Guide of 4 Axis CNC Router Machine

The 4 axis CNC machine has a very comprehensive function, which can realize engraving, cutting, punching, plane engraving, 3D engraving and so on. And can process stone, wood, metal, plastic and other materials. Now more and more customers choose 4 axis CNC wood router machine to engage in a variety of industries. If you want to process 2D workpieces as well as 3D workpieces, then the 4 axis CNC machine will be your best Options.

What is the 4 axis CNC router machine

The 4 axis CNC wood router machine refers to a CNC machine tool with four working paths of X, Y, Z and A axes. Since the spindle of the 4 axis CNC router machine can swing from side to side, the spindle can be moved from multiple different angles. Approach the workpiece and effectively process three effective machining surfaces. This CNC machine tool can realize not only plane engraving, but also 3D engraving of irregular workpieces. In four-axis machining, milling is performed on an additional axis. The 4-axis CNC milling machine kit runs on the X, Y, and Z axes like a 3-axis machine tool, but it also includes rotation around the X axis (called A axis). This is the fourth axis added to our workflow. A 4-axis CNC milling machine is also called a 4-axis CNC milling machine table, a 4-axis CNC machine tool, and a 4-axis CNC machining center. It can be processed by four-axis linkage, and it can process planes, reliefs, cylinders, non-standard three-dimensional patterns and corners of 3D patterns.

4 axis CNC milling machines can generally be divided into CNC milling machines and rotary axis CNC milling machines. Compared with a 3 axis CNC milling machine, the main shaft of the fourth-axis engraving machine can rotate 180 degrees left and right. This type of CNC milling machine can not only realize plane processing, but also can perform processing on both sides. It mainly performs some surface treatments on 3D workpieces.

Advantages of 4th Axis CNC Machine

The CNC4 axis machine is now favored by more and more customers, because the 4 axis CNC router machine can almost meet all the needs of CNC machine Industry. For example, cutting, carving, digging, fine carving, 3D carving, 2D carving and other processing methods. So do you know the advantages of CNC 4 axis router machine?

1. Higher production efficiency

The 4 axis milling machine has high production efficiency, can process workpieces efficiently, and can effectively reduce the interference caused by man-made in the processing process, so it can reduce production time and improve production efficiency .

2. Simplified work process

Because of the high degree of automation of the 4 axis milling machine, it can greatly simplify the processing of products by the workers, greatly save the workers’ time and energy, and simplify the processing process.

3. Higher cutting accuracy

The 4 axis milling machine is generally equipped with a high-power spindle. This spindle has high cutting accuracy and can engrave high-precision products. After the code is confirmed, the 4 axis CNC mill machine can produce in a short time Produce multiple products.

4. Processing is more flexible

4 axis milling machine involves the same process involved in 3-axis machining, where a cutting tool is used to remove material from the workpiece to produce the desired shape and contour. However, in four-axis machining, milling is performed on an additional axis. The 4-axis CNC milling machine kit runs on the X, Y, and Z axes like a 3-axis machine tool, but it also includes rotation around the X axis (called A axis). This is the fourth axis added to our workflow. So the 4 axis CNC router machine can process materials at multiple angles, making the machining process more flexible.

The 4 axis CNC router machine Industry

Furniture manufacturing industry

The woodworking machine tool industry has started from the popularization of numerical control technology, and has gradually developed in the direction of complete sets, high-end, and large-scale. On a four-axis machining equipment, a variety of operations can be completed, such as turning, milling, engraving, drilling, boring, reaming, sawing, grooving, grinding, etc., so this machine is very Popular in furniture making industry.

Musical instrument industry

The CNC wood router machine has now been widely used in the musical instrument industry. Because the cutting precision of the 4 axis router machine is very high, it can engrave exquisite musical instruments and can be mass-produced.

Advertising industry

Now more and more advertising signs have been carved by CNC machine. This machine can process a variety of materials to produce billboards. For example, wooden billboards, metal billboards, plastic billboards, etc.

Decoration industry

The 4 axis milling machine can process a variety of materials, such as stone, wood, metal, etc., through embossing, cutting, engraving, 3D engraving and other processing methods. The 4 axis CNC machine can engrave the material through the Z axis, which is very suitable for the production of customized decorative materials and large batches of decorative materials.

