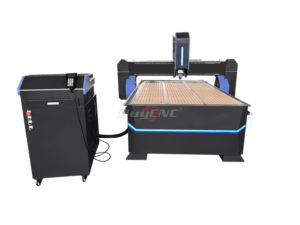

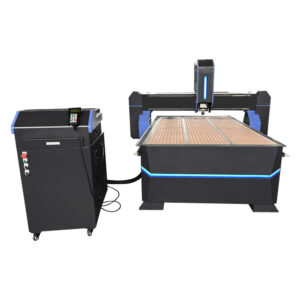

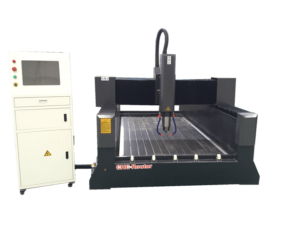

Granite Stone Polishing Machine for Sale

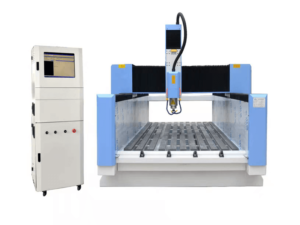

On the basis of the advanced stone technology and the advantages and disadvantages of the countertop CNC machine on the market, Buycnc developed this stone cutting and polishing equipment that integrates cutting, grinding, drilling and polishing. Of course, we also refer to a large number of customers’ own requirements for marble cutting and polishing process technology. The granite stone engraving machine adopts a powerful 5.5KW spindle, which is very suitable for cutting and polishing quartz countertops and other desktop cutting edges. The processing technology is high-end and the granite polish machine price is adorable. It is worth mentioning that the CNC sink cut out machine is a perfect marble cutting product.

Stone Cutting and Polishing Equipment Video

Feature of Granite and Marble Polishing Machine

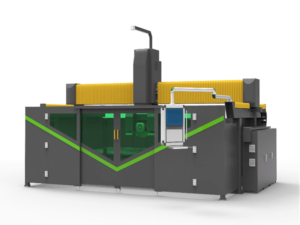

ATC system realizes highly automated processing of CNC granite

The straight-line automatic tool change system makes each processing of the marble granite polishing machine complete in one time. This includes from the initial opening, cutting, to milling edge forming, and then to the final polishing. The granite polishing equipment saves a lot of time and labor costs for manual tool change. In addition, we are equipped with tools of various specifications and shapes to meet your processing needs. The countertop CNC machine fully realizes the line-type table processing.

CNC tools easily achieve precise positioning of granite router machine

The CNC Tool Calibration of the granite sink cutting machine can easily and accurately find the origin of the work piece, and it allows the program to accurately use the "Z" zero position for one or more tool changes. In addition, the stone cutting and polishing equipment's tool sensor can automatically measure the distance from the tool tip to the work piece. When you use an air-cooled HSD spindle, the automatic tool changer needs to use tool instruments instead of tool sensors. Greatly improve the accuracy of the CNC sink cut out machine processing.

Strong stability, high precision, long granite stone cutter machine life

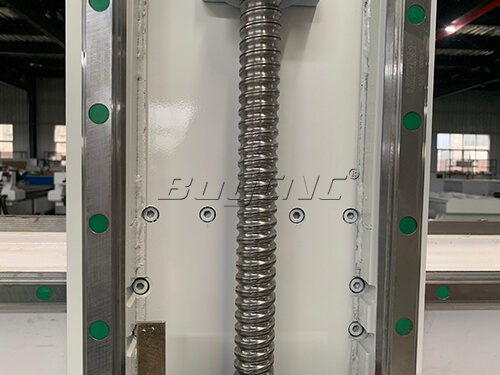

The auto polish machine for granite has a strong hardness, which depends on the countertop CNC machine using wider and thicker beams. And stone cutting and polishing equipment is not easy to deform when processing hard stone and it has high stability. The granite sink cutting machine adopts Taiwan Hiwin square rail and it is durable. The use of TBI ball screws makes the CNC gemstone cutting machine very precise. In addition, the special waterproof and antifouling structure designed by BuyCNC for the marble stone cutting machine can extend the service life of the guide rail while ensuring the processing accuracy.

