Table of Contents

What is The CNC Coolant System

Coolant, also known as cutting fluid, is a kind of lubricant. The Coolant system can help CNC machine tools to easily cut materials such as metal, glass fiber and high-density plastics.When we process products at a lower cutting speed, the coolant helps to lubricate the cutting process; when we process products at a high cutting speed, the coolant can cool the workpiece and prevent particles and debris from flying away.

Coolant is one of the most important components in the processing process and plays a vital role in extending the life of the machine. Problems with the coolant system can lead to processing bottlenecks, poor product quality and long downtime.

The Types Of Coolant

The coolant is divided into three categories-synthetic oil, soluble oil and straight oil.

1.Synthetic oil

The synthetic fluid contains organic and inorganic alkaline components instead of petroleum or mineral oil. These types of cutting fluids are relatively cheap, can protect the processed workpiece from corrosion, and have excellent cooling performance.

2. Soluble oil

These solubles are basically made of a mixture of emulsion and mineral oil base material. Because they have good solubility with water, we can mix it with water to achieve a cooling effect. Now it is the most widely used coolant.

3. Straight oil

The last type of coolant is Straight Oils, which is composed of a mineral oil base or use. But it also includes other lubricants, such as vegetable fats. Although straight oil is a good lubricant, it can hardly cool the machine effectively, so straight oil is less used.

Type of Processing CNC Coolant System

After we have selected the appropriate coolant, we need to apply the coolant to the machine or workpiece through the coolant system. The CNC coolant system is a machine connected to the CNC router machine. It is mainly used to transport coolant through a pump to lubricate and cool the workpiece and the CNC router.

Some common coolant systems include:

Overflow system: This system pours a large amount of coolant on the surface of the workpiece and the machine. Overflow helps chip management during processing, but this system wastes more coolant.

Jet system: Jet coolant system releases cutting fluid at high pressure. The fluid is directed to the cutting edge to achieve better lubrication and cooling. This system can effectively achieve cooling and lubrication functions.

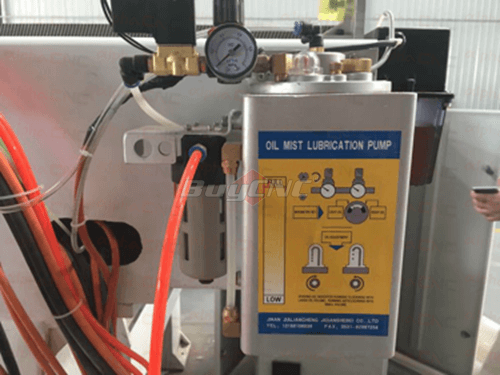

Oil Mist system: The spray coolant system releases fluid that is atomized into small particles. In this way, the coolant looks like mist or mist when sprayed onto the workpiece. The atomization system can provide the best lubrication effect, especially in high-speed applications. Now the CNC oil mist coolant system is the most popular coolant system.

What Can The CNC Coolant System Do

Nowadays, more and more machines are equipped with advanced cooling systems in order to improve the cutting quality of CNC router machines. All the machines sold by BuyCNC can be equipped with oil mist cooling systems. This CNC Coolant system can remove debris generated during processing, Lubricate metal processing, cool down. Next we analyze these three functions in detail.

1.Clear The Scrap:

When you are processing materials, the CNC coolant system can spray coolant at the incision, which can keep the chips generated by the machining away from the cutter, which means that the cutter needs to remove fewer chips and the old chips will not be tilted Or hit the cutting wall. But if you don’t use the CNC coolant system, this will destroy the finish of the material, and even some cutters will break due to being blocked by debris, so this CNC coolant system is necessary.

2. Lubrication function:

The second main function of the CNC coolant system is the lubrication function. When you process metals such as aluminum, copper, etc., because these materials themselves have a certain viscosity, they will try to bond themselves to the tool, but this CNC coolant system can lubricate the metal and the tool, thereby avoiding metal chips and the tool Bonding.

3. Cooling function:

Compared with air cooling, the liquid and oil mist cooling system can take away better heat and has an excellent cooling effect.

Other functions of coolant in processing include:

1. Protect the machine from corrosion

2. Cool hot surfaces to ensure safe handling of machines and workpieces

3. Extend machine life

4. Protect the workpiece from deformation due to high temperature

5. In some applications, using the right type of cutting fluid can also help achieve high-quality finishes to meet customer needs.

Jinan BuyCNC can choose to install advanced oil mist cooling system for the products developed by Jinan BuyCNC. The system is low in price, has strong cooling and lubrication ability, can improve the quality of metal cutting and prolong the service life of the tool. If you want to know more information, you can Contact us directly and we will try our best to help you solve the problem.