Fiber Laser Welder Video

Introduction of Laser Welding Machines

The lazer welder uses high-energy laser pulses to heat a small area of material. The energy of the laser radiation is diffused inside the material by heat transfer, causing the material to melt to form a specific molten pool.

lazer welder

fiber lazer welding

handheld lazer welder

Product Name: Lazer Welder Fiber Lazer Welding Machine Handheld Lazer Welder

Laser welding machines are widely used in mobile phone battery cases, electronic components, mobile communications, precision equipment, hardware products, auto parts, glasses, watches, jewelry, medical equipment, thermos cups, wine pots, kitchens and other industries.

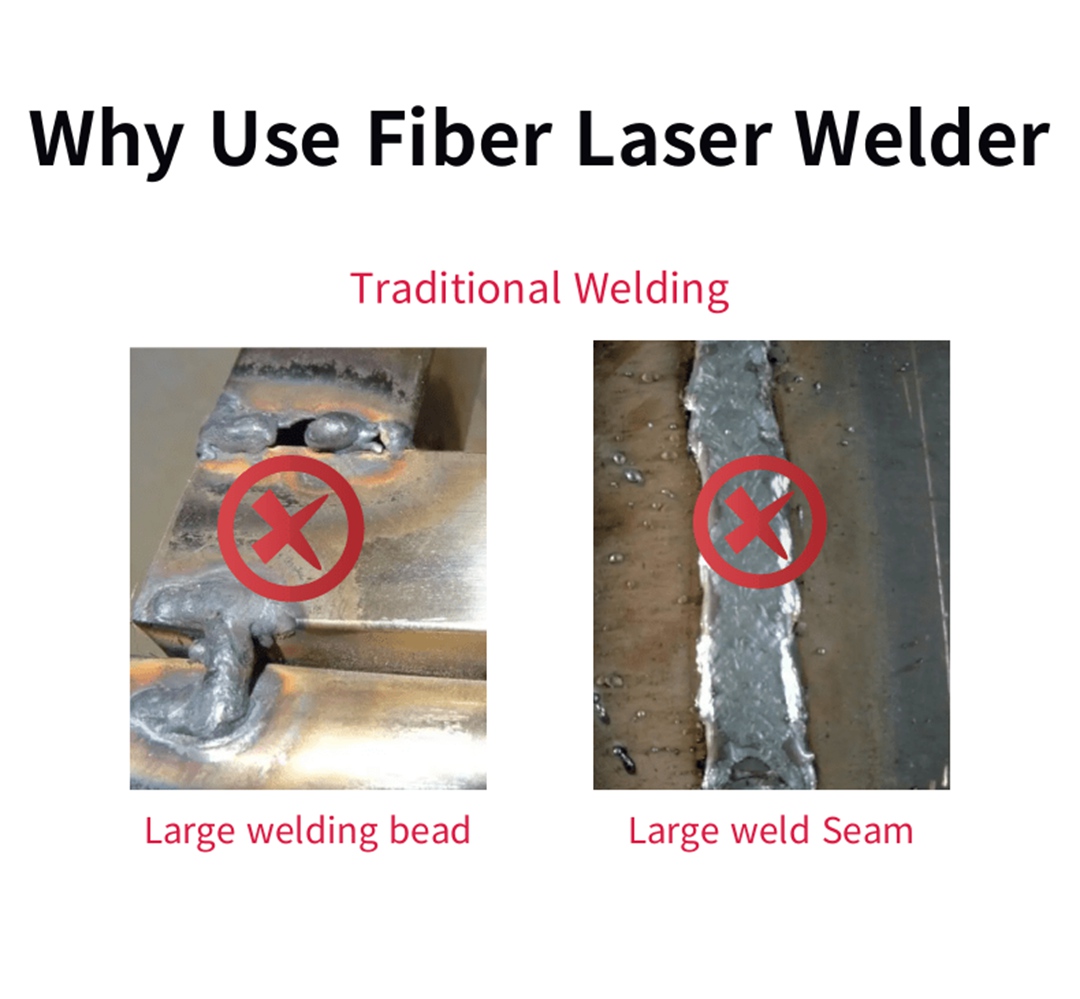

Laser welding is to irradiate a high-energy-density laser beam on two parts of a material, melt the material, and then cool and solidify into one. Compared with traditional welding techniques, automatic wire-feeding hand-held laser welding has the following advantages:

