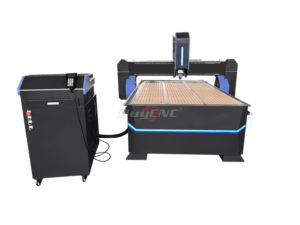

Best CNC Wood Cutting Machine for Sale

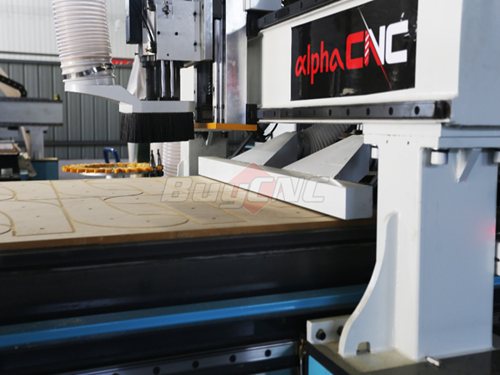

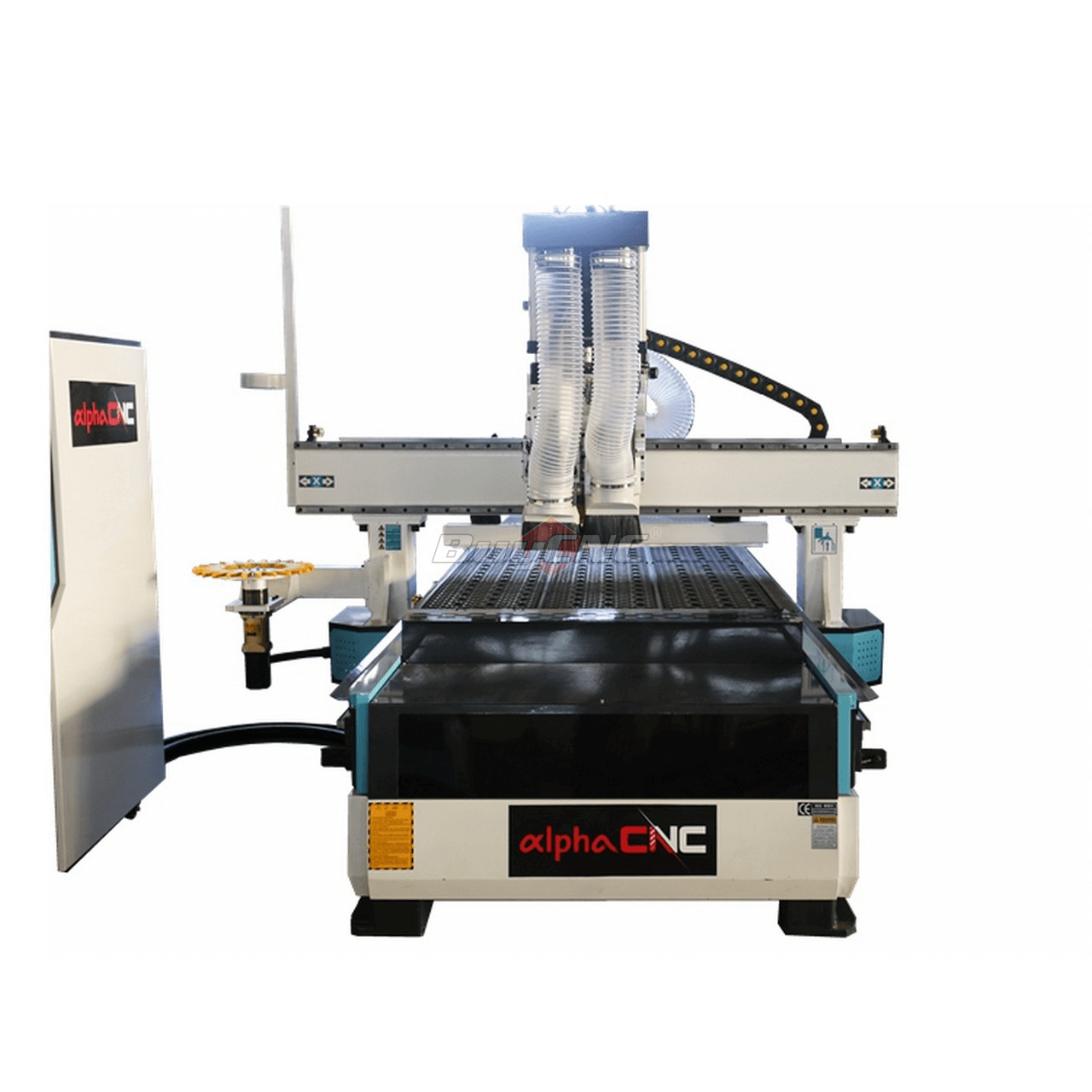

Are you looking for the most suitable CNC wood Cutting machine? Please come and take a look at Buycnc’s latest CNC wood Cutting machine, it may be your best choice for CNC woodworking. This CNC Cabinets machine is all heavy steel construction providing the rigid foundation required for ultra-smooth routing results. This CNC wood Cutting machine has two spindles, a 9KW (12HP) automatic tool changer with an 8-16 position rotary carousel, which can provide you with the best chip removal function during the CNC woodworking process. You can use it to process wood, Particleboard, plywood, plastic, soft metal, and other materials. If you need to buy a CNC wood cutting machine now or have questions about the CNC Cabinets machine. You can contact us immediately, we will reply you in time.

CNC woodworking machine Video

