Table of Contents

CNC Router In Wood Cutting Industry

Now The CNC engraving router machine has been widely used in wood processing industry, whether it is wood cutting, wood engraving or wood drilling. So this CNC router cutting wood machine is very popular among furniture processing workers. The CNC plywood router not only optimizes the furniture manufacturing process, but also facilitates automatic feeding, processing, and discharging. It can also realize operations such as drilling at any angle, sawing at any angle, high-quality edge banding, and multi-workpiece processing. So now the CNC router plywood cutting machine has become the first choice for wood furniture processing. It can complete the processing of complex parts and quickly adapt to changes in design and technology. Together with the application of CNC technology, it can improve furniture production efficiency. Realize the rational use of resources.

With the continuous development of science and technology, the furniture manufacturing industry has ushered in tremendous changes. The low efficiency of using traditional woodworking methods to make panel furniture, the technical requirements for workers and the continuous increase in labor costs restrict the development of furniture factories. The resulting full-automatic CNC cutting machine for panel furniture has inevitably impacted the traditional woodworking masters. On the vent of the development of custom panel furniture, various furniture factories and decoration companies want to get a piece of cake in the custom furniture. . Now BuyCNC will introduce several CNC routers for wood cutting to you.

Several Popular CNC Cutting Wood Router

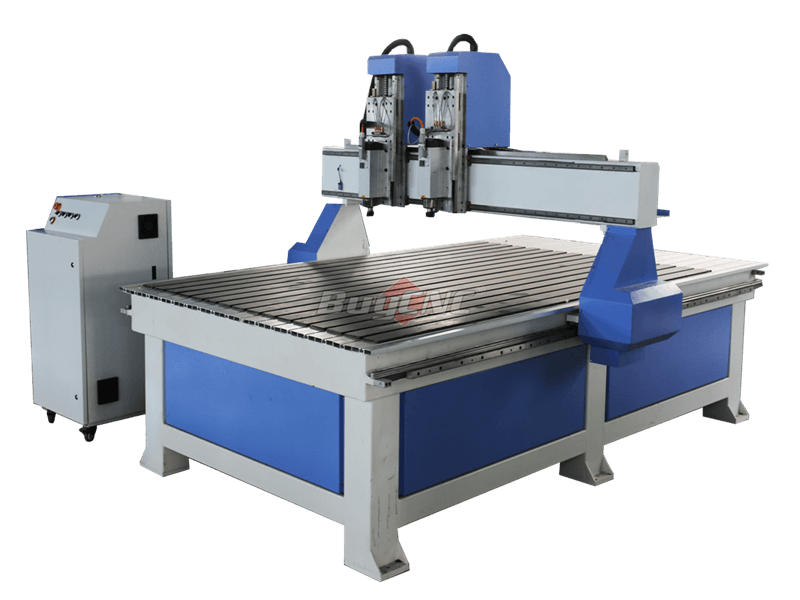

Dual-process CNC cutting router

This Double-process drilling wood cutting machine is mainly used for blanking of panel furniture production, it can complete vertical holes, slotting, cutting and other processes. It is the most efficient machine among all types of CNC cutting machines. The head part of this CNC wood router has two 6KW air-cooled main shafts with a 9 vertical row drill stand. The two spindles can hold milling cutters of different diameters, which are used for grooving, cutting, pneumatic switching, and the tool change efficiency is higher; the drilling package can hold 9 drills of different diameters, pneumatic switching, and the switching speed is fast. Moreover, as long as the adjacent holes are in suitable positions, multiple drill bits can be used to punch multiple holes at one time, which greatly improves the drilling efficiency and thus improves the overall processing efficiency.

Three-process CNC router cutting wood machine

The three-process CNC cutting machine is an economical CNC cutting equipment for customized furniture. The automatic tool change can be completed through program control, and the three working procedures can be continuously worked without stopping the tool change in the middle. The three spindles are installed side by side on the machine head, the tool change speed is faster, and the machining accuracy is high! Moreover, the functions of the three-process cutting machine are relatively comprehensive, which can be used for cutting panel furniture and milling cabinet doors. The CNC three processes are strictly produced in accordance with the bed structure and configuration of the heavy-duty machining center. The only difference from the machining center is the structure of the machine head. In terms of performance, it fully reaches the level of woodworking processing centers.

