Table of Contents

Status of Mold Cleaning Industry

Do you know what is mold? A mold is a variety of molds and tools used in industrial production to obtain the required products by injection molding, blow molding, extrusion, die-casting or forging molding, smelting, stamping, and other methods. In short, a mold is a tool used to make molded objects. This tool is composed of various parts, and different molds are composed of different parts. It mainly realizes the processing of the shape of the article through the change of the physical state of the formed material. Known as the “Mother of Industry”. Through the mold, we can produce a variety of similar products in large quantities.

The mold generally includes two parts: a movable mold and a fixed mold (or a convex mold and a concave mold), which can be separated or combined. The mold is repeatedly used under high pressure and high-temperature conditions and is inevitably contaminated by the comprehensive deposition of rubber, compounding agents, and release agents used in the vulcanization process (the main pollutants are sulfides, inorganic oxides, silicone oil, carbon Black, etc.), patterns, grooves, etc. are easy to accumulate rubber and residues. When they accumulate to a certain extent, they will affect the surface shape of the mold, which will make the product a defective or waste product. Therefore, the mold must be cleaned frequently to ensure its surface The cleanliness can guarantee the quality of production and the life of the mold

However, if the traditional cleaning methods, such as chemical cleaning agent cleaning method, the high-pressure water cleaning method, dry ice method, etc., are used to clean the mold, it is gradually out of date, because these methods have many disadvantages, such as the low cleaning efficiency of these methods. , The labor intensity is high, the safety factor is low, and the cost is high. Therefore, the mold cleaning industry needs a low-cost, high-efficiency cleaning technology. Then the laser metal cleaning machine has become the most suitable machine for mold cleaning because it is more efficient, more convenient, and simpler than traditional cleaning methods.

Why choose to clean the mold with a laser cleaning machine

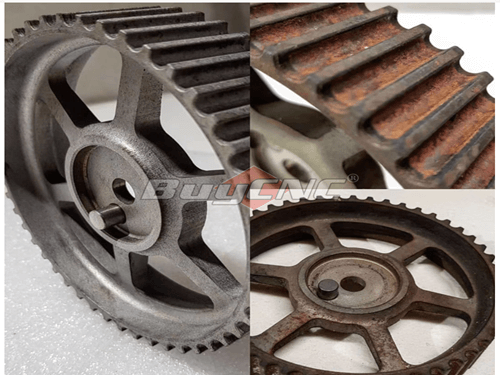

The laser metal cleaning machine can quickly remove the glue layer, oil stains, etc. on the mold surface when cleaning the mold. For uneven molds, wherever the laser is irradiated, the laser can be cleaned, and the cleaning process can be handled freely. This mold was cleaned with a portable laser cleaner. It can be seen that the cleaning effect is very obvious, there are no consumables, and no waste is generated.

The 1000w laser rust remover can not only be used to clean organic pollutants but also inorganic substances, including mold cleaning, weapon equipment, aircraft old paint cleaning, metal corrosion cleaning, etc. The technology is very mature, now the Laser metal cleaning machine has been widely used in many industries.

The laser beam generated by the portable laser cleaner will only react with the attachments on the workpiece, and will not react with the metal part itself, so there is no need to worry about the laser causing damage to the mold surface. The slightly recessed part can also be cleaned. As long as the laser cleaning is where the laser can reach, the attachments on the workpiece can be cleaned. Therefore, the portable laser cleaner has great advantages compared with other cleaning methods.

The advantages of the laser metal cleaning machine

1. More environmentally friendly: no chemicals and cleaning fluids are required. The cleaned waste is basically solid powder, small in size, easy to store, recyclable, no photochemical reaction, and no pollution.

2. Good effect: The portable laser cleaner is non-abrasive, non-contact, and non-thermal. It will not produce a mechanical force on the object to be cleaned, will not damage the surface of the object, will not damage the substrate, and will not cause secondary pollution.

3. Easy to control: The laser emitted by 1000w laser rust remover can be transmitted through optical fiber, and it can be used with robots to realize long-distance operation. It can clean complex parts that are difficult to reach by traditional methods. This feature also makes operators in some dangerous places. The safety is more guaranteed.

4. Wide use: 1000w laser rust remover can remove various types of contaminants on the surface of various materials to achieve the cleanliness that cannot be achieved by conventional cleaning. It can also selectively clean the contaminants on the surface of the material without damaging the surface material.

5. Low cost: 1000w laser rust remover has a high initial investment, but it can be used stably for a long time, with a service life of up to 10 years, low operating cost, fast speed, high efficiency, time-saving, and a return investment soon. In the long run , The cost is lower than traditional cleaning methods.

The practical application of laser metal cleaning machine in the mold industry

With the continuous progress of society, the appearance of The 1000w laser rust remover has brought ideal cleaning effects for the mold industry to clean, remove stains, stains, and rust. The traditional cleaning methods cause great losses to the mold industry, cost a lot, and clean. After a period of time, stains will still occur again, so the laser cleaning machine has won unanimous praise in the mold industry. The portable laser cleaner has no pollution and has very little wear on the mold, which can achieve zero wear. For the traditional cleaning method, the portable laser cleaner is expensive in the early stage, and there is no maintenance cost in the later stage.

As for the tire industry, which often uses molds to produce tires, there is the greatest demand for high-quality cleaning of molds, because tire molds have patterns and logo patterns. These are relatively delicate engraving processes, so the patterns of the mold are required to be very accurate. . However, the mold is repeatedly used under high pressure and high-temperature conditions, and it is inevitably contaminated by the comprehensive deposition of rubber, compounding agents, and release agents used in the vulcanization process (the main pollutants are sulfides, inorganic oxides, silicone oil, Carbon black, etc.), patterns, grooves, etc. are easy to accumulate rubber and residues. When they accumulate to a certain extent, they will affect the surface shape of the tire, which will cause the product to become defective or waste. Therefore, it must be cleaned with a laser cleaning machine frequently. Only by ensuring the cleanliness of the surface of the mold can the quality of the tire and the life of the mold be guaranteed.

Compared with traditional cleaning methods including high-pressure water spray, ultrasonic, chemical cleaning, or carbon dioxide cleaning, these methods generally require the hot mold to be cleaned after hours of laser cooling. Moreover, these methods take a long time to clean and easily damage the accuracy of the mold. Chemical solvents and noise can also cause safety and environmental issues.

If we use a portable laser cleaner to clean, because the laser can be transmitted by optical fiber, the cleaning speed is faster when in use. Not only that, because the laser cleaning machine can be connected with optical fiber, the laser can be conducted to the dead corner of the mold or the part that is not easy to clean. It can be cleaned, so it is easy to use; because the rubber is not vaporized, it will not produce toxic gases and affect the safety of the working environment. This can greatly improve the service life and quality of tire molds. In addition to the tire mold industry, there are many industries that have begun to use laser metal cleaning machines to replace traditional cleaning methods, such as the precision machinery industry, aviation industry, shipbuilding industry, military industry, automobile manufacturing industry, and so on.

BuyCNC’s laser metal cleaning machine is a new generation of high-tech surface treatment products, easy to install, operate and realize automation. The structure is compact, light and durable, and easy to operate. Pollution-free cleaning can be carried out for oil stains, rust, coatings, coatings, paints, surface oxides, etc. BuyCNC’s 1000w laser rust remover is cost-effective.

If you want to know more about laser metal cleaning machines, you can leave a message directly to us.