BuyCNC Fiber Laser Cutting Machine

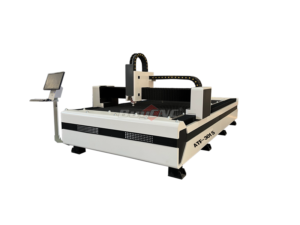

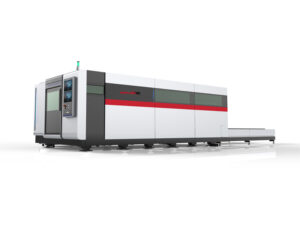

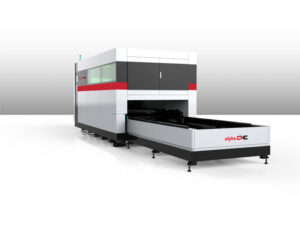

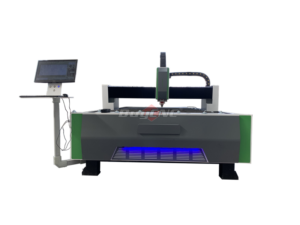

CNC Fiber Laser Cutting Machine For Sale

Related Article about Fiber Laser Cutting Machine for metal

BuyCNC 12000w Fiber Laser Cutting Machine Shipped Successfully

BuyCNC

Laser Cutter For Metal Signs Help Advertising Industry

Laser

Why Choose China Fiber Laser Cutting Machine Manufacturer

Why

1.What is a fiber laser cutter?

Fiber laser cutter is a CNC laser cutting system for metal, which is with high cutting quality, high cutting speed, high cutting precision and high cutting efficiency. It is suitable for most of of metal cutting and the fiber laser cutting machine is your good partner in metal processing. Equipped with different power (from 1,000W to 30,000w), it is used to cut metal materials with different thickness, such as stainless steel, carbon steel, electrical steel, galvanized steel, aluminum zinc plate, aluminum, aluminum alloy, titanium alloy, copper, brass, iron, etc. Fiber laser cutting machine is also called fiber laser metal cutting machine, fiber laser cutting machine, fiber laser cutting system, fiber laser cutting equipment, metal laser cutting machine, fiber optic laser cutter, laser metal cutter, laser cutter machine for metal, CNC laser cutter, CNC laser cutting machine, cnc laser metal cutter, fiber optic laser cutting machine.

2.What is a fiber laser generator?

The Fiber laser generator is used in the fiber optic laser cutter, and it a laser generator with rare earth doped glass fiber as gain medium. The pump light of the fiber optic laser generator is used to irradiate the glass fiber pump source doped with rare earth elements, which stimulates the absorption of photons by rare earth ions. The excitation radiation is the same as the incident photon frequency, and the propagation direction coherent light and vibration direction are amplified by light to generate high-energy laser.

Fiber laser generator has a wide range of applications, such as the material processing, medical beauty, communication, instruments and sensors, scientific research and military, etc. The largest field of fiber optic laser application, material processing has developed many application technologies such as laser cutting marking, welding, cleaning and surface treatment, and cladding.

Fiber laser cutting industry has become the most widely used field for fiber laser technology. Because the working medium of optical fiber laser generator is optical fiber, its characteristics are affected by the transition characteristics of optical fiber. The fiber laser pump light entering the optical fiber generally has a variety of modes, and the signal photoelectric may have a variety of modes. Different fiber laser pump modes have different effects on different signal modes, which makes the analysis of fiber laser generator and amplifier more complex. The doping distribution in the optical fiber also has a great influence on the fiber laser generator. In order to make the medium have gain characteristics, working ions (i.e. impurities) are doped into the optical fiber laser.

Generally, the working ions are evenly distributed in the core. However, the distribution of different modes of pump light in the fiber is uneven. In order to improve the pumping efficiency of the fiber laser, the ion distribution and pumping energy distribution should be as close as possible. When analyzing the optical fiber laser generator, in addition to the general principle of the laser generator discussed above, we should also consider its own characteristics, introduce different models and adopt special analysis methods to achieve good analysis results.