Four-process CNC router cutting wood machine

The four-process CNC router wood cut machine is an upgraded version of the three-process CNC wood router. Compared with the three-process CNC wood machine, an extra spindle motor is added. This machine has four main spindles, which can automatically switch the main spindle to punch, scribe, and cut the plate. The processing efficiency is three to four times higher than that of a single-head CNC cutting machine. The equipment can be equipped with an automatic loading and unloading device, eliminating the need for manual pick-up and higher efficiency. Normal production can process 40-50 sheets in 8 hours a day. This special model has become a popular model once it is launched. Generally, entrepreneurs who just want to set up factories will choose this CNC wood router cutting machine.

The Disc ATC CNC router wood machine

This machine is a disc tool change + drill row machining center machine.It is a multi-functional CNC router plywood cutter for custom furniture production. It is mainly used for milling and engraving of cabinet doors and wooden doors; it can also be used for vertical hole drilling, slotting and material cutting in the production of panel furniture. The spindle of the disc tool change + row drilling machining center is a high-power automatic tool change spindle, and is equipped with a large-capacity tool magazine, which can hold multiple tools of different purposes, and complete different processes through program control and automatic tool change. Compared with ordinary custom-made furniture equipment, it has great advantages!

CNC woodworking machining center

This professional CNC woodworking router machine is generally called a disc tool change machining center. It has a 9kw spindle and a tool magazine. The capacity of the tool magazine is generally 8-12 knives. Of course, 16 or 20 knives can be customized. No matter it is cutting, grooving, or punching, the tool can be changed automatically, which saves the trouble of manual tool changing. It is very suitable for gate-shaped processing.

For example, the cabinet door generally requires multiple forming knives of different shapes to complete the process. Generally, every time the equipment completes the process of a knife, it is necessary to stop the equipment to remove the knife on it, replace a knife, and re-align the knife. This is not only time-consuming, but also affects the processing efficiency. If the tool is not accurate, it will also affect the processing quality. Use the disc tool change + drilling machining center to make the cabinet door, and automatically change the tool to complete all the processes of the cabinet door processing at one time, eliminating the need for manual tool change, greatly improving the processing efficiency and product quality.So this machine is the most popular CNC router wood cutting machine in cabinet making industry.

Maintenance of CNC Router Wood Cutting Machine

1. The router wood cutting machine should ensure that the continuous operation time is 10 hours a day, the cooling water should be kept clean, and the water pump should be able to work normally. The water shaft motor must not have water shortage, and at the same time Pay attention to the regular replacement of the cooling water to avoid excessive water temperature. The temperature in winter is low, at this time we can replace the water in the tank with antifreeze.

2. After this CNC wood cutting machine is used every time, do not forget to clean it. There may be dust on the transmission system. Be sure to clean it up. The platform fluid should be kept clean at ordinary times. The vibration system should be lubricated regularly every week. . When lubricating and refueling, pay attention to that the xyz optical axis uses engine oil, and the screw part uses high-speed grease. In winter, the weather is cold and the temperature is too low. We can clean the lead screw and polished rod with gasoline first, and then refuel, otherwise the machine will be dislocated due to excessive resistance.

3. When doing maintenance and inspection for electrical parts, remember to cut off the power first, and wait until the monitor does not display and the indicator light of the main circuit power supply has gone out before proceeding.

Regarding how to maintain the wood cutting machine, the above is some relevant knowledge compiled by BuyCNC for everyone. Any machine should be maintained and maintained at the same time as it is used. This can increase work efficiency and extend the service life of the machine.

Summary

Through the above article, have you already had a preliminary understanding of several popular CNC wood router machines in the woodworking industry. The CNC wood cutting router machine is generally used in furniture factories for carving, embossing, cutting, hollowing, etc., which greatly exerts the artistic creativity of the furniture industry and can perfectly present furniture design and furniture manufacturing. It is a rare good tool. At present, some large furniture have dozens or even hundreds of woodworking engraving machines, and some small and medium-sized factories have also seen the business opportunities among them, and have purchased woodworking engraving machines. It can be imagined that woodworking engraving machines will become furniture in the near future. A mainstream member of machinery.

If you want to work in the furniture industry, a CNC wood router with excellent performance is an indispensable machine, it can create extremely lucrative profits for you. If you want to know The CNC router cutting machine price, please leave yours Contact information, we will recommend the most suitable machine for you.