Table of Contents

As an advanced surface treatment technology, laser rust removal machine has achieved remarkable application results in the field of rust removal in recent years. However, when faced with the rust removal requirements of different materials and thicknesses, can laser rust removal machines be competent? This article will explore this issue in depth.

How does the laser rust removal machine work?

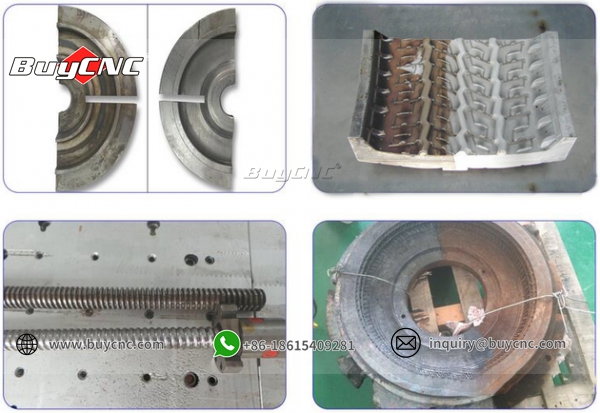

First, we need to understand how the laser rust remover works. The laser rust remover uses a high-energy laser beam to irradiate the surface of the object to be cleaned, and through the interaction between the laser and the material, the rust is quickly peeled off. This non-contact cleaning method not only avoids the damage that may be caused by traditional mechanical rust removal, but can also adapt to the rust removal needs of different materials and thicknesses to a certain extent.

Performance of laser rust removal machine during process

However, the performance of workpieces of different materials and thicknesses during laser rust removal is different. For metal materials, laser rust removal machines can usually achieve better results. The rust on the metal surface can be quickly peeled off under the irradiation of laser, revealing the original metallic luster. In addition, the laser rust removal machine can also adjust the laser parameters according to different metal materials to achieve the best rust removal effect. However, when faced with non-metallic materials or special alloys, the applicability of laser rust removal machines will be subject to certain limitations. These materials may have weak absorption capabilities for lasers, or their surface structures may be different from metals, resulting in poor laser rust removal. In addition, some special alloys may contain elements that are sensitive to lasers and are prone to thermal damage or deformation under laser irradiation.

Effect of workpiece thickness on laser rust removal machine

In addition to material factors, the thickness of the workpiece will also affect the applicability of the laser rust removal machine. For thinner workpieces, laser rust removers can usually handle it easily and quickly remove surface rust. However, for thicker workpieces, laser rust removal may take longer and may not be as effective as thin workpieces. This is because thicker rust layers may require higher laser energy and longer exposure times to be completely removed.

Laser rust removal machine manufacturers are constantly optimizing

In order to cope with the rust removal needs of different materials and thicknesses, laser rust removal machine manufacturers are also constantly innovating and optimizing technology. For example, by improving the design of the laser, the energy density and stability of the laser are increased; by developing an intelligent control system, automatic identification and adjustment of different materials and thicknesses are achieved; by combining other cleaning technologies, a multi-functional cleaning equipment is formed to adapt to Wider rust removal needs.

To sum up, the laser rust removal machine can be applied to the rust removal needs of different materials and thicknesses to a certain extent. However, in practical applications, it is necessary to select the appropriate laser rust removal machine model and parameters according to the specific material and thickness, and combine it with other cleaning technologies for comprehensive treatment. With the continuous advancement of technology and the expansion of application fields, it is believed that laser rust removal machines will provide more efficient and flexible rust removal solutions for more industries in the future.