Application for Stone Cutting and Polishing Equipment

| CNC sink cut out machine application industry | Stele processing Industry | |

| Advertising | ||

| Ceramics | ||

| Stone Industry | ||

| Artistic Relief | ||

| Decoration industry | ||

| Material that can be cut by granite sink cutting machine | Granite | Marble |

| Black stone | Jade | |

| Artificial stone | Glass | |

| Bamboo wood | Quartz stone | |

| Ceramic | PVC board | |

| Organic glass | Aluminum | |

| Plastic board | Others | |

Technical Parameters of Granite Carving Machine

| Descriptions | Stone Cutting Polishing ATC CNC Machine Parameters |

| Model | ASC-3015-ATC Custom Made |

| Working Size | 1500*3000mm/5x10ft Other size |

| Accuracy | ±0.03mm |

| CNC Router Table Surface | Heavy duty steel T-slot table |

| Frame | Thicken steel Square Heavy structure |

| X, Y Structure | Gear and rack Transmission |

| Z Structure | Taiwan TBI Ball Screw |

| XYZ Guide rail | Hiwin square rail 30mm |

| Spindle Power | Powerful 5.5KW Mechanical Servo Spindle |

| Spindle Speed | 0-8,000RPM |

| Fast feeding speed | XY: 20000mm/min, Z: 8mm/min |

| Drive Motors | Servo motor and driver |

| Way of fixing Workpiece | Vacuum cup sucking |

| Vacuum pump | 5.5kw |

| Tool magazine position | 10 posion in linear |

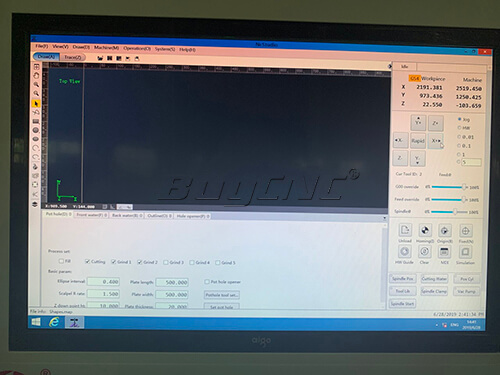

| Controller system | Nc-studio NC 65C |

| Working Voltage | AC380V/3PH/50Hz (option:220V or custom made) |

| Command Language | G Code |

| Software | Option: Vectric Aspire, Type3, Ucancam, Artcam, AlphaCam, Powermill, Solidworks,etc. |

| Running Environment | Temperature: 0℃~45℃ Relative Humidity: 30%~75% |

| Net/Gross Weight | 4000kg/4200kg |

Main Parts of Stone Cutting and Polishing Machine

Granite Stone Cutting Tool shank 8-12pcs (BT40)

There are 12 positions of tool shanks on the back of the countertop CNC machine. The position of the tool shanks will not affect the normal use of the granite sink cutting machine. And the position of the rack is convenient for loading and unloading materials from both sides of the granite cutting and polishing process machine. We are equipped with knives and abrasive tools of various specifications and shapes for you to choose.

CNC Router Countersink Machine's Heavy Bed

Our bed of stone cutting and polishing equipment can maintain good stability and accuracy during long-term use. And our bed is made of 8mm steel, and most of the merchants on the market now use 4.8mm steel. The life of the CNC sink cut out machine can be doubled, it is your best choice.

XY Helical Rack and Pinion of CNC Router Countersink Machine

The stone cutting and polishing equipment use precision helical gear racks on the X and Y axes. The rack is installed upside down to prevent dust and debris from accumulating in the drive system. The precision gearbox is directly coupled to the stepper motor and pinion. This eliminates the inaccuracy of belt tensioning and ensures high-speed processing when the system accurately positions the spindle of the countertop CNC machine.

Granite Processing Machinery Software- MACH 3

The MACH3 sandstone cutting equipment free software connected to the CNC vacuum table’s computer is used to control the vacuum program for granite engraving. MACH3 is developed by American programmers and is the most commonly used software for CNC machines worldwide. When you are not going to use the MACH3 system, don’t worry, our alternative systems are DSP, Nc-studio, etc. The Ethernet interface controller card has high reliability and anti-interference.

XY Z Axis Hiwin Square Rail of Sandstone Cutting Machine

Hiwin square rail of polishing cut granite has higher stability and stiffness, which allows the gantry and main shaft to move at high speed and high precision. The quality of Hiwin square rail is very good and more durable.

Z Axis TBI Ball Screw of Granite Sink Cutting Machine

Z axis is with TBI ball screw to ensure the stone cutting and polishing equipment with higher precision and longer service life.