1. The welding seam is flat and beautiful, and the work board without grinding or grinding is very small.

2. By controlling the laser energy, the welding will not deform or deform very little.

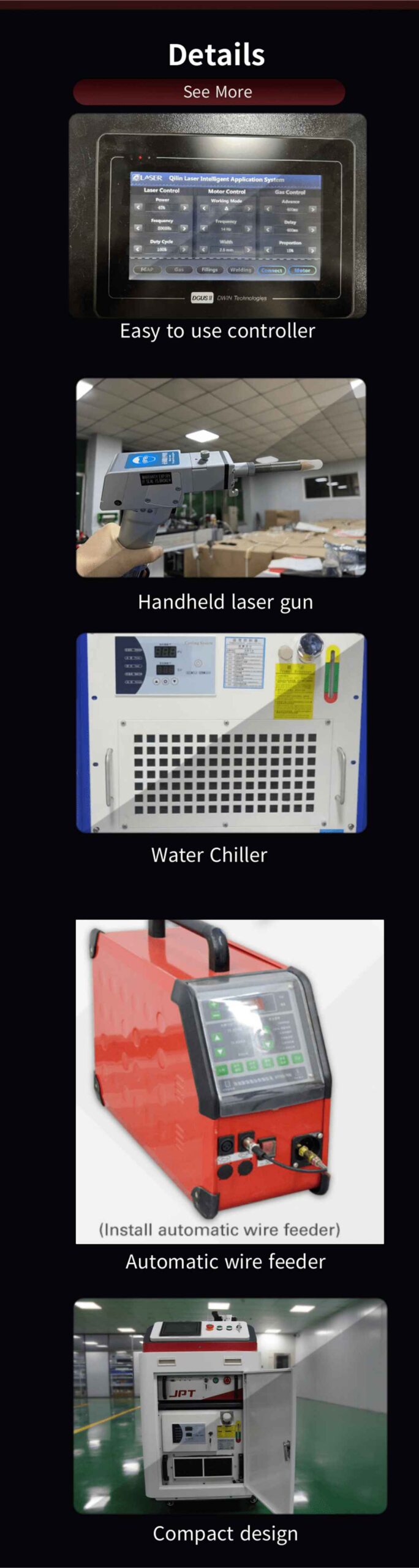

3. The hand-held laser welding machine is easy to operate and does not require a professional welder.

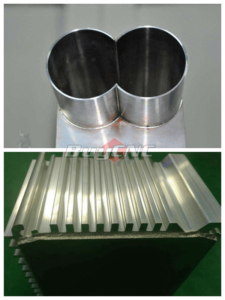

4. The swing welding machine can easily handle hard welding materials such as aluminum and brass.

5. The lifespan is up to 100,000 hours, and the consumption is low.

6. The automatic wire feeding handheld welding machine can weld parts with large gaps.

7. 8-15m fiber optic cable, which can weld long-distance and large-area parts.

