Table of Contents

In modern industrial production, the pursuit of efficient and precise production processes has become the core competitiveness of enterprises. With the continuous advancement of science and technology, various processing equipment are constantly being upgraded to meet the market’s demand for efficient and high-quality products. machine for woodworking, as a kind of processing equipment widely used in many industries, its performance in mass production and automated operation is particularly interesting.

Advantages of mass production of machines for woodworking

First of all, from the perspective of mass production, machines for woodworking have unique advantages. Its high precision and high speed allow it to process a large number of identical or similar products in a short period of time. Through programming and parameter settings, the machine for woodworking can automatically complete a series of complex processing actions, thus realizing the automation of mass production. This automated production method not only greatly improves production efficiency, but also reduces labor costs, allowing enterprises to occupy an advantageous position in the fierce market competition.

Automated operation of machine for woodworking

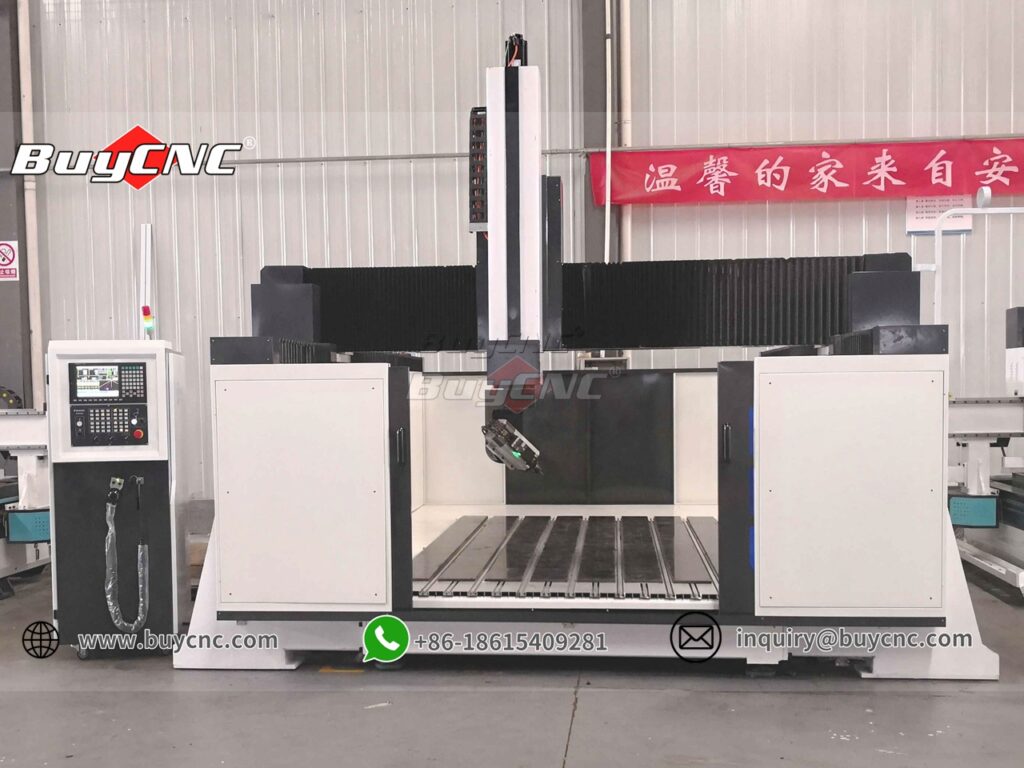

In addition, the automated operation of the machine for woodworking also provides strong support for its application in mass production. Modern machines for woodworking are usually equipped with advanced CNC systems and automation devices, which can achieve precise control of the processing process. From the positioning and processing of materials to the cutting of finished products, the machine for woodworking can automatically complete it without excessive manual intervention. This automated operation not only improves production efficiency, but also reduces the impact of human factors on processing quality, ensuring product consistency and stability.

It is worth mentioning that with the continuous advancement of technology, the degree of automation of machines for woodworking is also constantly improving. Some high-end machines for woodworking have implemented functions such as intelligent identification, automatic tool changing, and automatic detection, further improving the level of their automated operations. The introduction of these functions not only makes the machine for woodworking more convenient in mass production and automated operations, but also provides enterprises with more flexible and efficient processing solutions.

Suitable machine for woodworking and supporting equipment

However, to achieve mass production and automated operation of machines for woodworking, some key factors need to be paid attention to. First of all, it is crucial to choose the right machine for woodworking and supporting equipment. Different machines for woodworking have differences in performance, functions and scope of application, so you need to choose according to production needs. Secondly, formulating reasonable processing plans and processes is also key. By optimizing and adjusting the processing process, production efficiency and quality can be further improved. In addition, the training and management of operating personnel cannot be ignored. They need to be proficient in the operation skills and maintenance methods of machines for woodworking to ensure the normal operation of the equipment and efficient production.

In addition to the above factors, companies also need to consider how to integrate and coordinate the machine for woodworking with other production equipment. By building an intelligent production line or automated workshop, seamless connection and collaborative work between equipment can be achieved, further improving production efficiency and reducing costs.

To sum up, machines for woodworking have significant advantages in mass production and automated operations. By selecting appropriate equipment, formulating reasonable processing plans, and training qualified operators, companies can make full use of the efficient and precise features of machines for woodworking to achieve automation and efficiency in mass production. This will help improve the production efficiency of enterprises, reduce costs and enhance market competitiveness, and provide strong support for the sustainable development of enterprises.