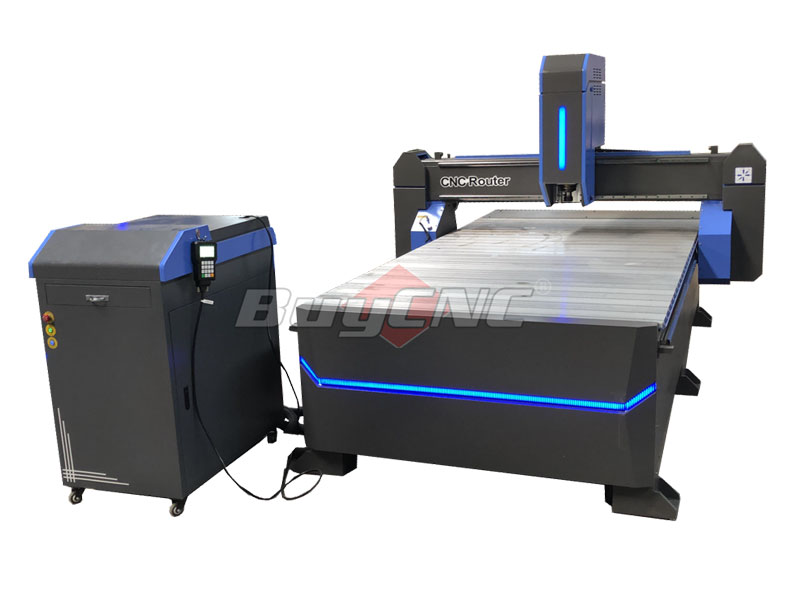

As a professional woodworking CNC router with vacuum table machine, this machine body is welded by thick steel pipes, so it is enough strong to process different materials. And it has many advanced kit such as Hiwin linear rails and bearings, Germany precision helical racks on the X and Y axes etc. It is worth mentioning that the powerful CNC vacuum pump of the CNC router for sale machine can vacuum the material within 3 seconds. This greatly improves the work efficiency of woodworking CNC router machine.

How to choose the suitable CNC router bits

1.Choose a CNC router bit with a proper length: The choice of tool blade length should be to add 2-3MM to the thickness of the processed plate as the most suitable blade length. The speed of the cutting acrylic motor is 18000-24000 rpm, and the cutter blade is too long to be used for processing harder materials.

2.Choose the appropriate CNC router bits according to the target: small angle and small knife-point tools should be used when engraving fine text patterns. When engraving large text patterns, try to choose large angles and large knife points without affecting the accuracy requirements . The carving knife processing path design At the same time, try to maximize the angle and tip of the tool to improve the efficiency of engraving. The engraving material should have a large angle with a harder material, and the tip of the knife should be large.

3.Woodworking engraving machine CNC router bits frequently appears broken knife situation, the appearance of this kind of thing is not only related to the quality of the knife. It is also related to your engraving setting habits, the precision of the engraving machine guide motor , the plate, and the fixture, so we have to choose CNC router bits type according to the processing method.

4.For woodworking engraving CNC router bits, the staff must understand that low-power spindle motors (with smaller fixtures) should choose small-handle tools (3.175 mm, 4.0 mm) and the cutting speed should not be too fast. In high- speed milling To keep the minimum resistance and obtain the best cutting effect, the high-power motor can use large shank tools to increase the engraving speed.

Matters needing attention when using CNC router bits

1. The size of the router bits jacket should be appropriate. The jacket has a cross-section, the inner hole is not round enough, the jacket that is worn for a long time, and the inner hole has a taper must not be selected , which will easily cause the tool handle to tremble and the engraving will not be satisfactory.

2. The tool holder must match the jacket and be able to enter and exit the jacket smoothly. The tool holder must be firmly put into the jacket and tightened. If the tool jacket is used for a long time, the inner hole is deformed, and a new one should be replaced. set.

3. Always check the toughness and sharpness of the Router bits. If you find that the tool is blunt or the knife edge is damaged, it is best to replace it immediately. If you continue to use it, not only the engraving effect is not good, but also the danger of breaking the router bits.

4. The thickness of the processed material cannot exceed the thickness of the cutting edge that can be cut and engraved, otherwise the spiral router bit will be broken or the engraving effect will not be ideal.

5. For engraving and cutting of different materials, different spiral router bit should be selected and the cutting and engraving speed should be modified reasonably.

6. During the working process of the engraving machine, the high-speed rotating knives are very sharp. Please pay attention to keep your body parts away from the objects being processed, and especially pay attention not to wear too wide overalls. Women should bandage their hair to prevent accidents..

7. The engraving and cutting speed should be balanced, and the processing speed should be as consistent as possible. The engraving and cutting process should be done in one go to prevent the occurrence of broken points and cut marks.

8. It is best to use professional cleaners to clean router bits.

9. When the spiral CNC router bits are not in use, applying butter can prevent the knives from rusting.

10. Don’t polish and change the shape of the blade by yourself.

BuyCNC has a variety of router bits CNC machine for sale,If you want to know other engraving CNC router bits,such as the spiral upcut router bit,spiral router bit,router bits for acm panels,router bits for aluminum,etc.Please leave your contact informations.