Fiber Laser Cutting Machine Parameters

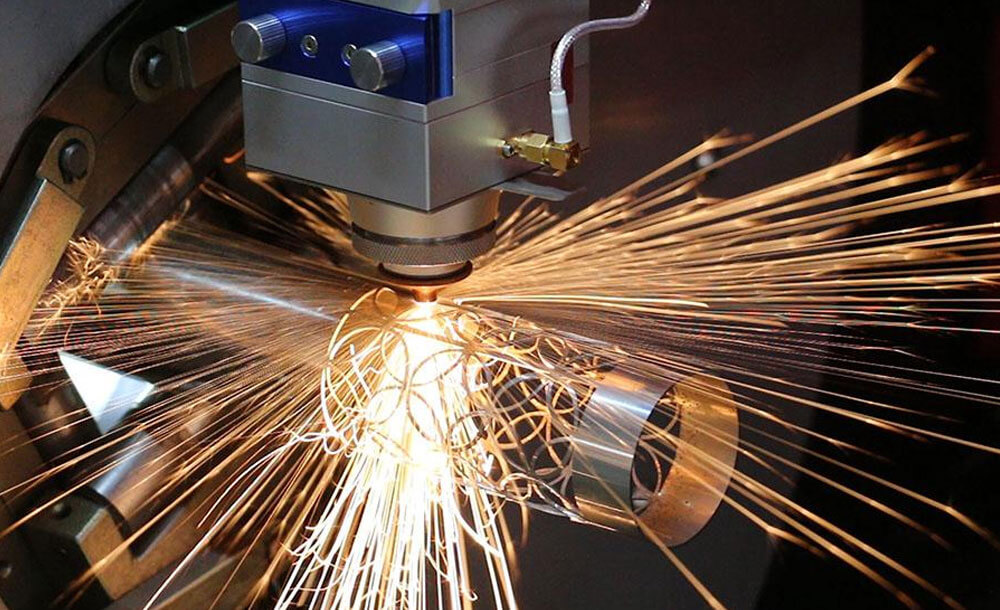

Whenever I do after-sales service to a customer who has purchased a fiber laser cutting machine, most people will ask me the same question. That is, “how do you see the fiber laser cutting machine parameters?”. Indeed, the fiber laser cutting machine’s parameter setting is essential, which directly affects the quality of material cutting. So, how to set the fiber laser cutting machine parameters? What kind of parameter settings can speed up the cutting speed while improving the material’s cutting quality? And what is the cutting speed of different power fiber laser cutting machines for products of different materials? This article will take these questions and explain them to you one by one. I hope you have a good reference when purchasing a fiber laser cutting machine.

This article roughly divides the cutting quality of fiber laser cutting machine parameters into four parts. They are the influence of auxiliary air pressure, laser power, cutting speed, and focus position.

1.Auxiliary air pressure is one of the parameters that affect cutting quality.

We all know that in the process of fiber laser cutting machine processing, the role of auxiliary gas is to blow off the slag produced by cutting and cool the heat-affected zone of cutting. We usually include oxygen, compressed air, nitrogen, and inert gases as auxiliary gases for fiber laser cutting machines. For some metallic and non-metallic materials, inert gas or compressed air is the most suitable. Because such auxiliary gas can prevent the material from burning, the inert gas is used to cut aluminum alloy material. For most metal materials, active gas (such as oxygen) is used because oxygen oxidizes the metal surface to improve cutting efficiency.

Here we want to remind everyone that the auxiliary pressure generated is not easy to be too high or too low. Because when the auxiliary air pressure is too high, eddy currents may appear on the surface of the cut material, which weakens the ability to remove the melt, and the final material cut will not only widen, but the cut surface will be very rough. When the auxiliary air pressure is too low, the molten material cannot be completely blown away, which causes the slag to adhere to the lower surface of the material. Therefore, in processing with a fiber laser cutting machine, the auxiliary gas pressure must be adjusted reasonably to achieve perfect cutting quality.

2.Laser power is one of the parameters that affect cutting quality.

BuyCNC provides you with 500w, 1000w, 1500w, 2000w, 3000w, 4000w fiber laser cutting machines. A variety of fiber laser cutting machines are sufficient to meet your needs. The fiber laser cutting machine’s power affects the cutting speed, slit width, and cutting thickness and ultimately directly affects the cutting quality of the material. When purchasing a fiber laser cutting machine, customers must consider the cutting material’s characteristics and the principle of the cutting equipment.