Weihong Nc-studio Control Board

Tool Lock Holdere

Stone CNC Polishing Tools

Servo Motor

Nc-studio Handwheel

Granite Marble Quartz Stone Countertop

Granite Marble Quartz Stone Countertop

Control Switch

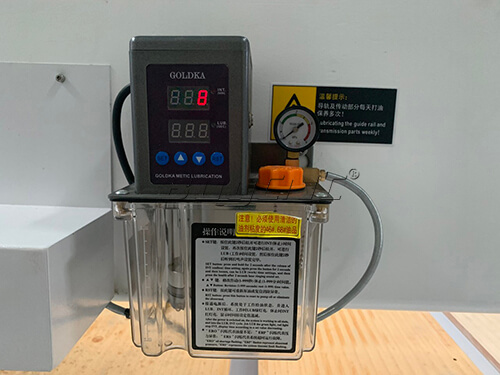

Automatic Lubrication Pump

Projects for Stone Cutting and Polishing Equipment

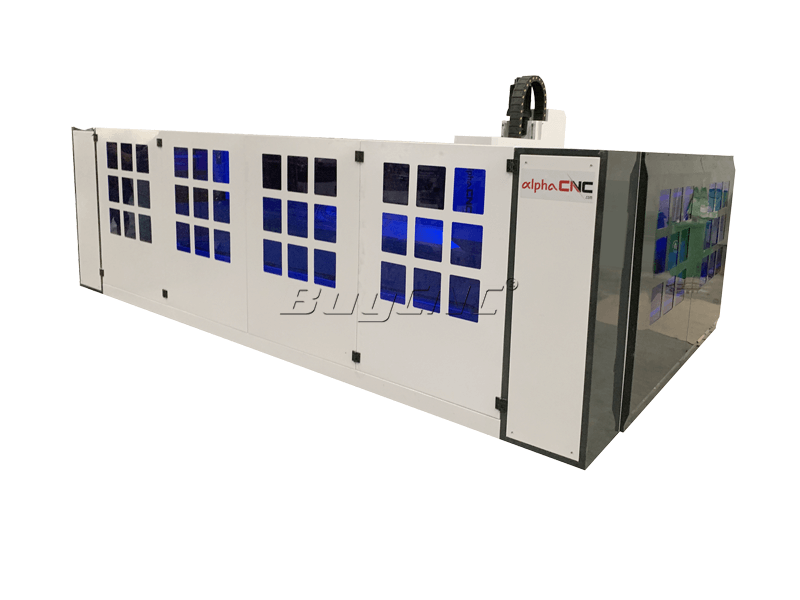

Strong Factory Strength of Granite Polishing Machine for Sale

BuyCNC is with advanced and powerful machining capability. We have high precision 5 axis CNC Machining center to process the machine frame. The top milling, side milling, and side drilling will be finished in the same machining center by one clamping, which ensure our granite sink cut out machine are with higher precision. Not only the machine frames but also the small machining parts are machined by ATC CNC Center too.

High Precision Installation of Granite sink cutting machine

During the installation of key components such as guide rails and racks, a dial indicator is used to check the installation accuracy to ensure the high precision of the machine.

Our Service of sink cut out machine

Packing for Stone Polishing Machine Suppliers

- 1: PVC film packing, which can ensure that the machine is completely covered, avoiding water and rust.

- 2: Wooden box packing, with a fixed template on the outermost layer.

- 3: All of the packing are inspected carefully by QC before delivery.

Pro-Sale Service of Granite Machinery Manufacturers

- Free sample testing service: you can send us the CAD file of the sample you want to cut, we will cut it at the factory and send the cutting video to you, or we can mail the sample to you.

- Personalized customized solutions: In order to meet your needs of cutting quality and efficiency, we can design unique solutions according to your requirements.

- Inquiries and consulting services.

After-Sale Service of Granite Polishing Machine Manufacturers

- The warranty period is 2 years for the granite sink cutting machine.

- When you need to replace the wearing parts, we will provide them at the agent price.

- If there are any problems during the warranty period, we will replace the main parts free of charge.

- The machine software provides free lifetime update service.

- 24-hour online technical support (phone, email, Teamviewer, Whatsapp, Skype, WeChat, QQ, etc.)

- We provide English training videos and user manuals for Machine installation and operation, etc. We can also provide technical guidance remotely.

- Free training at the BuyCNC factory.

- The engineer can repair the machine overseas.

Delivery of Nearby Stone Cutting Machine Manufacturers

All of the stone cutting and polishing equipment can be shipped worldwide. You can choose shipping by sea, by train, by truck, by air or by international express and DHL, FEDEX, UPS, etc. Click the button below to submit your information, we will provide you with professional service. Welcome!

Related Products

Related articles

Woodworking CNC Machine Operation is Simple and Intuitive

Table

About BuyCNC

BuyCNC is a leading High-quality CNC Machine supplier in China. BuyCNC develops and sells various CNC machines including CNC Routers, Laser Machines, and Plasma Cutting Machines. Our main products are wood CNC router, stone CNC router, metal CNC router, ATC CNC router, 4 Axis CNC router, 5 Axis CNC router, CO2 laser engraving cutting machine, fiber laser cutting machine, fiber laser marking machine, fiber laser welding machine, and metal plasma cutting machine etc.

The production complies with European standards and international quality control and has FDA, CE, SGS, and ISO9001 certification. The factory produces more than 1,000+ machines annually. And BuyCNC has Rich R & D’s experience which has been focusing on researching, developing, and manufacturing CNC machines for more than 20 years. Serving more than 150 countries and regions, we have 10000+ customers all over the world.

You can get the 4×8 CNC router wood directly without any CNC router distributor. Don’t hesitate anymore, tell us your needs to buy an cheap CNC router from BuyCNC.

Working Hours

Monday- Thursday:8:00-18:30 Hrs

Phone&Whatsapp&Wechat: +86 186 1540 9281

Website: www.buycnc.com

We Are Here

Dinghao Square, Xiaxia District, Jinan, Shandong Province, China

Reviews

There are no reviews yet.