Table of Contents

What is the laser welding machine?

Laser welding machine, also often called laser welding machine, laser welding cast steel machine, is a machine used for laser material processing. According to its working mode, it is divided into laser mold welding machine, automatic laser welding machine, laser spot welding machine, jewelry laser welder, optical fiber aluminum welder machine, optical welding is the use of high-energy laser pulses to locally heat the material in a small area. The energy of the laser radiation is diffused into the material through heat conduction, and the material is melted to form a specific molten pool to achieve the welding effect .

What are the types of laser welding machines?

In fact, there are many types of laser welding cast steel machines. Automatic laser welding cast steel machine and manual welding cast steel machine are two of them. Literally speaking, the difference between these two cheap aluminum welder machines is that one is automatic. , Another manual operation, so where is the specific difference? Now BuyCNC will explain to you what is the difference between automatic laser welding cast steel machine and manual laser welding cast steel machine?

What is an automatic laser cheap aluminum welder machine?

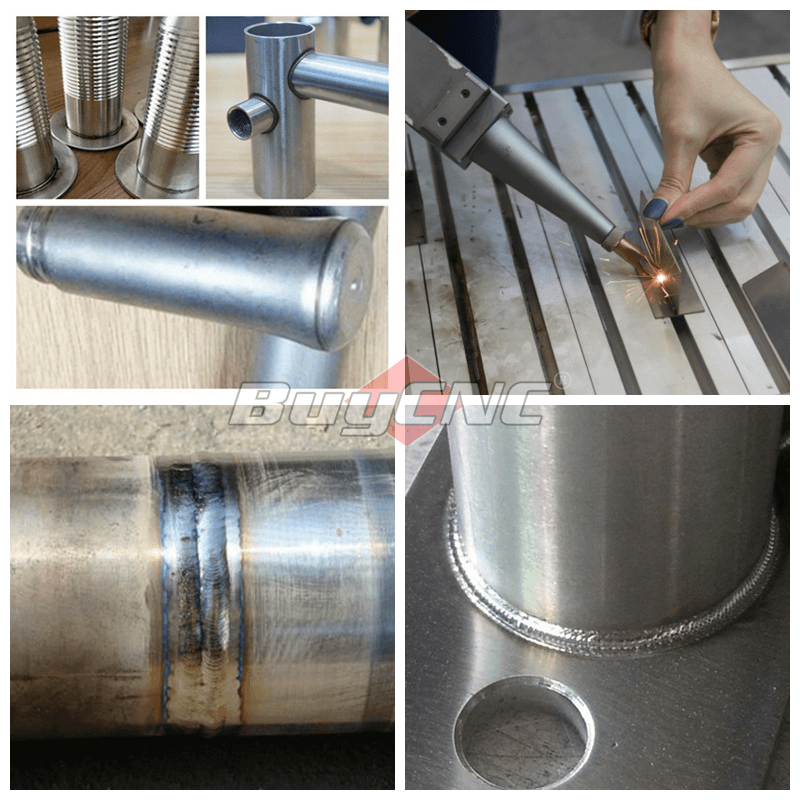

Automatic laser cheap aluminum welder machine is an automatic welding equipment that uses high-energy laser pulses to locally heat the material in a small area. The energy of the laser radiation diffuses into the material through heat conduction, and the material is melted to form a specific melt. Pool. Mainly for the welding of thin-walled materials and precision parts, it can realize spot welding, butt welding, stitch welding, sealed welding, etc., with small weld width, fast welding speed, high weld quality, no porosity, controllable, and high positioning accuracy , Easy to achieve automation and other features.

What is manual laser welding cast steel machine?

The manual laser welding cast steel machine, as the name implies, is a welding equipment that requires manual operation. This welding cast steel machine can perform laser welding of long-distance and large workpieces. The heat affected area during welding is small, and it will not cause deformation, blackening, and backside of the workpiece. There is a problem of traces, and the welding depth is large, the welding is firm, and the melting is sufficient. There is no depression in the joint between the convex part of the molten material in the molten pool and the base.

What is the difference between automatic laser welding cast steel machine and manual laser cheap aluminum welder machine?

