Table of Contents

Welding method of laser welding machine

Laser welding machine is a new type of welding method, mainly for the welding of thin-walled materials and precision parts, which can realize spot welding, butt welding, stitch welding, sealing welding, etc. Small size, small deformation, fast welding speed, smooth and beautiful welding seam, no need or simple treatment after welding, high welding seam quality, no pores, precise control, small focusing spot, high positioning accuracy, and easy to realize automation. The main welding methods of laser welding machine are:

1. Pulse laser welding: The pulse laser welding method of the laser welding machine is mainly used for the welding of single-point fixed continuous and thin materials, and a circular welding spot is formed during welding.

2. Plasma arc welding: The welding method of this laser welding machine is similar to that of argon arc, but its torch will generate a compressed arc to increase the arc temperature and energy density. for laser welding.

3. Continuous laser welding: This welding method is mainly used for welding and cutting large and thick parts, and a continuous weld is formed during the welding process. Generally speaking, the choice of welding materials, the choice of laser welding machine brand, and the choice of processing table are the main factors that affect the effect of laser welding.

4. Electron beam welding: It relies on a beam of accelerated high-energy density electrons to hit the workpiece, generating huge heat in a small dense area on the surface of the workpiece, forming a pinhole effect, thereby implementing deep penetration welding. The main disadvantage of electron beam welding is that it requires a high vacuum environment to prevent electron scattering, the equipment is complicated, the size and shape of the weldment are limited by the vacuum chamber, and the quality of the assembly of the old weldment is strict, and non-vacuum electron beam welding can also be implemented, but due to the electronic Scattering and focusing do not affect the results.

Comparison of laser welding machine and other welding methods

(1) Brazing: The characteristic of conventional brazing is that the base material to be welded does not melt, and another low-melting alloy is used as the brazing material to connect the two base materials. Laser welding can save lining and reduce material consumption, and at the same time increase the working temperature of welded joints and improve joint performance.

(2) Arc welding: Many different types of arc welding transfer heat to the surface of the joint, resulting in wide seams and molten stacks. When deep penetration welding is performed, it is necessary to use filler wire for multilayer welding. It is the opposite of energy-concentrated laser welding, where the total heat input to the workpiece is high in arc welding, resulting in deformation and human heat-affected zones

(3) MIG welding: It uses consumable electrodes and shielding gas, which can be automated and used to weld most metals. Laser welding does not require electrodes, has small deformation, high speed, and can be single-pass double-sided welding and secondary forming. However, MIG welding is more suitable for thick workpiece connection than laser welding. Of course, filler wire should be added at this time.

(4) TIG welding: Non-consumable electrodes and shielding gas are used to weld thin workpieces, but the welding speed is quite slow, and the heat input is much higher than that of laser welders, which is prone to deformation.

(5) Submerged arc welding: Laser welding does not require flux and welding wire used in submerged arc welding, and the deformation is also small and the speed is steep.

(6) Plasma arc welding: it is similar to tungsten argon arc welding, but its torch produces a compressed arc: to increase the arc temperature and energy density. It is faster and deeper than tungsten argon arc, but it is still inferior to laser welding.

Application industry of laser welding machine

In order to meet the needs of different industries, there are many types of laser welding machines. According to different working modes, it can be divided into handheld laser welding machine, laser spot welding machine, fiber transmission laser welding machine, automatic continuous fiber laser welding machine, multi-axis laser welding machine and galvanometer laser welding machine.

The industries and materials of laser welding equipment are as follows:

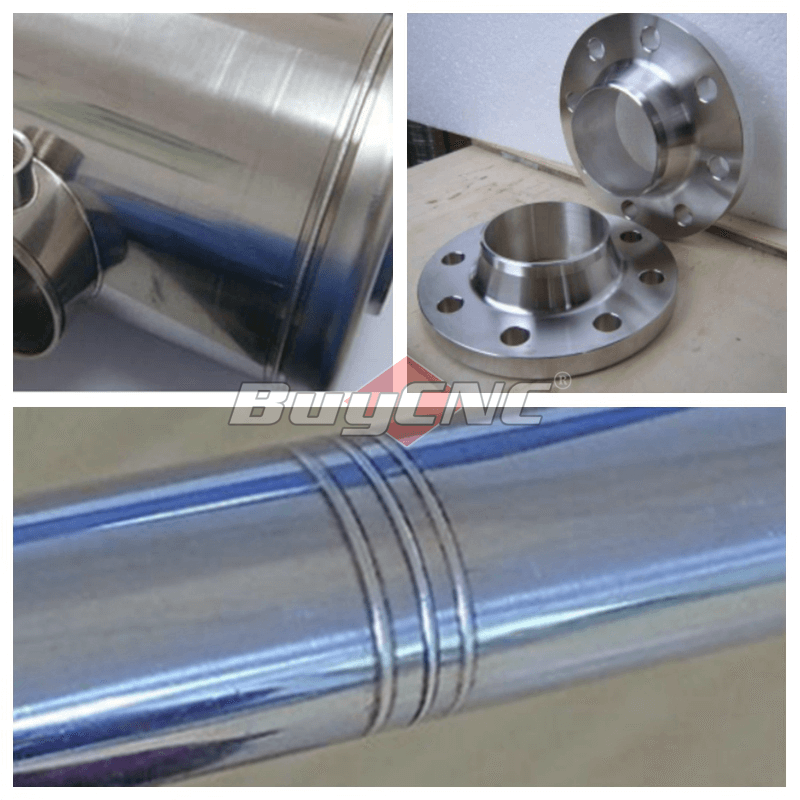

Sanitary ware industry: Welding of water pipe joints, tees, valves, showers.

Glasses industry: stainless steel, titanium alloy and other materials gusset plate, precision welding frame and other positions.

Hardware industry: Welding of complex stamping parts and castings such as impellers, kettles, handles, etc.

Automotive industry: engine cylinder head gasket sealing welding, hydraulic tappet, spark plug welding, filter welding, etc.

Medical industry: welding, stainless steel seals, medical equipment, medical equipment and structural parts.

Electronics industry: solid state relay sealing welding, connector welding, MP3 and other metal shells and structural parts. Welding of motor shells, wires, fiber optic connectors, etc.

Household hardware: kitchen utensils, stainless steel door handles, electronic components, sensors, clocks, precision machinery, communications, handicrafts and other industries, automotive hydraulic tappets and other high-strength products, welding products.

It is precisely because of the strong welding ability and fast welding speed of the laser welding machine that it can be widely used in a variety of materials and industries, so our laser welding machine has become more and more popular, BuyCNC provides a variety of laser welding machines, If you want to buy a laser welding machine, we will recommend the most suitable and affordable machine for you.

Laser Welding Machine For Sale