Like the traditional solid and gas laser generator, the fiber laser generator is also composed of three basic components: pump source, gain medium and resonator. The pump source of the fiber optic laser generally adopts high-power semiconductor laser generator, and the gain medium is rare earth doped fiber or ordinary nonlinear fiber. The resonator can be composed of various linear resonators such as fiber grating and optical feedback element, or various linear resonators can be composed of couplers. An annular cavity.

The pump light of the fiber optic laser is coupled to the gain fiber through an appropriate optical system. After absorbing the pump light, the gain fiber forms particle number inversion or nonlinear gain to produce spontaneous emission. The generated spontaneous emission light forms a stable laser output through the excitation amplification and mode selection of the resonator.

3.How does the fiber laser cutting machine work?

Through the numerical control system, the optical fiber laser cutting machine is with an optical fiber laser generator, which dopes the pump material into the optical fiber and couples the laser of specific wavelength emitted by the semiconductor laser to make the optical fiber produce laser. And then, the optical fiber laser cutter converges the laser beam into a small-diameter spot to form a high-energy density and extremely bright beam, which will act on the cut metal to make the metal temperature at the laser irradiation point rise sharply and reach the vaporization temperature instantly, causing evaporation and forming holes. The laser cutting machine takes this as the starting point and makes the fiber laser beam move relative to the workpiece according to a certain trajectory according to the shape requirements of the workpiece to be cut to form a slit. At the same time, the auxiliary blowing device is used for slag removal.

4.What are the characteristics of fiber laser cutting machine?

1. The electro-optic conversion efficiency of fiber laser metal cutting machine is high, and the conversion efficiency is more than 30%. Low power fiber lasers do not require cooling chiller. The air cooling system on the fiber laser cutting system can greatly save the power consumption during operation of the fiber laser metal cutting machine, and it will save the operation cost and achieve the highest production efficiency.

2. When the fiber laser works, it only needs the lowest maintenance cost, and no need the additional gas to the laser, so the fiber laser metal cutting machine will be with low cost for the operation and the maintenance.

3. The fiber laser metal cutting machine adopts semiconductor modular and redundant design. There is no optical lens in the resonant cavity, so the fiber laser metal cutting machine no need the no start-up time, no adjustment, maintenance and high stability. It reduces accessory costs and maintenance time.

4. The output wavelength of fiber laser metal cutting machine is 1.064 μ m, which is only 1 / 10 of CO2 wavelength. The output beam has and high power density and good laser beam quality. So it is very conducive to the absorption of metal materials.

5. The optical transmission of the whole fiber laser metal cutting machine adopts optical fiber, which does not need complex light guide systems such as mirrors. The optical path is simple, the structure is stable, and the external optical path is maintenance free.

6. The cutting head contains protective lenses, so that the consumption of expensive consumables such as focusing lenses is very small.

7. Light is output through optical fiber, which makes the design of mechanical system of the fiber laser metal cutting machine very simple and easy to integrate with robot or multi-dimensional working table.

8. After the laser is equipped with a shutter, multiple machines can work simultaneously through optical fiber shunting and multi-channel. The function expansion is convenient and the upgrade is convenient and simple.

9. The optical metal laser cutter has the advantages of small volume, light weight, movable working position and small floor area.

5.What is the fiber laser cutting machine used for?

Applications industry of the fiber laser cutting machine: sheet metal processing, electronics, advertising, aviation, aerospace, automobiles, electrical appliances, food machinery, kitchenware processing subway parts, ships, textile machinery, precision accessories, tool processing, decoration, engineering machinery, metallurgical equipment, elevators, household appliances, craft gifts, metal processing, and other industrial manufacturing industries.

Materials cut by the fiber laser cutting machine: carbon steel, iron, alloy steel, stainless steel, silicon steel, galvanized plate, spring steel, aluminum, aluminized zinc plate aluminum alloy, , pickling plate, copper, silver, gold, titanium and many other different metal plates and pipes.

6.What Are The Benefits And Advantages Of Fiber Laser Cutters?