Feature of Cheap CNC Cabinets Machine

Stronger,Stable and Durable Structural Design of CNC Wood Cutting Machine

A very strong and stable structure is very important for CNC Wood Cutting Machine. The gantry of Our cabinet door making equipment is made of tubular steel, and the entire length of the column is welded with reinforcing ribs to achieve a stable beam Components. High-quality engineering and craftsmanship can achieve smooth precision cutting.

Easy to Operate and High Work Efficiency of CNC router cabinets

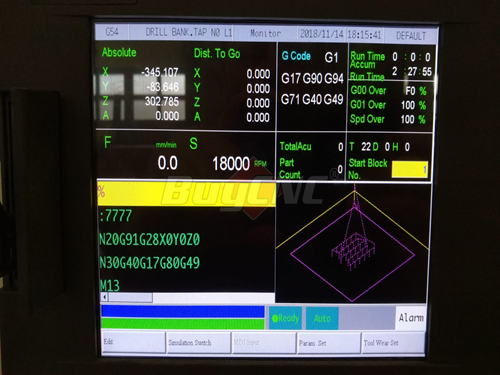

The CNC cabinet router machine is very easy to learn and use,because it adopts the Industrial Syntec FC Controller.This controller has higher reliability, higher precision, and stronger anti-interference ability.The CNC woodworking machine adopts Taiwan Hiwin or PMI square rail, which is more than twice durable. And the machine use of high quality helical rack pinion,which make the CNC Cabinets machine has high Efficiency and precision.