For example, for materials with good thermal conductivity, high melting point, and high reflectivity of the cutting surface, a larger power fiber laser cutting machine needs to be purchased. After years of practice, the mechanical engineers of BuyCNC believe that the fiber laser cutting machine must have a laser power that can obtain the best cutting quality under certain other conditions. If the cutting power is higher or lower in the actual cutting process than such an optimal power, the cutting quality will be significantly reduced.

Therefore, in the third part of this article, we aim at the 1000w and 1500w fiber laser cutting machines that are most demanded by customers. We have listed the 1000w and 1500w fiber laser cutting speed chart for different materials for your reference.

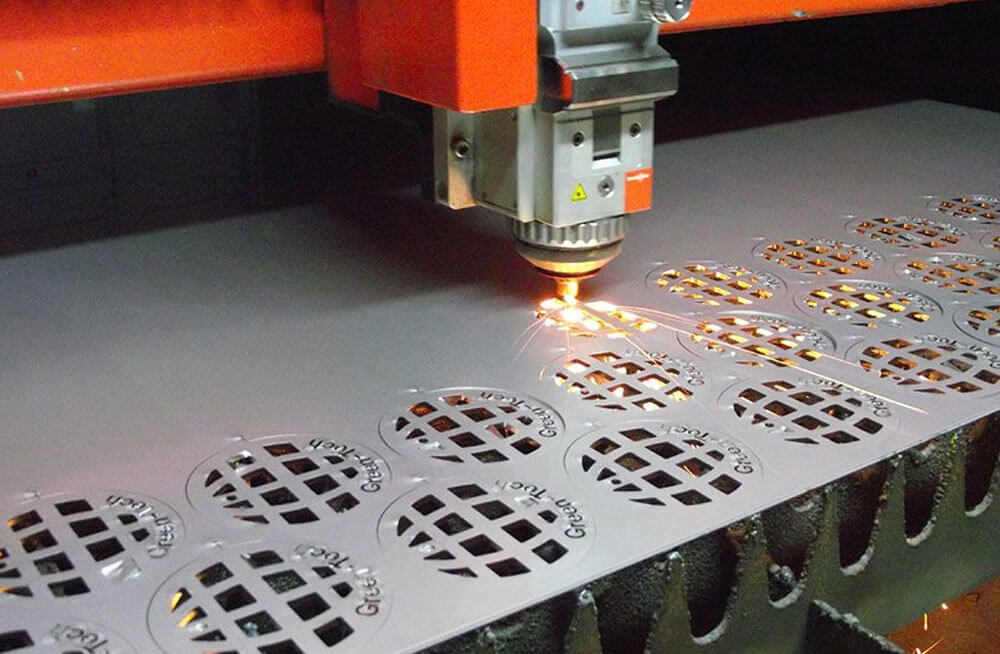

3.Cutting speed is one of the parameters that affect cutting quality.

In fiber laser cutting machine processing, the cutting speed has a considerable influence on the cutting quality. Proper cutting speed will make the cutting surface show a relatively stable line and will not produce slag in the lower part of the material. When the auxiliary gas pressure and laser power are constant, the cutting speed and the slit width are inversely proportional.

In other words, when the cutting speed is relatively slow, the action time of the laser energy on the slit will be prolonged, increasing the width of the slit. When the speed is too slow, the laser beam’s action time is too long, resulting in a large difference between the upper and lower slits of the materials, thereby reducing the cutting quality. As the cutting speed increases, the laser beam energy’s action time on the materials becomes shorter, which reduces the thermal diffusion and heat conduction effects, thereby reducing the width of the slit. When the cutting speed is too high, the material will not cut through due to insufficient cutting heat, which is called incomplete cutting. Besides, the molten material cannot be blown off in time, and the molten material may cause the cut seam to be re-welded.

The following is the 1000w fiber laser cutting speed chart and the 1500w fiber laser cutting speed chart. The fiber laser cutting speed chart clarifies the cutting speed for different cutting materials and the matters needing attention in the cutting process.

| 1000W Fiber Laser Cutting Speed Chart for Cutting Stainless Steel, Carbon Steel, Brass, Aluminum Single-module RFL-C1000 core 25μm cutting data (collimation 100mm, focus 125mm) | |||||||

| Material | Thickness (mm) | Speed (m/min) | Power (W) | Gas | Pressure (bar) | Nozzle (mm) | Cutting height(mm) |