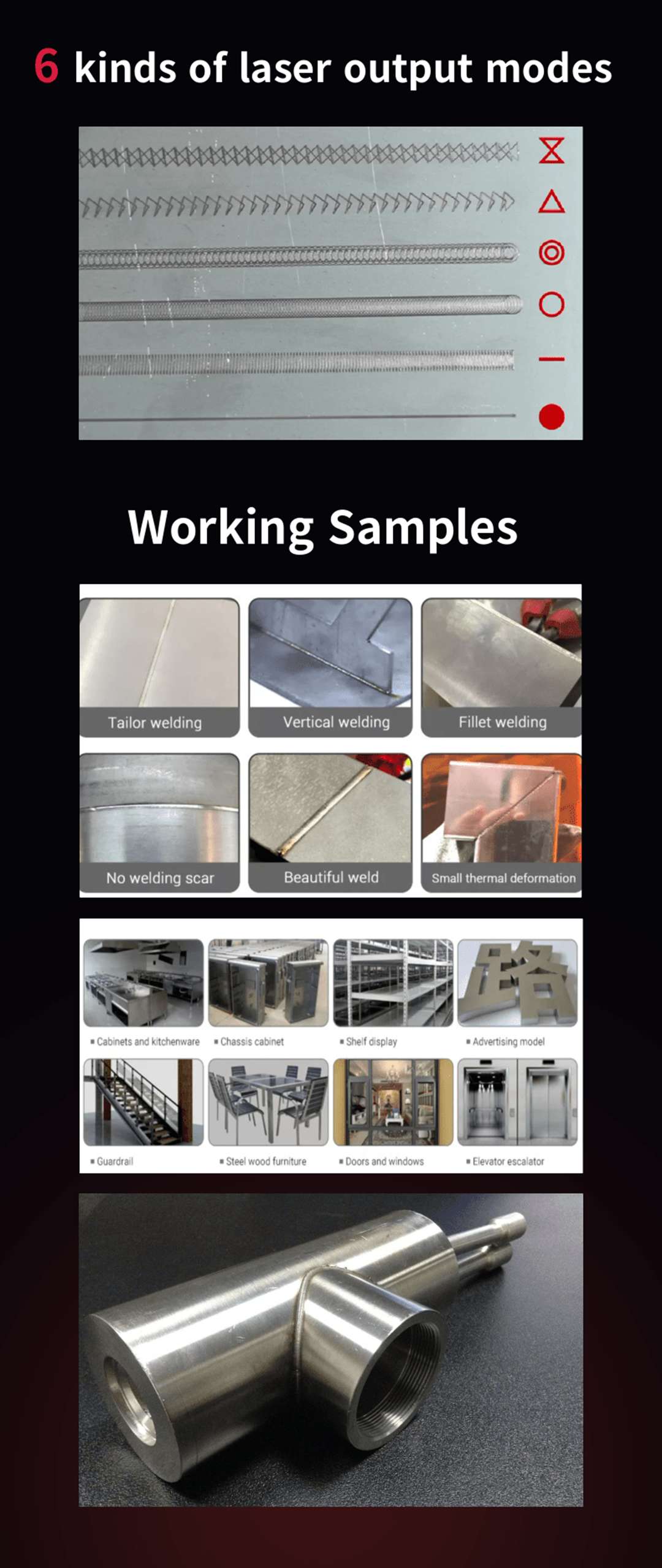

8. Various welding processes such as spot welding, seam welding and lap welding.

9. The welding efficiency is about 5 times that of TIG welding.

10. Used for welding in electronics, sheet metal, air conditioning and other industries.

The lazer welder is a laser welding equipment that couples a high-energy laser beam into an optical fiber, transmits it over a long distance, and collimates the parallel light through a collimator to weld the workpiece. And the handheld lazer welder adopts a new welding method, which is mainly used for welding precision parts of thin-walled materials. With less pollution and less consumption, this fiber lazer welding machine is a good choice.

The laser welding system adopts a new welding method, which is mainly used for the welding of thin-walled precision parts. The machine can also be used for plug welding, sealing welding, spot welding and stitch welding. The machine has the advantages of short welding seam length, high width ratio, imperceptible heat affected zone, small deformation, fast welding speed, beautiful welding seam, less post-weld repair work, high welding seam quality, and precise welding seam control. Accurate positioning, small spot focus, automatic welding. A laser welding system works by using a high-octane laser pulse to heat a tiny area of a specific area on the workpiece material. The powerful energy of the laser radiation is diffused into the material by thermal conduction,

The lazer welder uses high-energy laser pulses to heat a small area of material. The energy of the laser radiation is diffused inside the material by heat transfer, causing the material to melt to form a specific molten pool.

The fiber lazer welding machine is a new type of welding method, mainly used for the welding of thin-walled materials and precision parts.

The lazer welder can realize spot welding, butt welding, stitch welding, sealing welding, etc., with high aspect ratio, small weld width, small heat affected zone, small deformation, fast welding speed, smooth and beautiful weld, no need for processing or simple welding Post-processing, high welding seam quality, no pores, precise control, small focusing spot, high positioning accuracy, and easy to automate. This handheld lazer welder can meet almost all welding needs.

Advantages of Lazer Welder:

1. The beam will not shift

The laser in the handheld lazer welder passes through the electromagnetic field, and the beam will not be deflected; the laser can be welded in vacuum, air and a certain gas environment, and can be welded through glass or materials that are transparent to the beam.

2.The deformation of the welded workpiece is extremely small

The deformation of the fiber lazer welding machine welded workpiece is extremely small, there is almost no connection gap, and the welding depth ratio is high. which not only improves the appearance of the workpiece surface, but also reduces the amount of sheet metal used. Since the welding parts of the parts are almost not deformed, post-weld heat treatment is not required, and the rigidity of the body is also improved.

3. The beam can be split by time and space

The lazer welder can realize beam splitting according to time and space, and can perform multi-beam simultaneous processing and multi-station processing, which provides conditions for more precise welding.

4.flexible welding

The handheld lazer welder can weld hard-to-reach positions, non-contact long-distance welding, with great flexibility, no damage to the product surface, no scratches, and a small welding area.

Applications of Lazer Welder:

The handheld lazer welder mainly targets the fixed positions of large and medium-sized sheet metal, cabinets, chassis, aluminum alloy door and window frames, stainless steel wash basins and other large workpieces such as inner right angles, outer right angles, and flat welds. Handheld laser welding machine has a small heat-affected area, small deformation, And the welding depth is large and the welding is firm. The lazer welder is widely used in kitchen and bathroom industry, home appliance industry, advertising industry, mold industry, stainless steel product industry, stainless steel engineering industry, door and window industry, handicraft industry, household products industry, furniture industry, auto parts industry, etc.

our service:

pre-sale service

1. 24-hour quick pre-sale response and free consultation;

2. Provide users with any form of technical support;

3. Provide free sample making;

4. Provide free sample testing;

5. Provide advanced solution design for all dealers and users.

After-sales service

1. 7x24hours quick feedback;

2. Provide “training video”, “instruction manual” and “operation manual”;

3. Provide a simple troubleshooting manual for the machine;

4. Rich online technical support;

5. Provide quick spare parts and technical support;

6. Provide free training services.

Related articles

Advantages Of Laser Welder for Aluminum in Various Applications

Table

Future Of Laser Steel Welding Machine and Laser Welder Aluminum

Table

Want to Get the Lazer Welder Price?Get Free Consultation Now!!!

Reviews

There are no reviews yet.