The Factors About Vacuum Work Table

1. What types of CNC Router table tops are there?

CNC Router table is generally divided into Aluminum T-slot table and vacuum table.

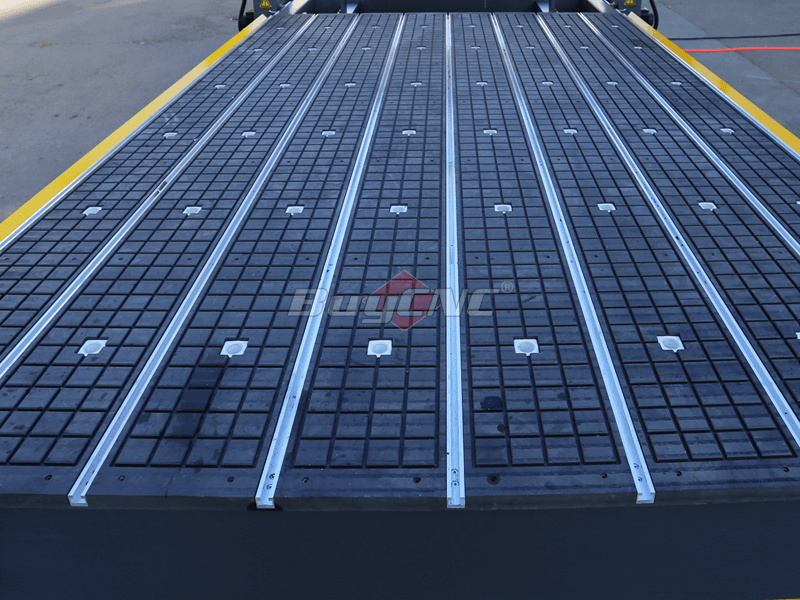

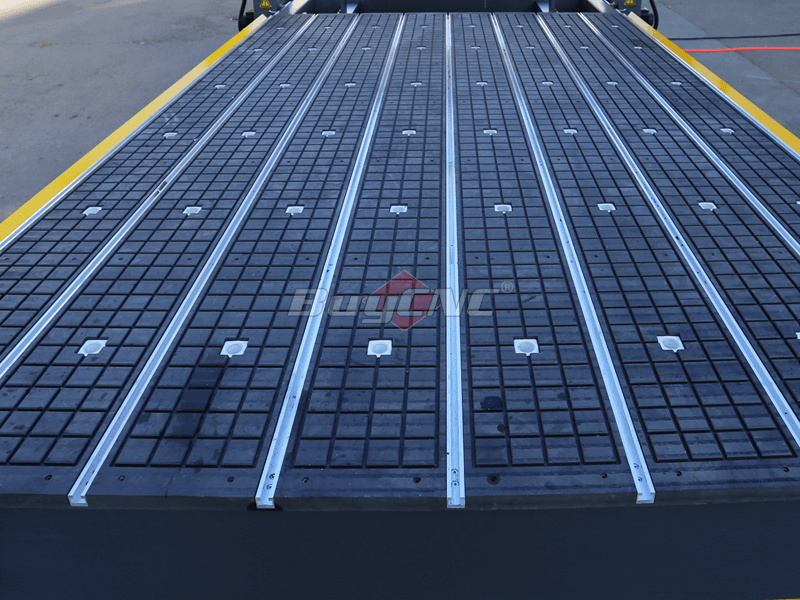

Aluminme T-slot Work Table:The Aluminum T-slot table is an aluminum profile with a T-slot at the bottom and a layer of PVC material on the top. As the name implies, it is to fix the workpiece material with a fixture, and then use the CNC Router to work. This can be arbitrarily fixed according to the size and thickness of the workpiece. Such a table saves costs, and the price is lower than that of a vacuum table. However, it takes longer for the Aluminum T-slot table to fix the workpiece. Workers need to screw the screws. The entire process of fixing the workpiece takes about a few minutes. Therefore, it is more labor intensive and low production efficiency. For workpieces with materials that cannot be absorbed, such as copper and aluminum, an engraving machine with an aluminum profile table must be used.

