Table of Contents

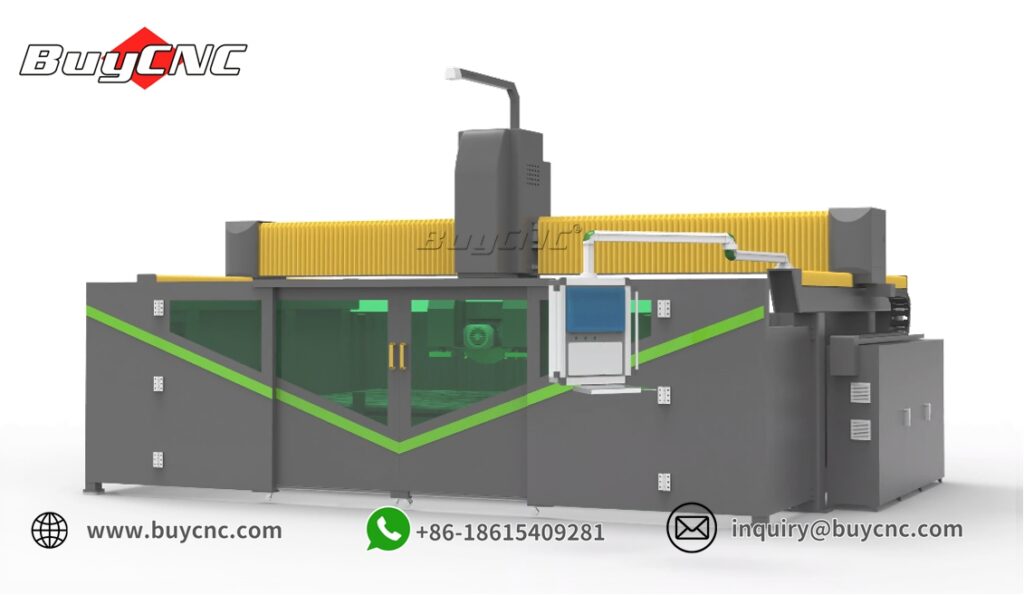

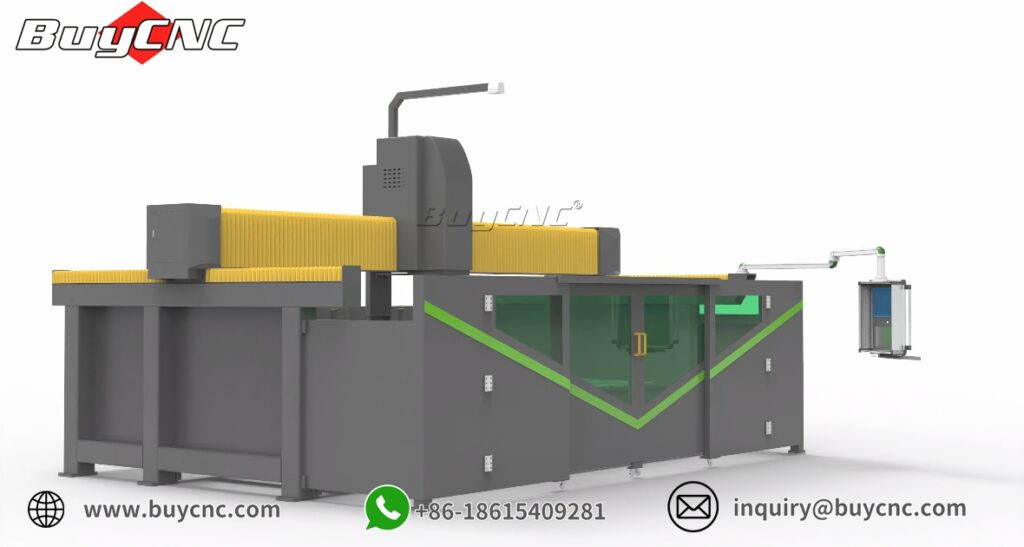

As an important piece of equipment in the stone processing industry, the stone carving machine‘s installation quality is directly related to the equipment’s operating efficiency and safety. Therefore, during the installation process, we need to pay special attention to some details to ensure that the stone carving machine can operate stably and efficiently and avoid potential problems.

Preparation work before installation of stone carving machine

Before installing the stone carving machine, we need to make sufficient preparations. First of all, read the installation instructions of the equipment carefully to understand the performance, structure, installation requirements and precautions of the equipment. Secondly, check whether all parts of the equipment are complete and whether they are damaged or missing. Finally, it is necessary to determine whether the installation site meets the requirements, including the bearing capacity, flatness, ventilation conditions, etc. of the ground.

Detailed control during stone carving machine installation process

The foundation of the stone carving machine is the key to supporting the entire equipment, and its installation quality directly affects the stability of the equipment. When installing the foundation, ensure that the size, location, levelness, etc. of the foundation meet the design requirements. At the same time, suitable concrete should be used for pouring and adequate curing should be carried out after pouring.

During the installation process of machinery, you need to pay attention to the following points:

(1) Installation of the spindle: The spindle is the core component of the stone carving machine, and its installation quality directly affects the processing accuracy and stability of the equipment. When installing the spindle, ensure that its verticality, coaxiality, etc. meet the design requirements.

(2) Installation of transmission components: Transmission components include motors, reducers, couplings, etc., and their installation quality directly affects the transmission efficiency and stability of the equipment. When installing transmission components, make sure their axes are parallel, their concentricity meets the requirements, and apply an appropriate amount of lubricating oil.

(3) Bearing installation: Bearings are key components that support rotating parts, and their installation quality directly affects the smooth operation and life of the equipment. When installing the bearing, make sure it is clean and free of rust, and apply an appropriate amount of lubricant to the surface of the mating part. At the same time, pay attention to the installation direction and position of the bearing to avoid installation tilt or misalignment.

(4) Installation of seals and pulleys: Seals and pulleys are important components to prevent equipment leakage and ensure transmission efficiency. When installing the seal, make sure it is pressed into the seal groove in parallel and cannot be twisted, deformed or damaged to scratch the sealing surface. When installing the pulleys, make sure that the axes of the two pulleys are parallel and the centers of the pulleys are facing each other to avoid excessive offset, which may lead to uneven belt tension and accelerated wear.

The electrical system is an important part of the stone carving machine, and its installation quality directly affects the operational stability and safety of the equipment. When installing the electrical system, ensure that the connections of each electrical component are firm and reliable, and wire them according to the electrical schematic diagram. At the same time, pay attention to the insulation performance and grounding protection of electrical components to avoid electrical failures and safety accidents.

Inspection and debugging after installation of stone carving machine

After the installation is completed, we need to conduct a comprehensive inspection and debugging of the stone carving machine. First, check whether the installation quality of each component meets the requirements and whether there is any looseness, misalignment, etc. Secondly, it is necessary to conduct no-load trial operation and load trial operation to check whether the equipment’s operation stability, processing accuracy and transmission efficiency meet the requirements. Finally, check whether the operation and safety performance of the electrical system meet the requirements.

Through the above detailed control and inspection and debugging work, we can effectively avoid potential problems during the installation process of the stone carving machine and ensure that the equipment can operate stably and efficiently. At the same time, we also need to pay attention to the daily maintenance and upkeep of the equipment, promptly discover and solve problems that occur during the operation of the equipment, and ensure the long-term stable operation of the equipment.