Table of Contents

What is the CNC router tool changer machine

The CNC router tool changer machine is a large classification of CNC engraving machines, this machine is a very professional CNC processing Machine. It has an independent tool magazine. This machine supports tool change between the spindle and the tool magazine without stopping work to change the tool. The specific meaning is that when a tool completes its process, the new tool needed for the next process will be automatically replaced on the spindle.

This not only increases the processing speed of the machine, but also improves the processing quality of the machine. Especially when processing complex patterns or products, sometimes multiple tools are needed, which requires CNC router tool changer machine. Therefore, the automatic tool change engraving opportunity is the final trend of the development of CNC engraving machine equipment.

What is the advantages of CNC router automatic tool changer machine

The ATC CNC router machine is an abbreviation for the CNC router automatic tool changer machine. As a professional ATC CNC machine, this machine has many advantages.

1. The automatic tool changer engraving machine can be used in various industries, such as furniture and home improvement, wooden crafts, cabinets, screens, advertising, musical instruments or precision instrument shell processing industries. And the materials that can be processed mainly include various wood, glass, plastic, acrylic, insulating materials and other non-metallic materials.

2. The automatic tool changer machine adopts the overall steel structure welding, which is tempered, so it will never be deformed. Most of this kind of engraving machines will use advanced control systems, so this machine has good quality and is easy to maintain. Multi-level 3D processing can be completed, and the work efficiency is high, and the processing, engraving and cutting processes can be realized.

3. The spindle of the auto tool changer CNC machine adopts imported spindle, which has high precision, high speed, low noise and long service life. In the process of operation, it can give full play to the advantages of the engraving machine.

4. The automatic tool changer machine can complete multiple processes at one time, such as drilling, cutting, engraving, keyhole and other processes can be completed at one time. Because the imported square linear guide is adopted, the precision is very accurate and the operation is very stable.

5. The automatic tool-changing engraving machine adopts a large-torque servo motor made in Japan, which has the advantages of low noise, high speed, and high positioning accuracy. It can bring stable power to the machine.

Working Principle of ATC CNC Machine

Today we will briefly talk about the principle of CNC router tool changer machine. As we all know, the automatic tool change system refers to a processing device that realizes the tool change requirements for continuous processing between parts. The automatic tool change system is mainly composed of a tool magazine and a tool change device.

Among them, the most widely used automatic tool change methods mainly include three types, namely, rotary tool post tool change, spindle head tool change, and automatic tool change with tool magazine And so on. The tool magazine can be vertical or horizontal. Let’s talk about the principle of automatic tool change of CNC engraving machine. Let’s take a look.

The principle of automatic tool change for CNC engraving machine (but generally the equipment with automatic tool change system is mainly a machining center, but there are also ordinary engraving machines)

As mentioned above, according to the different implementation principles, automatic tool change includes rotary tool post tool change, spindle head tool change, and automatic tool change with a tool magazine.

1.Rotary tool post tool change: similar to the indexing table, the tool post can be rotated at a fixed angle to realize the exchange of new and old tools.

2.Changing the spindle head tool change method: first place the tool on each spindle head. The spindle head is replaced by the rotation of the turret to achieve the purpose of tool replacement. These two methods have simple design, short tool change time and high reliability. The disadvantage is that the number of reserved tools is limited, especially the rigidity of the spindle system that replaces the spindle head tool change method is poor, so it is only suitable for machine tools with fewer procedures and low precision requirements.

3.Automatic tool change mode with tool magazine: It is composed of tool magazine, tool selection system, tool exchange mechanism and other parts, and the structure is more complicated. Although this method has many shortcomings in the process of tool change and complex design and manufacturing, it is widely used when processing complex parts with more processes due to its high degree of automation.

The basic requirements that the automatic tool change system should meet include:

1. Short tool change time;2. High precision of repeated positioning of the tool;3. Sufficient tool storage; 4. The tool magazine takes up less space.

The above is the entire content of the principle of automatic tool change for CNC engraving machines. I hope this article can be helpful to everyone. For other engraving machine related knowledge, please refer to other articles on this site.