At present, in the field of engraving machine use, there are more customers of BuyCNC CNC engraving machine using vacuum adsorption table, which saves the time of fixing the plate and improves the processing efficiency. Therefore, when customers are purchasing equipment, they choose according to their processing requirements.

Vacuum Work Table: The material of the vacuum adsorption table is generally hard PVC or bakelite. Use a vacuum pump to connect to the bottom of the CNC Router table through a pipeline. There are multiple adsorption holes on the CNC Router table. When we put the wooden board on the CNC Router table, press the button, the wooden board is firmly absorbed on the CNC Router table by the negative pressure generated by the vacuum pump, and then the CNC Router starts to work. The entire upper material fixing process does not exceed ten seconds, with high efficiency and fast speed. The cutting requirements of the vacuum adsorption table are air-tight! Cutting hollow is not suitable. Special-shaped plates are also not suitable. Suitable processing materials: ordinary density boards with a thickness of about 2 cm are very suitable. Too thin is not suitable, it will be recessed when sucked. If it is too thick, it won’t work.

2.Which is better? Aluminum T-slot table or vacuum table?

Aluminum T-slot table and CNC Router vacuum table each have their own advantages, and we cannot simply say which one is better. From the perspective of the speed of fixing the workpiece, the CNC Router vacuum table is of course faster, which only takes more than ten seconds, which is more efficient than the aluminum T-slot table which takes a few minutes to fix the workpiece. However, some materials and processing techniques are not suitable for CNC Router Vacuum Table. Therefore, we should choose the table top of the CNC Router according to the material of the workpiece and the processing technology. It is worth noting that BuyCNC upgraded the traditional CNC Router vacuum table and added aluminum T-slot profiles to the CNC Router vacuum table, so that the table has the advantages of both vacuum and T-slot.

As a professional woodworking CNC router with vacuum table machine, this machine body is welded by thick steel pipes, so it is enough strong to process different materials. And it has many advanced kit such as Hiwin linear rails and bearings, Germany precision helical racks on the X and Y axes etc. It is worth mentioning that the powerful CNC vacuum pump of the CNC router for sale machine can vacuum the material within 3 seconds. This greatly improves the work efficiency of woodworking CNC router machine.

3.Plate and process suitable for CNC Router vacuum table.

Thin or irregularly shaped workpieces. The profiled tabletop cannot fix the workpiece on the Aluminum T-slot table, but the CNC Router Vacuum Table can tightly adsorb the rough workpiece on the tabletop. During the cutting process, vibration will not affect the cutting effect. The CNC Router vacuum table will improve the cutting accuracy to a certain extent, especially for lighter or irregular plates. Suppose this kind of scale is fixed with a clamp. In that case, it may cause a small displacement due to the machine vibration during the cutting process, thereby affecting the cutting’s accuracy, and the vacuum table will not have this problem.

Line carving, modeling, slotting, and cutting of wooden doors and panel furniture. The line carving and cutting processing time of wooden doors or panel furniture are high-speed, and they can be processed in about a few minutes. If you use an Aluminum T-slot table, workers need to spend a few minutes fixing the board, which is not a good choice. But with CNC Router Vacuum Table, it only takes ten seconds to set the workpiece. From the perspective of efficiency, the carving of lines and the cutting of panel furniture are more suitable for choosing CNC Router Vacuum Table.

4.Material and process suitable for T-slot table.

Too thick material. The CNC Router Vacuum Table is not suitable for is thicker wood. Such a board itself is heavy enough, and vacuum adsorption is a bit laborious. It only needs to be fixed by a fixture to ensure that there will be no displacement that affects the cutting accuracy too much. It is not necessary to use a CNC Router vacuum table.