1. High precision: the metal laser cutter positioning accuracy is 0.05mm, and re- positioning accuracy is 0.025mm.

2. Narrow slit: Because the very small light spot of the fiber laser beam, the focal point reaches a high power density, so that the material is quickly heated to the degree of vaporization, and the hole is evaporated by the high temperature. With the relatively linear movement of the beam and the metal material, the hole continuously forms a slit with a very narrow width, and the width of the slit is about 0.10-0.20 mm.

3. Smooth cutting surface: the cutting edge has no burrs, and the roughness of the cutting edge is controlled within Ra6.5.

4. High working speed: the cutting speed of the metal laser cutter can reach 30m / min, and the max. moving speed can reach 60m / min.

5. High cutting quality: The metal laser cutter belongs to non-touch cutting, so the cutting edge is affected by heat very little. The workpiece is almost no thermal deformation, and during the punching and shearing of the material, the the collapsed edge formed is completely avoided.

6. No damage to the material: the laser cutting head will not touch the surface of the material to ensure that the material is not scratched.

7. Not affected by the shape of the material: The metal laser cutter is controlled by the CNC system, so it has good flexibility, and it can process any graphics, and can cut tubes and other shaped materials.

8. No mold investment: In the past, mold were widely used in the metal processing, but laser processing requires no mold, so it will have no mold consumption, no mold repair cost, and saving mold replacement time, thereby saving processing costs and reducing production costs, especially suitable for processing large products.

9. Material saving: the metal laser cutter uses computer programming, different shapes of the products can be cut to Max. the utilization rate of the workpiece.

10. Fast speed of sample delivery: After the product drawings design are finished, the metal laser cutter can cut the material immediately, and the real new product can be obtained immediately.

11. Safety and environmental friendly: the metal laser cutter is with low waste, low noise, clean, safe and pollution-free. So the metal laser cutter greatly improves the working environment.

7.Advantages over CO2 laser cutting machine:

1. Better laser beam quality: compared with the CO2 laser cutting, the metal laser cutter is with smaller focus spot, thinner cutting line, higher work efficiency and better processing quality.

2. Higher cutting speed: The metal laser cutter is with 2-3 times cutting speed that of CO2 laser cutting machine with the same laser power.

3. Higher stability: the world’s best optical metal laser cutter is adopted, with stable performance, and the service life of main components can reach 100000 hours.

4. Higher electro-optic conversion efficiency: the photoelectric conversion efficiency of metal laser cutter is about 30%, which is three times that of CO2 laser, saving energy and environmental protection.

5. Lower using cost: the power consumption of the whole metal laser cutter is only 20-30% of that of similar CO2 laser cutting machine.

6. Lower maintenance cost: no need to use the laser working gas; Optical fiber transmission, without reflective lenses, saves much maintenance costs.

7. Easier operation and maintenance: The metal laser cutting machine adopts optical fiber transmission, there is no need to adjust the optical path.

8. More flexible light guide effect: the metal laser cutting machine is with compact structure, small size, easy to meet the requirements of flexible processing.

8.Advantages over YAG laser cutting machine:

1.Higher cutting speed: the speed of optical metal laser cutting machine is 4-5 times that of YAG, which is suitable for mass processing and production.

2.Lower operating cost: the operating cost of metal laser cutting machine is lower than that of YAG solid laser cutting machine.

3.Higher photoelectric conversion efficiency: the photoelectric conversion efficiency of metal laser cutting machine is about 10-12 times that of YAG laser cutting machine. The price of the corresponding metal laser cutting machine is higher, so the price of the metal laser cutting machine is much higher than that of YAG laser cutting machine, but much lower than that of carbon dioxide laser cutting machine. But its sex ratio is indeed the highest of them.

9.How to maintain the fiber laser cutting machine?

How to use and maintain metal laser cutting machine? Is it easy to do it? When using metal laser cutting machine to do engineering, the operator should learn the skills of use and maintenance the metal laser cutting machine, so as to give better play to the effectiveness of the equipment and maximize the efficiency of the metal laser cutting machine.

