Table of Contents

When purchasing an cnc wood carving machine, many users may overlook an important issue: whether installation, debugging and after-sales service are included. However, these issues are critical to ensuring the normal operation and long-term stability of the cnc wood carving machine. This article will discuss in detail the installation, commissioning and after-sales service you should enjoy after purchasing an cnc wood carving machine, and emphasize the importance of a one-stop solution.

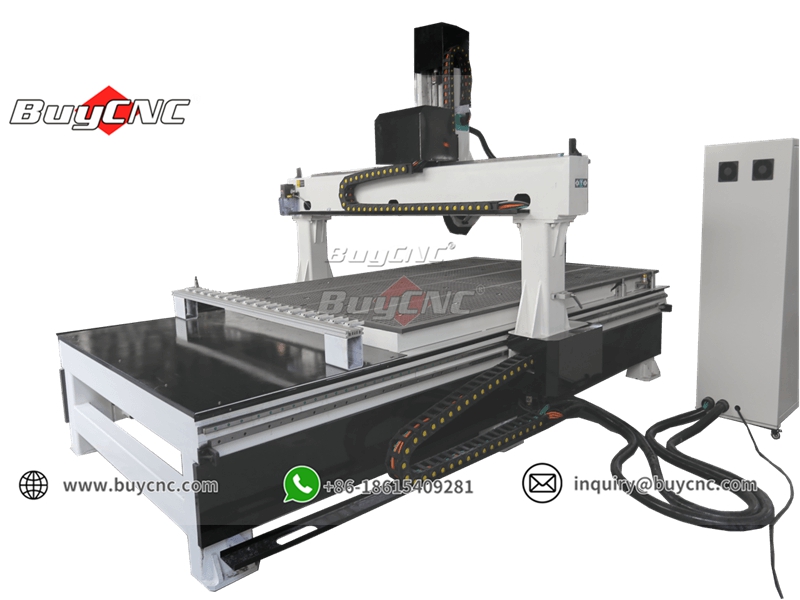

Installation of cnc wood carving machine

First, let’s talk about installation. After purchasing an cnc wood carving machine, professional installation service is the first step to ensure the normal operation of the equipment. During the installation process, technicians will conduct precise measurements and positioning based on the user’s site and needs to ensure that the cnc wood carving machine can be stably placed in the appropriate location. In addition, they will be responsible for connecting necessary equipment such as power supply and air source, and conducting preliminary functional tests. This kind of installation service not only ensures that the equipment can be put into use quickly, but also effectively avoids equipment failures caused by improper installation.

Debugging of cnc wood carving machine

Next is the debugging phase. After installation is complete, professional commissioning services are essential. During the debugging process, technicians will carefully adjust various parameters of the cnc wood carving machine to ensure that it reaches the best working condition. This includes adjusting key parameters such as engraving speed, depth, and accuracy, as well as testing the stability and reliability of the equipment. Through debugging, users can ensure that the cnc wood carving machine can perform efficient and accurate processing according to their needs.

After-sales service of cnc wood carving machine

Finally, let’s talk about after-sales service. After-sales service is the most critical part after purchasing an cnc wood carving machine. An excellent after-sales service team can provide users with timely and professional technical support and solve various problems encountered during the use of the equipment. Whether it is equipment failure, operation problems or maintenance, the after-sales service team can provide effective solutions. In addition, some manufacturers will provide regular equipment inspection and maintenance services to ensure long-term stable operation of the equipment.

To sum up, the purchase of an cnc wood carving machine should include installation, debugging and after-sales service. These services not only ensure the normal operation and long-term stability of the device, but also provide users with a better user experience. Therefore, when choosing an cnc wood carving machine, users should give priority to manufacturers that can provide one-stop solutions. Such manufacturers can not only provide high-quality equipment, but also provide users with a full range of service support, allowing users to truly use the cnc wood carving machine with confidence and satisfaction.

Of course, users should also pay attention to some other factors when purchasing an cnc wood carving machine, such as equipment performance, price, brand reputation, etc. But in any case, installation, commissioning and after-sales service are important links that cannot be ignored. Only by ensuring that these links are properly handled can users truly enjoy the convenience and benefits brought by the cnc wood carving machine.

Finally, we remind users that when purchasing an cnc wood carving machine, be sure to clarify the installation, debugging and after-sales service content and standards with the manufacturer or seller. At the same time, you can also refer to the reviews and feedback of other users to have a more comprehensive understanding of the service quality and reputation of the manufacturer or seller. Only in this way can we ensure that we receive all-round support and services after purchasing the cnc wood carving machine, so that the equipment can maximize its value.