Relief prints. Generally speaking, it takes a long time for embossing to be finished. A sheet may need to be engraved for a whole day or longer, so there is no need to consider the manual fixation which takes a few minutes longer than vacuum table. Generally speaking, It should be regarded as more economically. The vacuum adsorption pump’s power is 5.5kw/h, which means that it consumes 5.5kw of electricity per hour. If you work for 8 hours a day, you need to finish 8×5.5=44kw of electricity. The relief work is more suitable for CNC Router with a Aluminum T-slot table rather than a vacuum table.

Open cutting. The workpiece needs to be hollowed out. As air enters the hollowed-out part, the plate cannot be vacuum absorbed. Therefore, it is not recommended to use a CNC Router vacuum table for products like hollow partitions and screens.

This is a small 4×4 CNC router machine, its shape is small and exquisite, the 4×4 wood CNC machine has a variety of advanced cnc router kit 4×4, such as German precision helical racks on the X and Y axes, with TBI ballscrew Z axis drive, brushless microstepper motors and so on. Meanwhile, Our 4×4 router table machine is very easy to learn and use. You can quickly complete the assembly of the machine and use it.

5. How many partitions do the CNC Router Vacuum Table consist of?

For the partition of the CNC Router Vacuum Table, the most common are four partitions, six partitions, or eight partitions. Each control valve controls a small section. The advantage of this design is that if the fixed workpiece is relatively small, it is unnecessary to open all the control valves. All the suction power is concentrated in this small partition so that the adsorption force is more vital. For customers who often adsorb small workpieces, it is more suitable to choose 6 or 8 sections.

6.For different sizes of CNC Router Vacuum Table, what power should I choose?

| Size of CNC Router Vacuum Table | Vacuum Pump Power |

| 1300x1300mm (4x4ft) | 2.2KW |

| 1300x2500mm(4x8ft) | 5.5KW |

| 1500x3000mm(4x8ft) | 7.5KW |

| 2000x3000mm(4x8ft) | 7.5KW |

| 2000x4000mm(4x8ft) | 5.5kw X 2 sets |

| 2000x6000mm | 7.5kw X 2 sets |

7. Why is it necessary to lay another thin plate on the CNC Router Vacuum Table's surface?

Generally speaking, the workpiece is not directly placed on the CNC Router Vacuum Table, but a layer of the thin plate is first laid on the surface of the CNC Router Vacuum Table, and then the workpiece is placed on the thin plate. Why do you want to do this? The purpose of this is to protect the CNC Router Vacuum Table and prevent Router bits from hurting the CNC Router Vacuum Table. The layer of thin board placed can be MDF board or Aosong board, because MDF board or Aosong board is not airtight, it is formed by wood fiber and glue under high pressure, wood fiber itself and wood fiber There are ducts or gaps between them, so the MDF board or the Ozon board still has a certain degree of air permeability. The pressure of the workpiece at the position close to the density board is much lower than the atmospheric pressure on the other side, forming an opposing force. The workpiece and the thin plate are tightly adsorbed to the CNC Router Vacuum Table so that no displacement occurs.

8. Analysis of the reasons for the weak suction of CNC Router Vacuum Table.

The weak suction of the CNC Router Vacuum Table may cause air leakage due to the reduced tightness of the vacuum pipe.

If you find such problems, you can try the following solutions:

1) Check the valve connection of the vacuum pipeline to see if there is any leakage;

2) Check the CNC Router Vacuum Table to see if the CNC Router Vacuum Table is uneven;

3) Check whether the motor circuit voltage is normal, and change the direction of motor rotation;

4) If the vacuum pump used by the machine is a water circulation vacuum pump, please check whether the water in the pump is too little,

5) Check whether the motor of the vacuum pump is stuck or rusted. If so, please remove the rotating shaft of the motor fan guard net.

6) Check the filter plug in the vacuum pump and clean the filter plug in time.

7) Add a thin density board between the CNC Router Vacuum Table and the workpiece.

Just as BuyCNC has always emphasized, when customers buy CNC Routers, they should not buy the most expensive or cheapest, but should choose the one that suits them best. Only the most suitable one is the real best CNC router machine for the customer.

If you need more information, please contact us on line or contact as following:

Email: [email protected]

Whatsapp: +8618615409281