1. Check the steel strip frequently to ensure the tension of the metal laser cutting machine. Otherwise, if problems occur during operation, personal injury or even serious death may be caused.

2. Check the straightness of the track and the verticality of the machine every half a year, and repair and debug in time if any abnormality is found. Without doing this, the cutting effect may be bad, and the error will happen, which will affects the cutting quality. This is the first task and must be completed.

3. Vacuum the dust and dirt in the machine once a week. All electrical cabinets and main parts of the metal laser cutting machine shall be sealed and dustproof.

4.The guide rail of the metal laser cutting machine shall be cleaned frequently to remove dust and other sundries, so as to ensure that the metal laser cutting machine frame is cleaned frequently and lubricated without sundries. The guide rail of the metal laser cutting machine should be cleaned and lubricated frequently, and the motor of the metal laser cutting machine should also be cleaned and lubricated frequently. The fiber laser cutting machine can move better and cut more accurately in the cutting process, and the quality of cutting products will be improved.

5.Double focal length laser cutting head is a fragile product on laser cutting machine. Long term use will damage the laser cutting head.

The fiber laser cutting machine needs regular inspection and maintenance. If there is deformation or other forms, you should know that the laser cutting head has been damaged a little, and you need to replace it. Non replacement will affect the cutting quality and increase the cost. Some products may need to be reprocessed and reduce the production efficiency.

10.What should we pay attention to when using fiber laser cutting machine?

1. Ensure that the power socket is in good connection and the ground wire of the fiber optic laser cutter is reliably grounded.

2. Ensure that the working voltage of the fiber optic laser cutter ’s chiller is stable and normal.

3. Mismatched power frequency will cause damage to the fiber optic laser cutter . According to the actual situation in your country, please choose 50Hz or 60Hz.

4. In order to protect the circulating water pump, it is strictly prohibited to operate the fiber optic laser cutter without water. Empty the water storage tank before packing the new machine. Please make sure that the water tank is filled with water before starting up, otherwise it is easy to damage the water pump. When the water level of the water chiller’s water tank is lower than the green (normal) range of the water level gauge, the cooling capacity of the chiller will decrease slightly. Please ensure that the water level of the water tank is within the green (normal) range of the water level gauge. Do not use circulating pump for drainage.

5. Ensure that the air inlet and outlet channels of the chiller are unblocked. The air outlet above the chiller of the fiber optic laser cutter shall be Min.1250px away from the obstacle, and the side air inlet shall be Min. 500px away from the obstacle.

6. The air inlet filter of the fiber optic laser cutter must be cleaned regularly. The air filter of the fiber optic laser cutter should be cleaned regularly. Serious blockage of the air filter of the fiber optic laser cutter will cause failure of the chiller.

7. Please pay attention to the influence of condensate. When the water temperature is lower than the ambient temperature and the ambient humidity is high, condensate will be generated on the surface of circulating water pipe and cooled equipment. In case of the above situation, it is recommended to increase the water temperature or heat preservation treatment for water pipes and cooled equipment.

8.The fiber optic laser cutting machine is industrial equipment. Non professionals are not allowed to operate it.

11.What is the cost of fiber laser cutting machine?

The cost of fiber optic laser cutting machine consists of the following items:

1. CNC parts. They includes the machine body, fiber laser generator, fiber laser cutting head, laser regulated power supply, air compressor, chiller, air storage tank, gas cylinder,cooling dryer, filter, exhaust fan, dust collector, slag remover, etc..

2. Optical fiber laser cutting system and optical fiber laser cutting software.

3. Freight. From China to customer’s workshop.

4. Tax rate. Include the VAT, tariffs etc.

5. Customs clearance.

6. Local service and technical support.

Generally speaking, the cost of a fiber optic laser cutting machine ranges from $20,000.00USD to $200,000.00USD

Customer reviews and testimonials of CNC Laser Cutting Machine

1. Macker Chandler

From the USA

10. Oct 2021

I like this laser metal cutting machine very much, it allows me to quickly realize the metal cutting function.