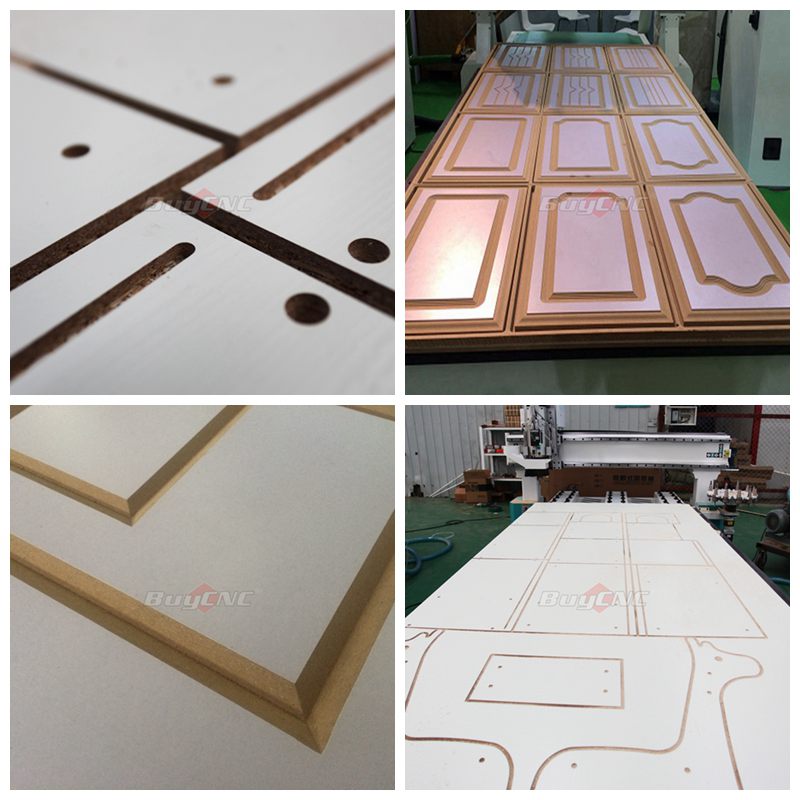

High quality CNC woodworking Process of CNC Cabinets Machine

The CNC wood cutting machine comes standard with 9kw high-frequency automatic tool change spindle. This precision spindle requires no maintenance and uses industry-standard ER chucks and ISO 30 tool holders. The speed can be controlled by programming, the speed range is from 6000 to 24000 RPM, and it is equipped with a pneumatic telescopic vacuum cover. This makes this CNC cabinet very precise deep cutting of wood and powerful dust removal function. So that wood for cabinet making can get better quality after CNC woodworking.

Application in Industries for CNC Woodworking Machine

| CNC Wood Cutting Machine Application Industry | Cabinet Industry | |

| Furniture Industry | ||

| Decoration Industry | ||

| Musical Instrument Industry | ||

| Gift Customization Industry | ||

| Art Model Industry | ||

| Other | ||

| Material that can be cut by CNC Wood Cutting Machine | Wood | MDF |

| Plywood | Soft metal | |

| OBS | Particle Board | |

| Acrylic | Other | |

CNC Cabinets Wordworking Machine Technical Parameters

| Description | CNC Cabinets CNC Wood Cutting Machine Parameters |

| Model | AIS-1325-D-ZK |

| Working Size | 1300*2500*200mm (4*8ft) |

| Accuracy | ±0.01/2000mm |

| CNC Router Table Surface | Double layer Vacuum |

| Frame | Thicken steel Square Heavy structure |

| X, Y Structure | X Y axis helical rack and pinion transmission |

| Z Structure | Taiwan TBI Ball Screw |

| Max. Rapid Travel Rate | 60m/min |

| Max. Working Speed | 40m/min |

| Spindle Power | 9kw(12HP) HQD ATC air cooling spindle ISO 32 |

| Spindle Speed | 0-24,000RPM |

| Collet | ER25 |

| Drive Motors | Stepper motor and driver |

| Working Voltage | AC380V/3PH/50Hz |

| Command Language | G Code |

| Operating System | Taiwan Syntec |

| Software capabilities | Vectric Aspire/AlphaCAM /Cabinet Version |

| Running Environment | Temperature: 0℃~45℃ Relative Humidity: 30%~75% |

Main Parts of Cheap CNC Wood Cutting Machine

Robust gantry of cabinet making machinery for sale

The gantry of The CNC Cabinets CNC Woodworking Machine is made of welded thick steel pipes, and reinforcement ribs are welded to each column of the gantry. In this way, Our CNC cabinets making machines not only ensure the stability of the gantry, but also can load a variety of driver components, such as belts, and wiring harnesses, motors, bearings, etc.