How to choose the right auto tool changer CNC machine

Now with the rapid development of ATC CNC router machine, This CNC machine has been widely used in many industries. For example, in the furniture industry such as cabinets, wardrobes, and shoe cabinets, many factories use auto tool changer machines to cut, punch, slot, push, etc., and cooperate with professional furniture design splitting software, intelligent typesetting, and realize Customized production of cabinets and wardrobes. The use of CNC cutting machine to process furniture is unmatched by traditional cutting equipment in terms of processing dimensional accuracy and efficiency.

At present, there are many kinds of CNC automatic tool-changer and cutting machines on the market, such as linear automatic tool-changing and cutting machines, and disc automatic tool-changing and cutting machines. At the same time, there are four-process opener and double-spindle opener. Then, in the face of so many types of machines, how should you choose the most suitable machine? Today BuyCNC will introduce to you:

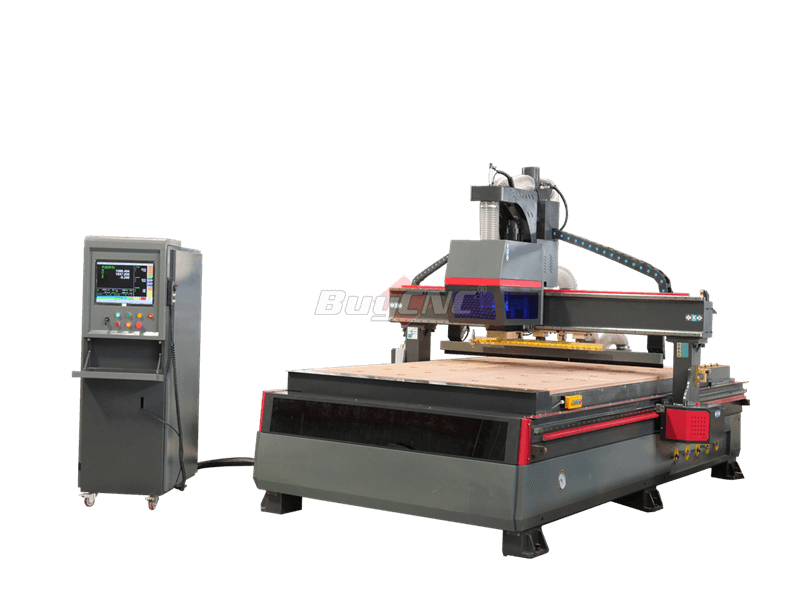

1. Straight-Linear tool changer cutting machine

This machine has a 9kw main shaft and a linear tool magazine under the beam, with a capacity of 12 tools, is a basic compound processing cutting machine that can not only process cabinets, but also produce molded door panels or carved solid wood. Automatic tool change not only saves the trouble of manual tool change, but also improves the efficiency of tool change. For cabinet processing, a row drill package can be added to improve drilling efficiency and avoid frequent tool changes.

The 12-knife in-line automatic knife changer cutting machine. This kind of cutting machine can meet most of the pre-demand of cabinet door and cabinet production and processing, including double-sided perforation and engraving of the cabinet. The 12-tools in-line tool magazine is designed to meet the complex engraving of different patterns to the utmost extent.