| CS | 1 | 18 | 1000 | N₂ | 10 | 1.5S | 0.6 |

| 3 | 3 | O₂ | 0.6 | 1.0D | 1 | ||

| 6 | 1.5 | 0.6 | 1.5D | 1 | |||

| 8 | 1.1 | 0.6 | 1.5D | 1 | |||

| 10 | 0.8 | 0.6 | 2.5D | 1 | |||

| SS | 1 | 20 | 1000 | N₂ | 12 | 1.5S | 0.6 |

| 6 | 14 | 2.0S | |||||

| 3 | 3 | 16 | 3.0S | ||||

| 4 | 1 | 16 | 3.0S | ||||

| 5 | 6 | 18 | 3.5S | 0.5 | |||

| Aluminum | 1 | 18-20 | 1000 | N₂ | 12 | 1.5S | 0.6 |

| 2 | 5 | 14 | 2.0S | ||||

| 3 | 1.5 | 16 | 3.0S | ||||

| Brass | 1 | 12 | 1000 | N₂ | 12 | 2.0S | 0.6 |

| 2 | 2 | 14 | 2.0S | ||||

| 3 | 0.8 | 16 | 3.0S | ||||

| Note: The red-marked parameters in the figure are proofing parameters. They are greatly affected by various factors in actual processing. They are only suitable for small batch production. Actual high-volume production processing is not recommended. Higher-power lasers are recommended. | |||||||

| 1500W Fiber Laser Cutting Speed Chart for Cutting Stainless Steel, Carbon Steel, Brass, Aluminum Single-module RFL-C1500S core data 50μm cutting data (collimation 100mm, focus 125mm) | |||||||

| RFL-C1500S Continuous Laser (50μm) | |||||||

| Material | Thickness (mm) | Speed (m/min) | Power (W) | Gas | Pressure (bar) | Nozzle (mm) | Cutting height(mm) |

| Carbon steel | 1 | 22 | 1500 | N₂ | 12 | 1.5S | 0.5 |

| 3 | 3.6 | O₂ | 0.6 | 1.0D | 1 | ||

| 6 | 14 | 0.6 | 1.5D | 1 | |||

| 8 | 1.2 | 0.6 | 1.5D | 1 | |||

| 10 | 1 | 0.6 | 2.0D | 1 | |||

| 12 | 0.8 | 0.6 | 2.5D | 1 | |||

| 14 | 0.65 | 0.6 | 3.0D | 1 | |||

| 16 | 0.5 | 0.6 | 3.0D | 1 | |||

| Stainless steel | 1 | 25 | 1500 | N₂ | 12 | 1.5S | 0.5 |

| 2 | 8 | 14 | 2.0S | 0.5 | |||

| 3 | 4.5 | 16 | 2.5S | 0.5 | |||

| 4.5 | 1.5 | 18 | 3.0S | 0.5 | |||

| 5.5 | 0.8 | 18 | 3.0S | 0.5 | |||

| Aluminum | 1 | 18 | 1500 | N₂ | 12 | 1.5S | 0.5 |

| 2 | 6 | 14 | 2.0S | 0.5 | |||

| 3 | 2.5 | 15 | 2.5S | 0.5 | |||

| 4 | 0.8 | 17 | 3.0S | 0.5 | |||

| Brass | 1 | 15 | 1500 | N₂ | 14 | 1.5S | 0.5 |

| 2 | 5 | 16 | 2.0S | 0.5 | |||

| 3 | 1.8 | 18 | 3.0S | 0.5 | |||

| 4 | 1 | 20 | 3.5S | 0.5 | |||

| Note: The red-marked parameters in the figure are proofing parameters. They are greatly affected by various factors in actual processing. They are only suitable for small batch production. Actual mass production processing is not recommended. Higher power lasers are recommended. | |||||||

If you need to know the 500w fiber laser cutting speed chart, 2000w fiber laser cutting speed chart, 3000w fiber laser cutting speed chart, and other problems to be solved, please contact us now.

4.Focus position is one of the parameters that affect cutting quality.

The focal position refers to the distance from the focal point of the fiber laser to the material’s surface. The roughness of the cut surface, the slope, width of the slit, and the molten residue’s adhesion are greatly affected by the focal position. If the focus position is too far forward, the cut material’s lower end will absorb more heat. Under the condition of constant cutting speed and auxiliary gas, the cutting material will melt into liquid and flow on the lower surface.

Then, the melted material will adhere to the lower surface of the material in a spherical shape after cooling, which affects the cut surface’s roughness. If the focus position is too far back, the lower end of the material being cut will absorb less heat. In this way, the material in the slit cannot be completely melted, and some sharp and short residues will adhere to the lower surface of the board.

Therefore, in using a fiber laser cutting machine, we should pay attention to the influence of auxiliary air pressure, laser power, cutting speed, and focus position on cutting quality. In actual manufacturing, it is necessary to find the power and speed of a fiber laser cutting machine suitable for cutting materials. If you are using a fiber laser cutting machine, the cutting quality is not very good. Please feel free to consult us for help. BuyCNC will provide you with free services around the clock.