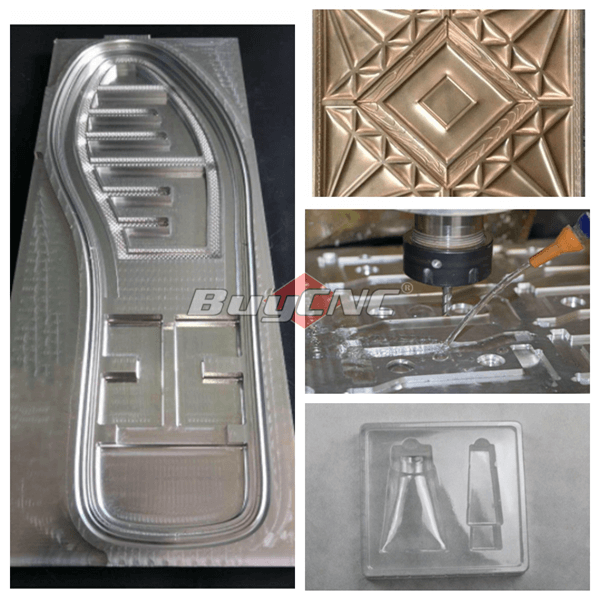

Mold manufacturing industry

The 4 axis router machine has also been widely used in the mold manufacturing industry now, because mold manufacturing requires extremely high-precision engraving, if manual engraving is used, it will cause mold defects, so more and more people choose to use CNC router machine To produce a variety of high-precision molds.

What is the 4 axis CNC machining

4 axis milling machining involves the same processes involved in 3 axis machining, where a cutting tool is used to remove material from a piece to create the desired shape and profile. However, in the case of 4 axis machining, milling is performed on an additional axis. A 4-axis CNC machine operates on the X,Y and Z axes like a 3 axis machine, but it also includes rotation around the X-axis, which is called the A-axis. This is the 4th axis that’s added to our machining process. In most cases, the workpiece will be rotated to allow for cutting to occur around the B-axis.4 axis milling machine is useful when holes and cut-outs need to be made in the side of a piece or around a cylinder. They can provide quick and efficient work based off computer numerical inputs for precise results.

Function of CNC Router 4th Axis

The 4th axis is also called the CNC indexing head of the CNC machine tool. It is a machine tool accessory that can clamp the workpiece on the chuck or between two centers, and make it rotate, index and position. The advantage of adding the 4th axis to the machine tool is that it can make the machining plane of the tool wider, and can reduce the repeated clamping of the workpiece, improve the overall machining accuracy of the workpiece, and help simplify the process and improve the production efficiency. Specifically, the 4th axis can complete tasks that a 3-axis CNC machine tool can’t do at one time. Multi-sided processing of products can be realized through rotation, which greatly improves processing efficiency, reduces the number of clamping times, and shortens production time.

1. The rotation angle can process multiple surfaces at the same time, which improves the overall processing accuracy of the workpiece, which is conducive to simplifying the process and improving the production efficiency.

2. The three axes are X, Y, Z three linear moving coordinates, and the fourth axis is usually a rotary axis, which will cause the angular offset between the tool and the workpiece, that is, the surface normal of the tool axis and the workpiece. The workpiece forms an angle. One can expand the processing range, and the other can improve the processing conditions.

BuyCNC 4 Axis CNC Router Machine

The 4 axis CNC wood router machine has many categories, and these CNC router 4 axis machines have powerful processing capabilities. However, the price of the 4 axis router machine varies greatly due to factors such as processing size and processing capacity. For example, the price of a small CNC router 4 axis machine is around US$3,000, while the price of a large 4 axis CNC machine is tens of thousands dollars.

Professional 4 Axis CNC Router Machine

The professional large-scale 4 axis CNC wood router machine has very powerful processing capabilities, can complete 2D engraving and 3D engraving, and the machine is also a ATC CNC router machine, which can greatly improve the production efficiency of the machine. This professional CNC router 4 axis machine comes standard with many advanced CNC machine parts.Such as the 8-position tool,9KW High Frequency Automatic Tool Changer Spindle, Servo Motor Driver etc.The big 4 axis CNC machine can process wood, foam, medium density fiberboard, HPL, particleboard, plywood, acrylic, plastic, soft metal and many other different materials.This machine is very suitable for large factories and professionals to produce large-scale furniture, decoration materials, cabinets, cabinet doors and other products

Desktop Hobby 4 Axis CNC Router Machine

In addition to the large 4 axis CNC wood router machine, there is also a small amateur desktop 4 axis CNC router machine. This 4 axis machine is suitable for small factories and hobbyists. This kind of machine has a small footprint and is easy to move. And can complete high-precision processing. The most important thing is that its price is very cheap, about 3,000 US dollars, which is an investment with a high rate of return.

BuyCNC has a full range of 4 axis router machine, whether it is a large 4 axis machine or a desktop 4 axis CNC machine. We can provide you with the CNC 4 axis router machine you want, and we can also customize it for you according to your requirements CNC 4 axis machine, if you want to know more about 4 axis router machine, please leave your contact information, we will provide you with the most comprehensive service and the best price.