2. Ronaldo Sanchez

From France

9. Oct 2021

I selected a lot of CNC laser cutting machine suppliers on the Internet, and finally, I chose BuyCNC because it is very professional.

3. Jason Wilson

From the United States

5. Oct 2021

I have been in the laser cutting industry for many years. I have always used laser machines to process sheet metal. In order to expand the scale of the factory, I bought a CNC laser cutting machine from BuyCNC some time ago. The laser cutting machine price is so attractive, it is cheaper than all the laser machines I bought before, and when I received the goods, this machine is very beautiful and its performance is also very good, I am very satisfied.

4. Jacob Muller

From Germany

3. Oct 2021

I am a newcomer to the laser cutting industry. I bought a small CNC laser cutting machine. The price of this machine is very cheap, and the delivery time is very fast. My machine was delivered to me smoothly and it is in BuyCNC. Under the guidance of our engineers, I assembled the machine and performed my first attempt at laser cutting perfectly.

5. Noval Lisbon

From Spanish

23. Sep 2021

I bought the fiber laser cutting machine in March, and I received the goods in May, and now this machine is working for me.

6. Betis Noel

From Finland

20. Sep 2021

In order to be able to process my steel, I bought a small laser metal cutting machine. This small laser cutting machine can cut these steels very well.

7. Chris Johnson

From the UK

15. Sep 2021

My friend recommended BuyCNC for me. The CNC laser cutting machine he bought here is of high quality, and I am very satisfied with this machine.

8. Jefferson Williams

From the USA

12. Sep 2021

The price of this fiber laser cutting machine is very affordable, thousands of dollars cheaper than my friend’s price, and the processing quality is also very good.

9. Daniel Smith

From Canada

10. Sep 2021

I used to buy CNC laser cutting machinery from other laser engraving machine manufacturers in China, but it is not as good as the laser engraving machine I bought at BuyCNC.

10. Mendy Cole Chrislovsky

From Russian

4. Sep 2021

I recently commissioned my new 4×8 laser metal cutting machine, and I am very satisfied with the performance of this machine.

11. Giannis Kumbo

From Greece

1. Sep 2021

I bought a 1000w laser metal cutting machine. Because of the good performance of this machine, I have gained more customers.

12. Barrett Carson

From Australia

29. Aug 2021

I like this 2000w CNC laser cutting machine very much. My workers can quickly operate this machine, and the work efficiency of this new machine is twice that of the old machine.

13. Stevenson Learson

From the UK

26. Aug 2021

I found BuyCNC’s official website on Alibaba. Their sheet metal cutting machine looks very good. I have already paid the deposit and am waiting for delivery.

14. Martinez Eric

From Spanish

22. Aug 2021

This is the third machine I bought at BuyCNC. I bought a CNC engraving machine two times before. This time I bought a CNC laser cutting machine. They gave me a discounted price, which saved me a lot of money.

15. George Walker

From the USA

20. Aug 2021

As a newcomer in the CNC laser cutting machine industry, I chose many kinds of machines, and finally, I chose BuyCNC’s CNC laser

cutting machine because their customer service is very professional.

16. Brownie Battier

From Canada

13. Aug 2021

I received the CNC laser cutting machine I purchased two months after the payment. I successfully completed the assembly and debugging of the machine with the help of the engineer.

17. Charles Jefferson

From UK

10. Aug 2021

Because my budget is not too much, so I bought a small CNC laser cutting machine, this laser metal cutting machine can meet my needs.

18. Andre Blake

From Iceland

5. Aug 2021

I am a customer from Iceland. When I bought this fiber laser cutting machine, I was still worried about whether it could be delivered to my port smoothly, but in the end, it proved that these concerns were wrong, and my machine was delivered quickly. Arrived at my factory.

19. Richard Jackson

From Australia

1. Aug 2021

I like this laser metal cutting machine very much. My Chinese-made laser cutting machine has brought me huge profits.

20. Bruce Jackson

From Australia

1. Aug 2021

I sent the pictures of the machine I bought at BuyCNC to my local laser cutting machine manufacturer. Their laser metal cutting machine price is more than $5,000 more expensive than BuyCNC.