Table of Contents

What is the Fiber Laser Welding Machine

The laser welding machine is also known as fiber laser welding machine, pulse laser welding machine, YAG laser welding machine, etc. With the continuous development of science and technology, traditional welding methods can no longer meet the requirements of industry for welding, laser welding aluminum The combination strength of the machine is relatively low, and the advantages of heat-affected area are also relatively wide, especially in many industries, which have replaced traditional industries.

The welding galvanized steel machine mainly uses high-energy laser pulses to locally heat a small area of the material. The energy of the laser radiation diffuses into the material through heat conduction, thereby melting the material into a specific molten pool. Laser welding also has a new type of The main welding method is the welding of thin-walled materials and precision parts, which can realize spot welding, butt welding, stitch welding, sealing welding, etc., with high aspect ratio, small weld width, small heat-affected zone, and small deformation. The welding speed is fast, the welding seam is smooth and beautiful, there is no need to handle or only simple treatment after welding, the welding seam quality is high, it can be accurately controlled, the positioning accuracy is high, and it is easy to realize automation.

Application Industries of Fiber Laser Welding Machine

The fiber laser welding machine is a kind of machine used in the welding field. It is one of the important aspects of the application of laser material processing technology. According to its working mode, it can be divided into laser molds and welding machines, automatic laser welding machines, and laser points. Welding machine, fiber laser welding machine, etc., in which industries can laser welding aluminum machine be used? Here is an introduction to the 5 major application industries of laser welding machine.

Manufacturing applications

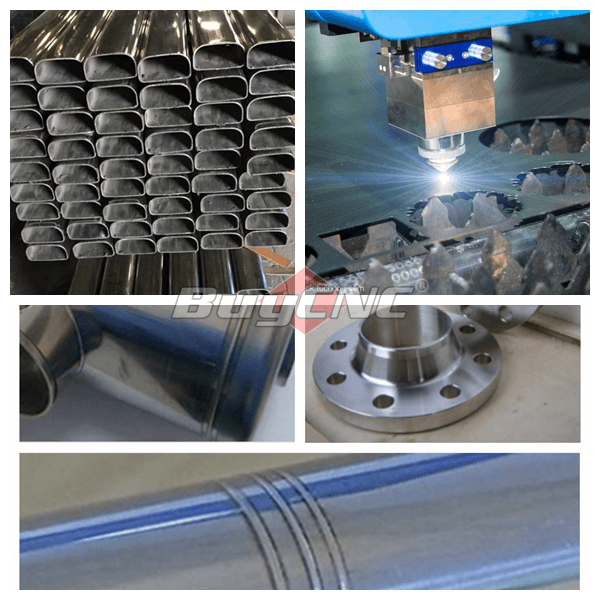

The laser welding aluminum machine is widely used in automobile manufacturing at home and abroad. In Japan, CO2 laser welding machine used to replace flash butt welding for the connection of rolled steel coils in the steel industry. In the research of ultra-thin plate welding, such as foils with a thickness of less than 100 microns, there is no way to weld them, but through YAG laser welding with a special output power waveform was successful, showing the broad prospects of laser welding.

Powder metallurgy field

With the continuous development of science and technology, many industrial technologies have special requirements for materials, and materials manufactured by traditional technologies can no longer meet the requirements. The welding galvanized steel machine enters the field of powder metallurgy material processing, bringing new development prospects for the application of powder metallurgy materials. For example, the brazing method commonly used in powder metallurgy material connection is used to weld diamond, because the bonding strength is low and the heat affected zone is wide. In particular, it is unable to adapt to high temperature and high strength requirements, causing the solder to melt and fall off. The use of laser welding aluminum machine can improve the welding strength and high temperature resistance.

Electronics industry

The laser welding aluminum machine has been widely used in the electronics industry. Because laser welding has a small heat-affected zone, rapid heating concentration and low thermal stress, it has shown unique advantages in the packaging of integrated circuits and semiconductor device shells. In the development of vacuum devices, laser welding aluminum machine has also been applied . The thickness of the elastic thin-walled corrugated sheet in the sensor or temperature controller is 0.05-0.1mm, which is difficult to solve by traditional welding methods. TIG welding is easy to weld through, the plasma stability is not good, and there are many influencing factors. The laser welding effect is very good. It is widely used.