Automatic laser aluminized steel welding machine is set on the software to automatically perform welding according to the set procedure; while manual aluminized steel welding machine is also called spot welding, which is manually made visible spot welding through high magnification on the screen.

What is the difference between automatic aluminized steel welding machine and manual laser aluminized steel welding machine? Just share it here. Many people may think that the automatic laser welding machine is automatic, so it is better, but in fact the purpose of these two equipment is different, and each has its own advantages, we need to choose according to actual needs in the process of selection To choose, choose the laser welding cast steel machine that suits your own production needs.

Several Popular Laser Welding Machines

Laser welding cast steel machine is now more and more widely used, especially in the entire electronics industry. It is slowly replacing the wave soldering used by current enterprises. It is a major industrial upgrading process. Its main advantages are: high efficiency, no consumables, and very Save electricity and labor.

According to the laser welding machines currently used on the market, they are mainly divided into the following types:

1. jewelry laser welder

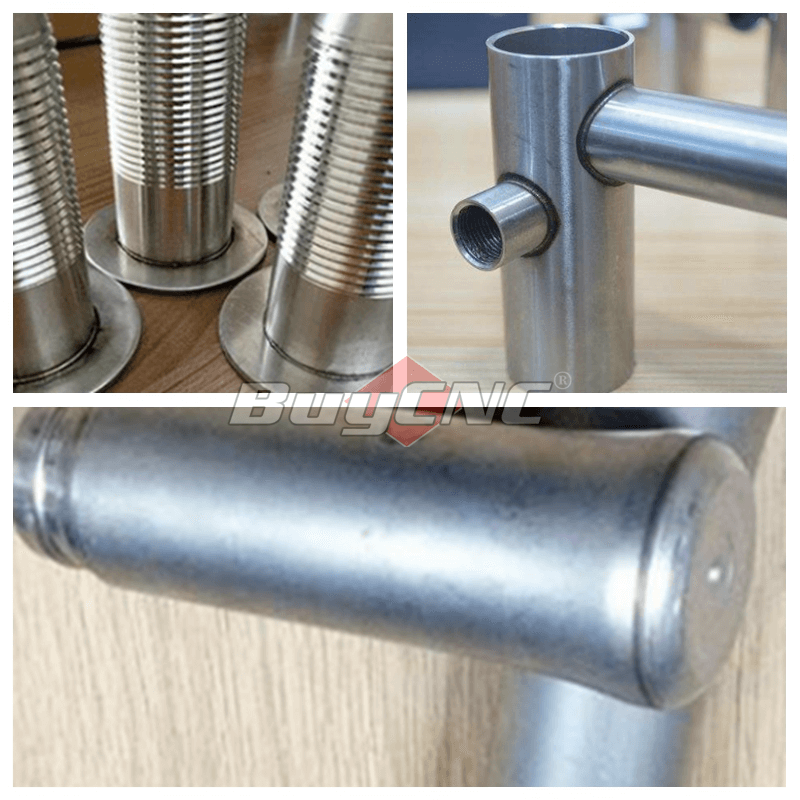

The jewelry laser welder is a laser spot welder designed mainly for irregular objects such as gold and silver jewelry and micro and small parts. This jewelry laser welder can weld extremely tiny things such as gold and silver jewelry.

2. Mold welding cast steel machine

Mold welding cast steel machine is mainly used for repairing and welding of die, precision injection molding, die-casting, stamping, stainless steel and other hard materials such as corners, cracks, gromming and depletion sealing edges; high accuracy rate, because the laser welding spot is finer, The heated area is small, so the processed parts are not easy to deform; the lines can be etched after welding, and the effect will not be affected.

