Table of Contents

Why laser rust cleaner machine are popular

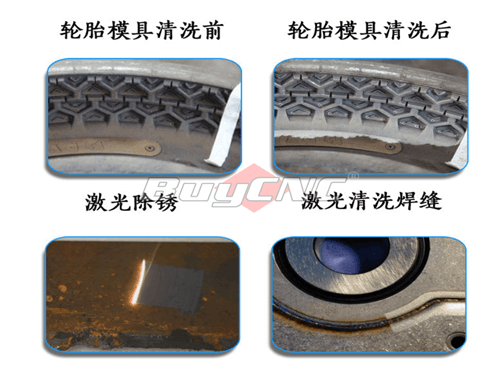

As people have paid more and more attention to environmental protection and pollution industries, traditional and backward cleaning methods have become more and more unable to meet people’s needs. With the advancement of technology, people have gradually explored various technologies that are conducive to environmental protection, and laser cleaning technology is one of them. Laser rust cleaner for sale is a kind of workpiece surface cleaning machine that has been newly applied in the past ten years. This fiber laser rust removal machine is gradually replacing the traditional cleaning process in many fields with its own advantages and irreplaceability.

Traditional cleaning methods include mechanical cleaning, chemical cleaning, and ultrasonic cleaning. The mechanical cleaning method uses mechanical means such as scratching, rubbing, brushing, and sandblasting to remove dirt; wet chemical cleaning uses organic cleaning agents to pass Spray, drench, soak or high-frequency vibration to remove surface attachments; ultrasonic cleaning method is to put the processed parts into the cleaning agent, and use the vibration effect of ultrasonic to remove dirt. At present, these three cleaning methods are still used by many people, but the three methods all produce pollutants to varying degrees, and their application is greatly restricted under the requirements of environmental protection and high precision.

How to use laser rust cleaner for sale

The fiber laser rust removal machine refers to the use of high-energy and high-frequency laser beams to irradiate the surface of the workpiece to cause the dirt, rust or coating on the surface to evaporate or peel instantly, and effectively remove the adhesion or face coating on the surface of the cleaning object at a high speed, so as to achieve Clean laser process. The rust cleaning laser for sale is characterized by high directivity, monochromaticity, high coherence and high brightness. Through the focus of the lens and the Q switch, the energy can be concentrated into a small space and time range. Subdivided from the method, The rust cleaning laser for sale has four cleaning methods:

1. Laser dry cleaning method: that is, the fiber laser rust removal machine is used to decontaminate stains by pulsed laser direct radiation.

2. Laser + liquid film method: first deposit a layer of liquid film on the surface of the substrate, and then use laser radiation to decontaminate; when the laser emitted by the laser rust cleaner for sale is irradiated on the liquid film, the liquid film is heated rapidly, causing explosiveness Vaporization and explosive shock waves loosen the dirt on the surface of the substrate. And fly away from the surface of the processed object with the shock wave to achieve the purpose of decontamination.

3. The method of laser + inert gas: that is, while cleaning the stains with laser radiation with rust cleaning laser for sale, blow the inert gas to the surface of the substrate. When the dirt is peeled from the surface, it will be blown off the surface by the gas immediately to avoid The surface is contaminated and oxidized again;

4. Use the fiber laser rust removal machine to loosen the dirt, and then clean it with non-corrosive chemical methods. At present, due to the development of my country’s high-end manufacturing industry and the continuous improvement of environmental protection requirements, traditional cleaning technologies (chemical methods, mechanical polishing methods) are far from meeting the needs of my country’s industrial production, and the backwardness of cleaning technology restricts the normal production and operation of some important industries in my country. Therefore, The laser rust removal gun for sale, as a representative of green and efficient manufacturing, has a broad market scale under the rapid development of my country’s high-end manufacturing industry.

Compared with traditional cleaning machines, laser rust removal gun for sale is a “green” cleaning method with incomparable advantages: no chemicals and cleaning fluids are required, and the cleaned waste is basically solid powder. Small size, easy to store, can be absorbed and recycled, no photochemical reaction, no noise and environmental pollution, and at the same time does not harm the health of the operator, easy to realize automatic control, and realize remote remote control cleaning.

Precautions for using laser cleaning machine

Today, when environmental protection is promoted, the laser rust cleaner machine has the characteristics of non-contact, no thermal effect, and no mechanical force on the surface of the cleaning object. The application in the industry is more extensive, so what should be paid attention to when using the laser rust cleaner machine?

1. Follow the power-on sequence of the fiber laser rust removal machine: turn on the water pump (water cooler) first, then turn on the power switch, and then turn on the laser switch. When shutting down, turn off the laser switch first, then turn off the power switch, and then turn off the water pump (water cooler).It is the most important thing for the laser rust cleaner for sale.

2. Clean the laser machine chiller regularly every half a month, drain the machine’s internal water, and fill it with new pure water (the dirty water will affect the light output effect). It can imporve the efficiency of this fiber laser rust removal machine.

3. It is required to clean regularly and quantitatively every day, remove the debris on the table, stopper and guide rail, and spray lubricating oil on the guide rail.This can make the laser rust cleaner for sale work more smoothly and avoid the occurrence of malfunctions.

4. The reflector and focusing lens should be scrubbed with a special cleaning liquid every 6-8 hours. When scrubbing, use a cotton swab or cotton swab dipped in the cleaning liquid to scrub from the center of the focusing lens to the edge in a counterclockwise direction. At the same time, be careful to prevent scratches. lens.The reflector and focusing lens is very important of the laser rust cleaner for sale.

5. Cleaning method for exhaust fan and smoke pipe: when there is a large amount of smoke and dust during processing, the fan needs to be cleaned, the outer cover of the fan is removed, and the dust on the fan blades and the air passage is scraped with thin wood, and then blown with a high-pressure gun Net dust, the method of cleaning the smoke pipe is the same as the method of water cleaning of the exhaust fan.Then the laser rust cleaner for sale can have a long working time.

During the operation of the laser rust cleaner for sale, a large amount of corrosive dust and smoke will be generated during the processing of the processed parts. These smoke and dust will be deposited on the surface of the guide rail and linear shaft for a long time, which has a great influence on the processing accuracy of the fiber laser rust cleaner for sale. And will form corrosion points on the surface of the linear axis of the guide rail, shortening the service life of the equipment. In order to make the machine work normally and stably and ensure the processing quality of the products, the daily maintenance of the guide rail and linear axis must be done carefully.