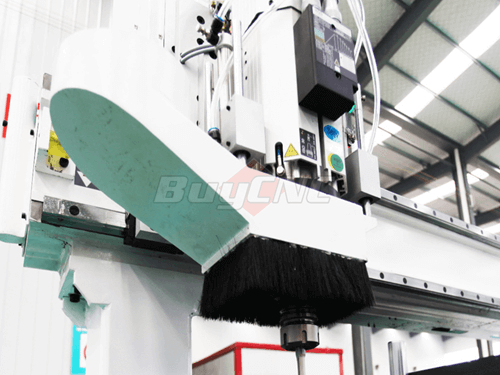

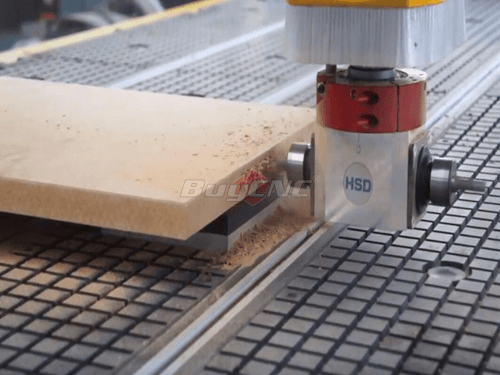

9KW High Frequency Automatic Tool Changer Spindle

The spindle used by Our CNC Wood Cutting Machine is 9KW High-Frequency Automatic Tool Changer Spindle, As an industry-leading CNC cabinet component, this spindle uses the industry-standard ER chuck and ISO 30 tool holder, and also comes with a pneumatic telescopic vacuum cover. While ensuring the quality, this precision spindle basically does not require much maintenance. We can adjust the speed of this CNC router for CNC cabinet making through programming. It can meet all operations during CNC woodworking.

Italy FAM Drilling Head of CNC Wood Cutting Machine

The CNC wood Cutting machine adopts the most popular FAM boring head is a 5+4 vertical model. The boring heads for CNC cabinets machines are available in a wide range of models with vertical spindles, horizontal spindles, or cutting units. The independent spindle boring heads are equipped with a series of remote-controlled solenoid valves with just one connection, eliminating the need to wire each individual spindle.FAM use of pneumatically driven units with oval section pistons guarantees a 35% increase in thrust in the spindle lowering mechanism, compared to traditional units with a circular section.

Syntec Controller of CNC Woodworking Machine

In order to ensure the stability during CNC woodworking, the control system used by our CNC wood Cutting machine is Syntec FC Controller. This control system has higher reliability, higher precision, and stronger anti-interference ability. There is a pulse loss phenomenon. And it can transmit more information. If you want to upgrade and program the Syntec FC Controller of CNC Cabinets Machine, you don’t need additional operations, just do it directly.

Drive Train Assembly of CNC Wood Cutting Machine

The CNC Wood Cutting Machine uses precision helical gear racks on the X-axis and Y-axis. In order to achieve a better CNC woodworking process, our unique Drive Train installation method prevents dust and debris from accumulating on the drive system. , And also ensure smooth movement and long-term reliability. The precision gearbox is directly coupled to the Servo motor and pinion. This eliminates belt stretch in accuracies assuring high-speed machining while the system positions the spindle accurately.

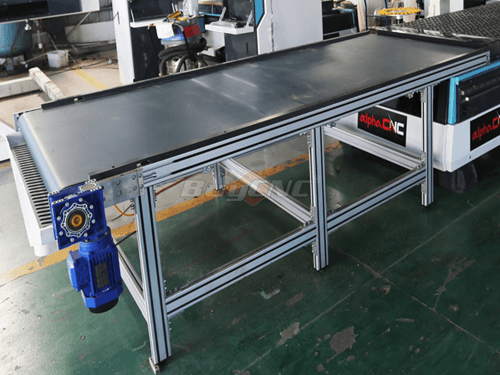

Finished material pushing system&Vacuum brush

The CNC Wood Cutting Machine Come with the vacuum brush and finished product pushing system. This Finished material pushing system can push the cut product to the front of the machine table, and at the same time, the vacuum brush behind the beam will suck away the small wood chips remaining on the table, which makes the CNC Cabinets Machine able to absorb the material more vacuum, Which also improves the quality of our CNC woodworking.