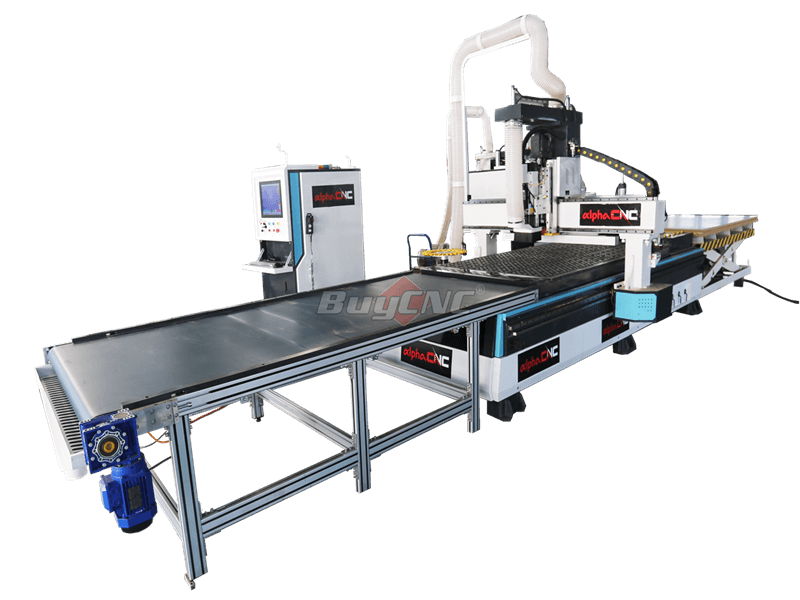

2. Disc knife changer cutting machine

This machine has a 9kw spindle and a disc tool magazine. The capacity of the tool magazine is generally 8-16 tools. Servo tool magazines can be selected, up to 32 tool positions. No matter it is cutting, grooving, or punching, it can automatically change the tool, eliminating the trouble of manual tool changing. Compared with the straight-linear machine general configuration, it is higher, the bed is stable, and the processing accuracy is high. It is more suitable for door-shaped processing.

The cabinet opening can be equipped with a drill pack to improve the drilling efficiency and avoid frequent tool changes. The disc automatic tool changer is made of heavy-duty frame and gantry frame, and the structure is solid, which can guarantee the processing accuracy to the greatest extent. The disc is used for tool change, which saves the tool change time, and the tool head can be automatically changed according to your needs. Using international imported parts, the machine has good performance and long service life.

3. Four-process cutting machine

The four-process CNC cutting machine is a relatively elementary set of cutting equipment. It has four spindles and can take care of both the door panel and the cabinet. It can be said that it is more economical for some small and medium-sized furniture companies that do not require high processing efficiency and precision. An affordable device.

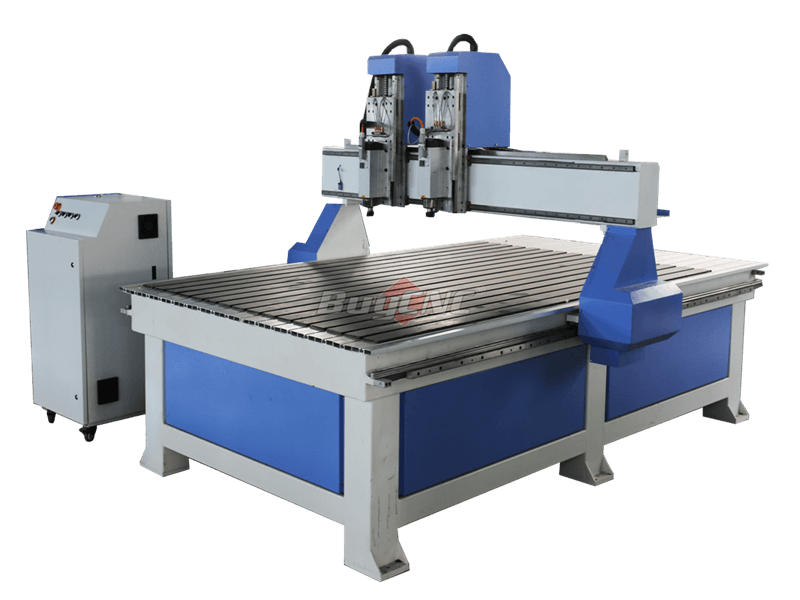

4. Double spindle cutting machine

The double-spindle cutting machine has a very fast processing speed, can realize the function of punching multiple holes at the same time, without stopping the machine to change the tool, and improving the efficiency of punching. Therefore, in the processing of cabinets, the dual-process drilling and cutting machine is faster and more accurate.

Each of these machines has the most suitable industry for processing. If you are not sure which machine is best for you, then please let us know and we will recommend the most suitable ATC CNC Machine for you.

Summary

BuyCNC has a variety of ATC CNC Router Machines for Sale. If you plan to buy an auto tool changer machine, please leave your contact information, we will contact you proactively and recommend the most suitable machine for you.