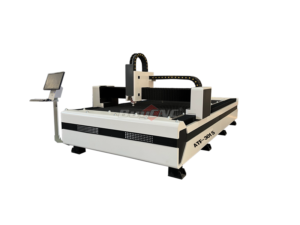

Fiber Laser Cutting Machine for Metal

BuyCNC Fiber Laser Cutting Machine

Fiber laser cutting technology is a high-tech technology developed in recent decades. Compared with traditional mechanical cutting technology, fiber laser cutting technology has higher cutting accuracy, lower roughness, higher material utilization, and production efficiency. Especially for high cutting requirements, fiber laser cutting technology is the best choice. So, how to choose a good fiber laser cutting machine correctly in 2021? I guess the following must be what you want to know.

1. What is a fiber laser cutting machine?

Fiber laser cutting technology is a non-contact, high-speed, high-precision cutting method using high-density energy. Specifically, the fiber laser cutting machine realizes automatic cutting by moving the laser beam's irradiation position on the material under the CNC controller system's control. In this process, the most important accessory is the fiber laser. The fiber laser outputs a high-density laser beam. It gathers it on the material's surface so that the area irradiated by the ultra-fine focus spot on the material is instantly melted and vaporized to realize cutting. The traditional CO2 cutting machine's principle is to spread the light path based on the copper mirror reflection. In this way, the optical path attenuation is fast, the optical path requirements are high, and the energy loss is more. The excitation of CO2 generates the laser, and the conversion rate of electro-optical is low. The emergence of fiber laser cutting machine has improved production efficiency and provided a new idea for the fiber laser cutting industry.2. What is a fiber laser cutting machine used for?

Application industry of fiber laser cutting machine.The fiber laser cutting machine's application field is vast, covering almost the entire manufacturing and processing industry, which is one of the reasons why traditional manufacturers prefer fiber laser cutting machine. For example, sheet metal processing, aerospace, auto parts, food machinery, precision parts, electronic parts, craft gifts, decorative advertisements, household appliances, kitchen utensils, cabinets, hardware, elevators, etc.

Processing materials of fiber laser cutting machine.

Fiber laser cutting machines are often used for metal processing. For example, stainless steel, alloy steel, carbon steel, gold, silver, copper, iron plate, aluminum, aluminum alloy, silicon steel, etc. Besides, the fiber laser cutting machine equipped with a rotating shaft can process some metal pipes. It can be said that the processing materials of fiber laser cutting machines are still vibrant. You need to choose a reasonable fiber cutting machine for the material to be processed in your actual purchase.

3. What are the advantages of a fiber laser cutting machine?

1. High cutting accuracy and fast cutting speed.The cutting precision of the fiber laser cutting machine is high. When the accuracy is up to 0.05 mm, the speed can reach 10 m/min.

2. The cutting surface is smooth and no-burrs.

The fiber laser cutting machine's cutting surface is smooth, and the cutting surface is no- burrs. And the processed material does not require secondary processing. The roughness of the cutting table is minimal, generally less than Ra6.5.

3. Small cuts on the surface of the material.

Because the laser-focused spot is tiny, the material will soon be melted or vaporized once the high-density energy touches the processed material, thereby forming holes. In this process, the fiber laser head does not directly touch the surface of the material. Therefore, the hole gap will be very narrow, and the width of the cut will not be greater than 0.20mm.

4. Good cutting quality of the material.

The non-contact processing of the fiber laser cutting machine and the material makes the cutting edge less affected by high-density energy heat. Therefore, there is no thermal deformation of the material, and the processed material does not require secondary processing.

5. Save processing cost.

Fiber laser processing does not require abrasive tools, saving the time of repairing and replacing abrasive tools. The fiber laser cutting machine also realizes the cutting of different materials through the CNC mechanical system's control. Therefore, materials are saved, and the utilization rate of materials is improved.

6. Safety and environmental protection.

The fiber laser cutting machine produces less waste and low noise, which greatly improves the workers' working environment. Besides, the fiber laser cutting machine has high safety performance, safety, and pollution-free, which is your best choice.

4. How much does it cost to buy a fiber laser cutting machine?

Many factors affect the price of fiber laser cutting machines. Due to different brands, powers, and configurations of fiber laser cutting machine, the price will fluctuate greatly. Generally speaking, the price of a fiber laser cutting machine is between 20,000 and 150,000 USD. We recommend that you only need to make a reasonable choice according to the material, thickness, format, and budget that you need to cut. Consult Now to obtain the material thickness table of the fiber laser cutting machine.5.How to buy a fiber laser cutter from China?

1.Consult:We will recommend you the most suitable fiber laser cutting system after getting your inquiry.

2.Quotation:

We will offer you with our detailed quotation proposal according to the your special requirement about the fiber laser cutter machine. You will get the most suitable specifications, the best accessories and the affordable price in your budget.

3.Process Evaluation:

Both sides carefully evaluate and discuss all the details (technical parameters, specifications and business terms) of the order to exclude any misunderstanding.

4.Placing Order:

If you have no doubt, we will send you the PI (Proforma Invoice), and then we will sign a contract with you.

5.Production:

We will arrange the production of the fiber laser cutter once we get the advance deposit. The latest news about production will be updated and informed to the buyer during the machine production.

6.Quality Control:

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be fully tested to make sure the fiber laser cutter can work well before delivery.

7.Delivery:

BuyCNC will arrange the delivery as the terms in the contract after the confirmation by the buyer.

8.Custom Clearance:

We will supply and deliver all the necessary shipping documents to the buyer and ensure a smooth customs clearance.

9.Service and Support:

BuyCNC will offer professional technical support and in-time fiber laser cutting service by Phone, Email, Skype, WhatsApp, Online Live Chat, Remote Service. We also have door-to-door service in some areas.

6. Choose the correct supplier of fiber laser cutting machine.

BuyCNC Co., Ltd is a high-tech manufacturing company located in Jinan, China. We develop, produce, and sell industrial laser equipment such as fiber laser cutting machines. The fiber laser cutting machine produced by BuyCNC has been sold to many countries and regions, including America, Europe, Asia, South Africa, etc. And has received unanimous praise. BuyCNC Co., Ltd has a professional after-sales service team that can provide after-sales support such as machine installation and commissioning. Of course, if you want, we can provide local installation training. We have studied fiber laser equipment for many years and will invest a lot of money in the future to support the development of fiber laser cutter. BuyCNC will be your best choice.Read more

Showing 1–12 of 32 results