Hiwin or PMI square rail

Rotary Vane Vacuum Pump

Pneumatic Material Alignment Stops

CNC machine Holder Clamp

CNC Tool Rotary Carousel magazine

CNC Tool Calibration

Optional Parts of Cheap CNC Woodworking Machine Kit

Automatic loading&Unloading system

HSD Aggregate Tool

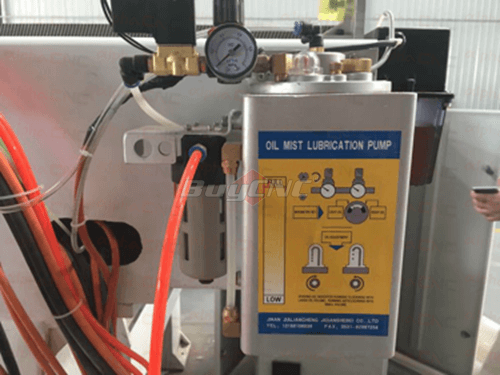

Oil mist Coolant System

Projects of CNC Cabinets Making Machine

Strong Factory Strength of CNC Woodworking Machine

BuyCNC is with advanced and powerful machining capability. We have high precision 5 axis CNC Machining center to process the CNC cabinets machine frame. The top milling, side milling, and side drilling will be finished in the same machining center by one clamping, which ensure our CNC machines are with higher precision. Not only the machine frames but also the small machining parts are machined by ATC CNC Center too.

High Precision Installation for CNC Wood Cutting Machine

During the installation of key components such as guide rails and racks, a dial indicator is used to check the installation accuracy to ensure the high precision of the CNC woodworking router cheap machine.

Our Service

Packing for Affordable CNC Woodworking Machine

- Step 1: PVC film packing, which can ensure that the CNC woodworking machine is completely covered, avoiding water and rust.

- Step 2: Wooden box packing, with a fixed template on the outermost layer.

- Step 3: All of the packing are inspected carefully by QC before delivery.

Pro-Sale Service of Cheap CNC Woodworking Machine

- Free sample testing service: you can send us the CAD file of the sample you want to cut, we will cut it at the factory and send the cutting video to you, or we can mail the sample to you.

- Personalized customized solutions: In order to meet your needs of cutting quality and efficiency, we can design unique solutions according to your requirements.

- Inquiries and consulting services for all CNC woodworking machine.

After-Sale Service of Cheap CNC Cabinets Machine

- The warranty period is 2 years for the best CNC woodworking machine.

- When you need to replace the wearing parts of cheap CNC cabinets machine, we will provide them at the agent price.

- If there are any problems during the warranty period, we will replace the main parts free of charge.

- The CNC wood cutting machine for sale software provides free lifetime update service.

- 24-hour online technical support (phone, email, Teamviewer, Whatsapp, Skype, WeChat, QQ, etc.)

- We provide English training videos and user manuals for 4×8 CNC woodworking router machine sale installation and operation, etc. We can also provide technical guidance remotely.

- Free training at the BuyCNC factory.

- The engineer can repair the 4×8 plywood CNC router overseas.

Delivery for Cheap CNC Woodworking Machine for sale

All of the cheap CNC router can be shipped worldwide. You can choose shipping by sea, by train, by truck, by air or by international express and DHL, FEDEX, UPS, etc. Click the button below to submit your information, we will provide you with professional service. Welcome!

Related articles

Woodworking CNC Machine Operation is Simple and Intuitive

Table

About BuyCNC

BuyCNC is a leading High-quality CNC Machine supplier in China. BuyCNC develops and sells various CNC machines including CNC Routers, Laser Machines, and Plasma Cutting Machines. Our main products are wood CNC router, stone CNC router, metal CNC router, ATC CNC router, 4 Axis CNC router, 5 Axis CNC router, CO2 laser engraving cutting machine, fiber laser cutting machine, fiber laser marking machine, fiber laser welding machine, and metal plasma cutting machine etc.

The production complies with European standards and international quality control and has FDA, CE, SGS, and ISO9001 certification. The factory produces more than 1,000+ machines annually. And BuyCNC has Rich R & D’s experience which has been focusing on researching, developing, and manufacturing CNC machines for more than 20 years. Serving more than 150 countries and regions, we have 10000+ customers all over the world.

You can get the cheap CNC woodworking machine directly without any CNC router distributor. Don’t hesitate anymore, tell us your needs to buy an cheap CNC router from BuyCNC.

Working Hours

Monday- Thursday:8:00-18:30 Hrs

Phone&Whatsapp&Wechat: +86 186 1540 9281

Website: www.buycnc.com

We Are Here

Dinghao Square, Xiaxia District, Jinan, Shandong Province, China

Want to Get the Latest CNC Wood Cutting Machine Price?Get Free Consultation Now!!!

Reviews

There are no reviews yet.