3. Automatic laser welding cast steel machine

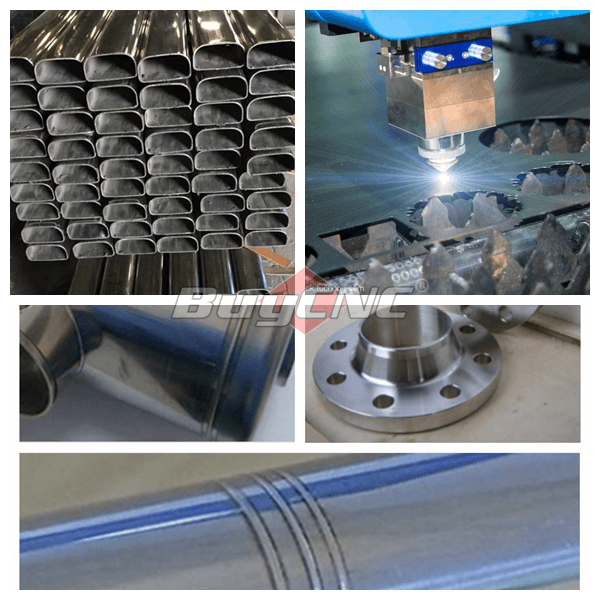

Automatic laser welding cast steel machine is developed on the basis of mold laser welding machine with high speed, high precision and automatic welding. A device suitable for continuous processing of some regular products. It is mainly used for laser welding of water pipe joints, tees, valves, showers, lithium batteries, battery packs, and electrodes. Welding of stainless steel, mobile phone screws, titanium alloys and other materials.

4. Galvo laser aluminized steel welding machine

Galvanometer laser aluminized steel welding machine is a high-speed welding machine developed on the basis of the above several welding machines to improve the production efficiency of enterprises. Compared with traditional automatic welding machines, galvanometer welding uses galvanometers to control the laser. Along the direction, a pattern such as a circle and a square is formed. So it is the laser that moves, not the workbench or fixture before. So it is faster and more accurate. Greatly save time cost and labor cost. Mainly used in: toys, mobile phones, electronic products, automobiles and other industries

5. Optical fiber transmission laser aluminized steel welding machine

Optical fiber transmission laser aluminized steel welding machine couples the energy laser beam, and then enters the optical fiber line, through the optical fiber line can achieve long-distance transmission, and then through the collimator to make it into parallel light, and then focus to make the laser into And a kind of laser welding equipment that implements welding on the workpiece with a thin point. Compared with the ordinary YAG welding machine, the beam quality of the laser spot after the laser is focused by coupling and other processes is smaller, the energy is stronger, the output is more stable, and the welding accuracy is higher. It is mainly suitable for the welding of buttons, battery tabs and other products and small materials that require high precision.

6. Fiber laser continuous welding machine

The fiber continuous welding machine is a machine that realizes welding through a continuous light emitted by a fiber laser. Like the fiber transmission laser welding machine, it also belongs to the YAG series, which only transmits through the optical fiber, and the fiber continuous welding is a real laser welding machine belonging to the optical fiber series. Therefore, its beam quality is better, and its continuous light is destined to be different. All of the above welding machines have pulsed light output modes. Only fiber laser continuous welding, and its light output mode is continuous. . Because of its continuity, it has stronger energy and greater heat, which can instantly melt the welding points of the product and realize welding. Mainly used in mobile phones, batteries, electronics, hardware, instruments, optical communications, aluminum and other industries.

The Main Welding Types of Cheap Aluminum Welder Machine:

1. Pulse laser welding: The pulse laser welding method of cheap aluminum welder machine is mainly used for the welding of single-point fixed continuous and thin materials, forming a round welding spot during welding.

2. Plasma arc welding: This cheap aluminum welder machine welding method is similar to argon arc, but its welding torch will generate a compressed arc to increase the arc temperature and energy density. It is faster than argon arc welding and has a greater penetration depth, but slightly Inferior to laser welding.

3. Continuous laser welding: This welding method is mainly used for welding and cutting large and thick parts, and a continuous weld is formed during the welding process. Generally speaking, the choice of welding materials, the choice of laser welding machine brand, and the choice of processing table are the main factors that affect the effect of laser welding.

4. Electron beam welding: It relies on a beam of accelerated high-energy density electrons to hit the workpiece, generating huge heat in a small dense area on the surface of the workpiece, forming a pinhole effect, and implementing deep penetration welding. The main disadvantage of electron beam welding is that it requires a high vacuum environment to prevent electron scattering. The equipment is complicated. The size and shape of the weldment are limited by the vacuum chamber. The assembly quality of the weldment is strict. Non-vacuum electron beam welding can also be implemented. Scattering and poor focusing affect the results.