Table of Contents

What is a mold laser welding machine

Mold laser welding machine is a machine that uses conventional laser welding methods to achieve local heating of small areas by laser welding machine, laser spot welding, laser repair and other methods to achieve the purpose of melting and combining materials, also known as mold. Laser repair machine.

The mold laser welding machine was first called the laser welding machine. During the development process, the mold laser welding machine was also called the mold laser repairing machine, but they all used the conventional laser welding method to realize the laser welding machine and laser spot welding. , laser repair and other methods for local heating of small areas to achieve the purpose of melting the material.

The mold laser welding machine is also a branch of the laser welding machine, so the working principle is to use high-energy laser pulses to locally heat the material in a small area. The energy of the laser radiation diffuses into the material through heat conduction, and the material is melted and formed. specific melt pool.

It is a new type of welding method, mainly for the welding of thin-walled materials and precision parts, and can realize spot welding, butt welding, stitch welding, sealing welding, etc. The deformation is small, the welding speed is fast, and the welding seam is smooth and beautiful.

No need or simple treatment after welding, high welding seam quality, no porosity, precise control, small focusing spot, high positioning accuracy, and easy automation. At present, high-power laser welding machines have been launched, and various styles of laser welding machines and repairs can be realized for thicker materials.

Advantages of Mold Laser Welding Machine

1. The mold laser welding machine adopts a large-screen LCD screen, which makes it easier for the operator to learn and operate; the equipment can also realize multi-mode work and is suitable for most mold repairs.

2. The heat affected area is small, the oxidation rate is low, the mold repaired by welding has no deformation, and the repair effect is good.

3. Laser welding can realize a variety of welding methods: spot welding, butt welding, stitch welding, sealing welding, etc.

4. The laser power is large and the welding speed is fast.

5. Ergonomic design, easy to operate.

6. The laser waveform can be adjusted, and the parameters can be set according to different welding materials to achieve better welding effect.

Mold Laser Repair Welding

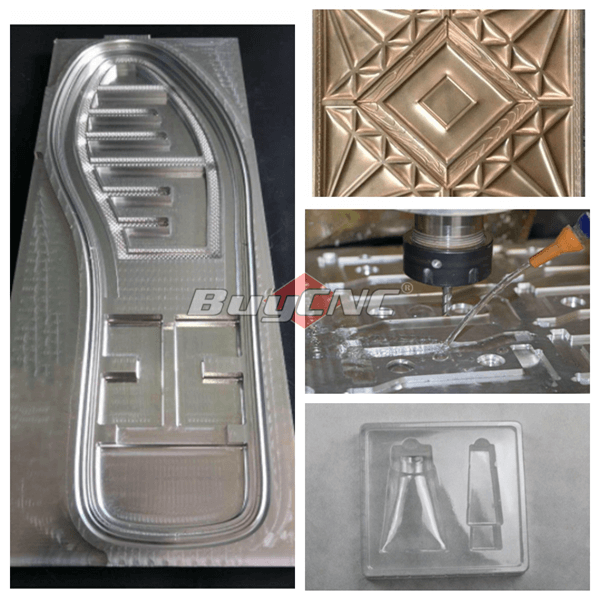

Mold plays an extremely important role in modern industry, and its quality directly determines the quality of the product. As the use time becomes longer, the mold with the best quality will appear collapse, deformation, wear and so on. When the mold is damaged, the most cost-effective for the business is of course to have a professional mold repairer repair it. How to repair the mold? In general. Repairing molds can be divided into traditional methods and the latest laser mold repair welding methods. Today, BuyCNC mainly talks about mold laser repair welding.

Now the mold laser welding machine technology is more and more mature. Most materials used to make molds contain large amounts of carbon and alloys. It is difficult to weld these materials by traditional welding methods, while laser welding can control the light output by adjusting parameters to achieve the optimal welding effect.

Laser die welding machine is a precision welding process with laser as heat source. There are many advantages to repairing molds with laser welding, including: 1. Low heat output, low heat output means that most laser mold repairs can be performed without preheating. ; 2. The heat affected zone is small, the workpiece will not be deformed, and it can be welded for small gaps; 3. The stress can be eliminated by the controllable pulse shape, thereby producing a crack-free weld. 4. High-precision welding that minimizes additional post-repair stages such as regrinding. In short, the laser mold repair welding machine is superior to the traditional welding mold repair process.

In addition, using a laser mold repair welding machine can reduce post-processing requirements, shorten mold repair time, improve mold quality, and extend mold life. Moreover, it only takes very little time (a day or so) for the operator to learn to laser weld mold repair!

Laser Welding Machine For Sale