Auto industry

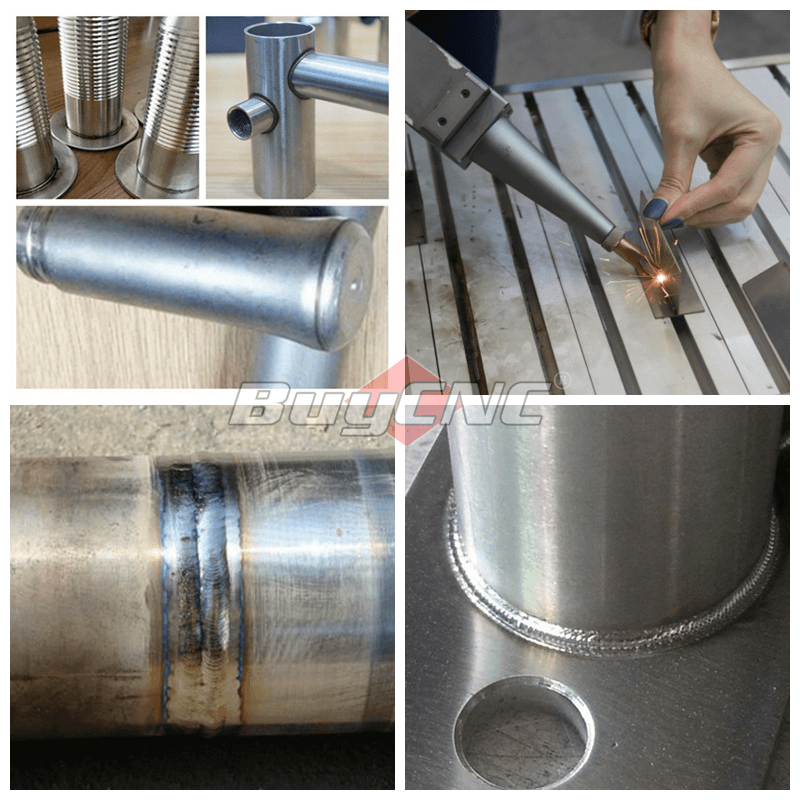

The laser welding aluminum machine is widely used in the automotive industry: engine cylinder gaskets, hydraulic tappet sealing welding, spark plug welding, filter welding, etc. Medical industry: welding of medical appliances, stainless steel seals for medical appliances, and structural parts. Sealing and breaking welding of solid state relays, welding of connectors and connectors, welding of metal shells and structural parts such as mobile phones and MP3s. Welding of motor shell and connection, optical fiber connector joint, etc. Household hardware, kitchenware and bathroom, stainless steel door handles, electronic components, sensors, clocks and watches, precision machinery, communications, handicrafts and other industries, automotive hydraulic tappets and other industries with higher strength products.

Bath industry

The laser welding aluminum machine is widely used in the sanitary ware industry: welding of water pipe joints, reducing joints, tees, valves, and showers. Glasses industry: precision welding of the buckle and outer frame of the glasses made of stainless steel, titanium alloy and other materials. Hardware industry: welding of impellers, kettles, handles, etc., complex stamping parts and casting parts.

These industries mentioned above almost all use laser welding aluminum machines. The advantages of welding galvanized steel machine are energy concentration, no pollution, small solder joints, a wide range of weldable materials, high applicability, and high efficiency and high-speed welding. So the fiber laser welding machine is more and more popular in many industries.

What Materials Can the Laser Welding Machine Process

Fiber laser welding machine is a kind of welding equipment commonly used in the welding industry. This type of laser welding aluminum machine has many advantages and is widely used. However, many people do not know which materials are welded by laser welding. Now,BuyCNC will ask you to teach!

The laser welding aluminum machine can weld the following materials:

1. Stainless steel

In general, stainless steel welding is easier to get a good discussion than conventional welding. Because the heat-affected zone of the high welding rate is small, sensitization does not become a stressful result. Compared with carbon steel, the low thermal conductivity of stainless steel makes it easier to obtain deep penetration narrow welds.

2. Die steel

The laser welding aluminum machine can be used for welding S136, SKD-11, NAK80, 8407, 718, 738, H13, P20, W302, 2344, and other materials, and the effect is good.

3. Carbon steel and popular alloy steel

Carbon steel adopts a laser welding machine to stop welding, the effect is superior, and its welding quality depends on the impurity content. In order to obtain satisfactory welding quality, preheat when the carbon content exceeds 0.25%. When steels with different carbon content are welded to each other, the welding torch can be slightly directed to the side of the low-carbon material.

In addition to the above materials, the laser welding aluminum machine can also weld several products or materials with certain processing requirements.

1. Products with requirements for welds

Laser welding aluminum machine is generally used in product industries that require welding seams. This kind of industry hopes that the weld seam is as small as possible, so using a fiber laser welding machine to process materials is the best method.

2. Products with high automation

In this case, the fiber laser welding machine can be manually programmed for welding, and the path is automatic.

3. Products at room temperature or under special conditions

This fiber laser welding machine can perform welding at room temperature or under special conditions, and the installation of this fiber laser welding machine is simple. For example, when the laser passes through an electromagnetic field, the beam will not shift; the laser can be welded in a vacuum, air, and certain gas environments, and can be welded through glass or materials that are transparent to the beam.

4. Fiber laser welding machine is needed for some inaccessible parts

It can weld hard-to-access parts, and implement non-contact long-distance welding, which has great sensitivity. Especially in recent years, the use of optical fiber transmission technology in YAG laser processing technology has made laser welding technology more popular.

All the above these materials can be welded with a welding galvanized steel machine, and the welding galvanized steel machine can weld far more than the above materials. It can be said that there are many materials welded by laser welding machines. We believe that welding galvanized steel machines will develop better and better in the future development path, and be able to play their role in more and more industries.

Laser Steel Welding Machine For Sale